Novel permanent magnet synchronous motor rotor structure

A permanent magnet synchronous motor and rotor structure technology, which is applied to synchronous machines, magnetic circuit shape/style/structure, control generators, etc., can solve the problems of difficult adjustment of the permanent magnet magnetic field, wide range of motor speed regulation, etc. The effect of large direct axis armature reaction, enhanced structural strength, and expanded speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

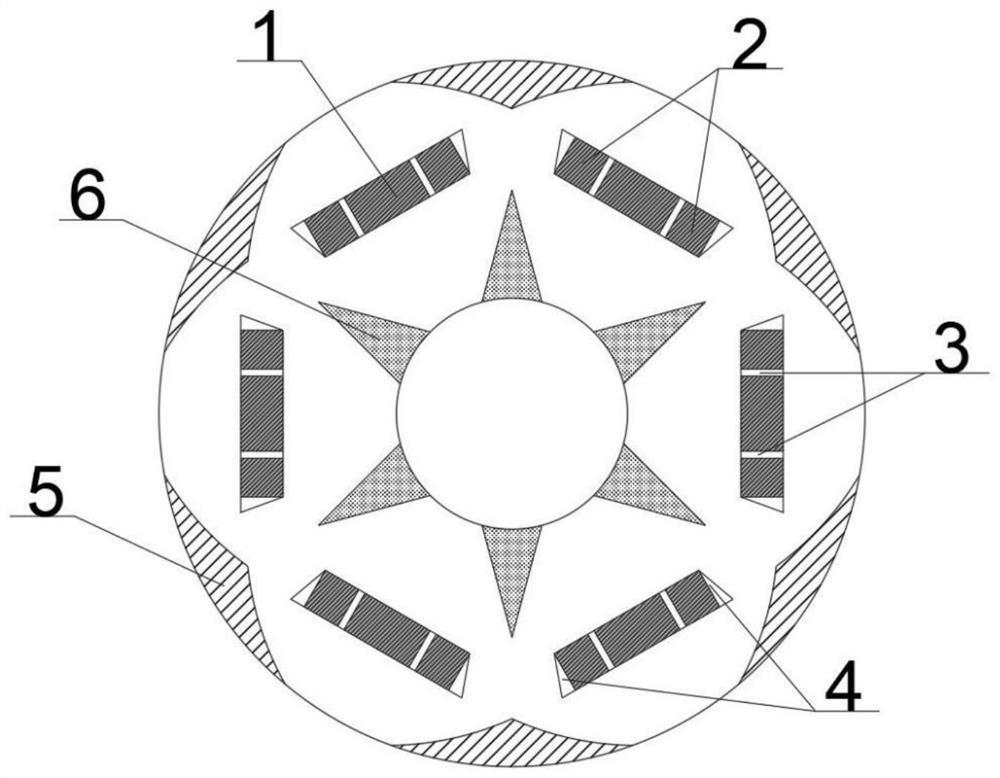

[0013] refer to figure 1 As shown in the figure, a new type of permanent magnet synchronous motor rotor structure adopts the technical scheme as follows: the motor rotor has a 6-pole structure, the 6-pole magnetic circuit is completely symmetrical, and the permanent magnet of each pole is a segmented structure, which is composed of three permanent magnets. There are main permanent magnets and auxiliary permanent magnets, each pole permanent magnet is embedded with a soft iron and a magnetic isolation baffle, a magnetic barrier is embedded on the outside of the rotor, and a non-magnetic conductive material is embedded on the inside of the rotor.

[0014] refer to figure 1 As shown, the ratio of the length of the main permanent magnet to the auxiliary permanent magnet of the motor is 2:1, the main permanent magnet is located in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com