Capacitive proximity switch sensor

A technology of proximity switches and sensors, applied in the field of sensors, can solve the problems of unfavorable long-term stability of capacitive proximity switches, short detection distances of proximity switches, and inability to achieve long-distance detection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

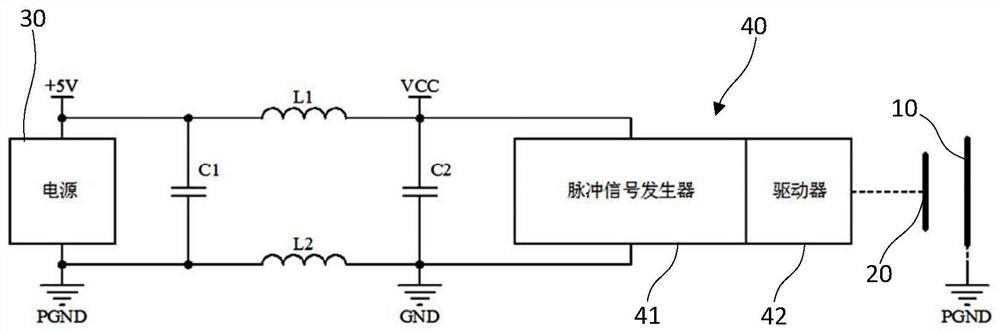

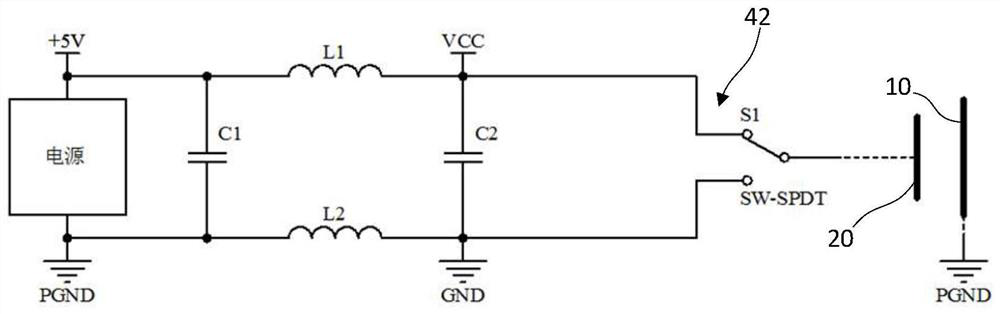

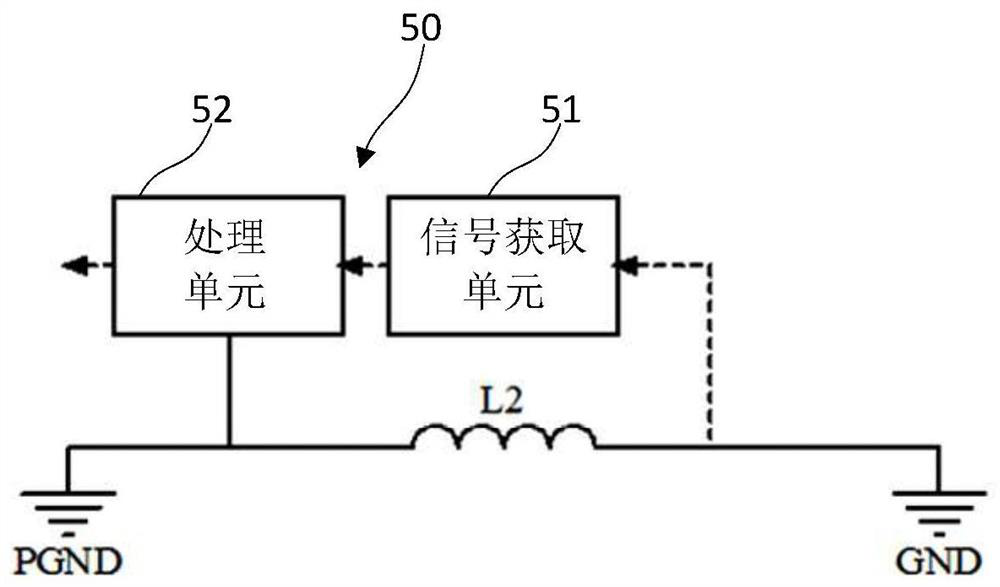

[0048] Such as figure 1 As shown, the embodiment of the present invention provides a capacitive proximity switch sensor for detecting the distance between it and the metal surface to be tested. The metal surface 10 to be tested is electrically connected to the ground terminal PGND, and the two potentials are the same. In this embodiment, the capacitive proximity switch sensor includes: a detection plate 20 , a power supply 30 , a driving module 40 and a signal processing module 50 . specific:

[0049]The detection pole plate 20 is set opposite to the metal surface 10 to be tested, and the two form an external capacitance. The metal surface 10 to be tested can adopt the surface of the metal component of the target, and its area is much larger than the area of the detection pole plate 20, so the effective area of the metal surface 10 to be tested is less affected by temperature, so that only the detection pole plate is included in the external capacitance 20 will be affe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com