Bearing assembly for cone crusher

A technology of cone crusher, bearing assembly, applied in the direction of bearings, bearings, shafts and bearings of rotating motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

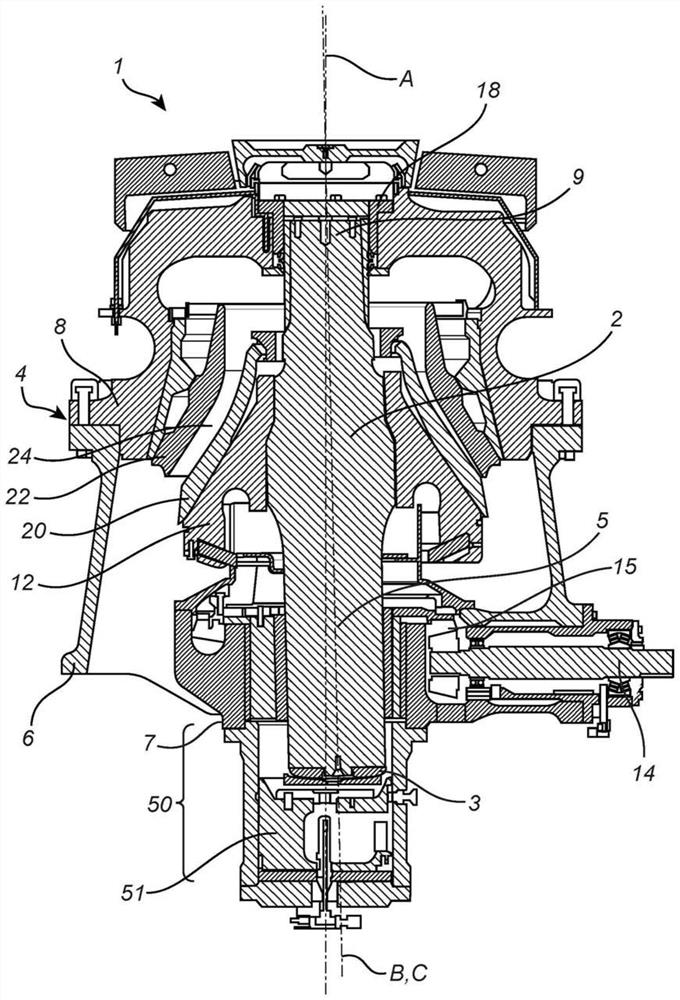

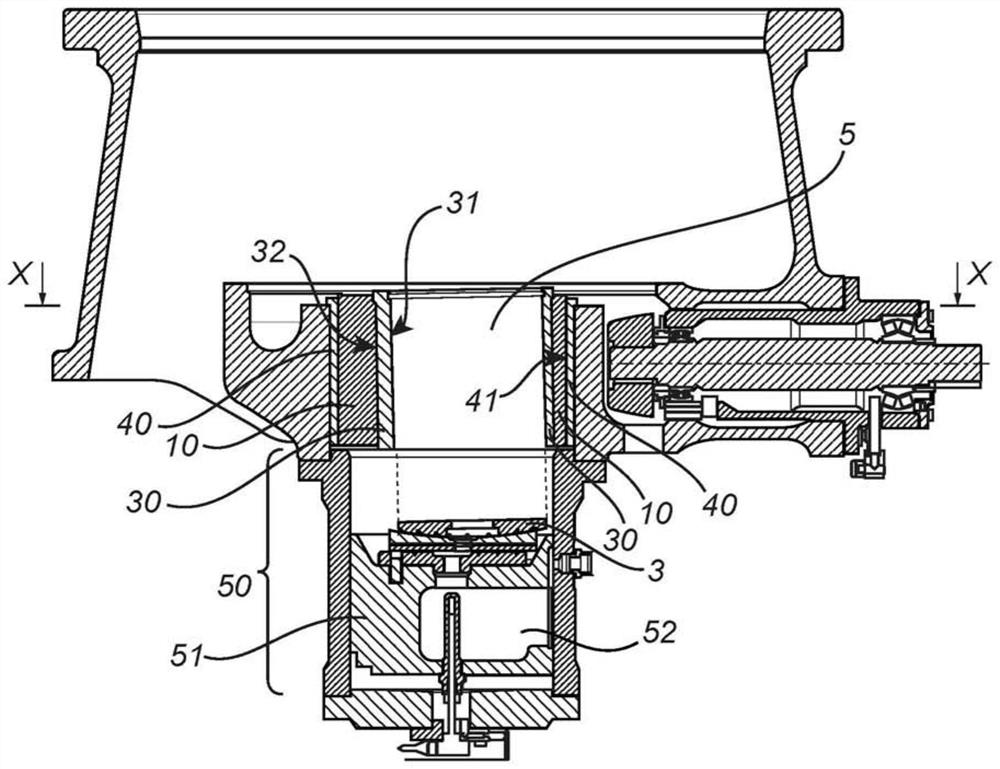

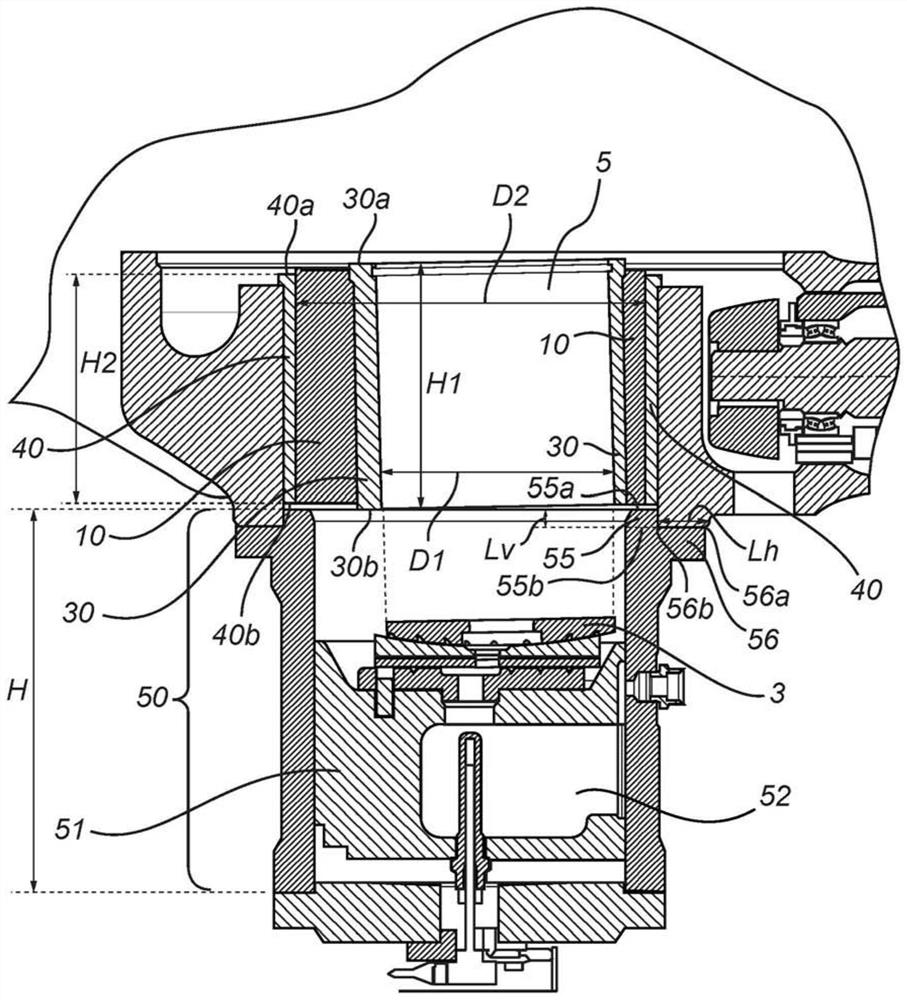

[0028] figure 1 A cone crusher 1 is disclosed having a vertical crushing head shaft 2 and a frame 4 with a bottom 6 and a top 8 . The breaker head shaft 2 has a lowermost end 3 arranged in connection with a hydrodynamic setting assembly 50 and is carried at its uppermost end 9 in a top bearing 18 in the frame top 8 . A crushing head 12 is mounted on the top of the head shaft 2 . The lowermost part 7 of the frame 4 is also arranged in connection with the hydraulic setting assembly 50 .

[0029] An eccentric sleeve 10 is arranged around the lower part 5 of the head shaft 2 . A drive shaft 14 is arranged to rotate the eccentric sleeve 10 via a motor (not shown) and a ring gear 15 mounted on the eccentric sleeve 10 . When the crusher is in operation, the drive shaft 14 rotates the eccentric sleeve 10 so that the crushing head shaft 2 and the crushing head 12 will perform a rotary motion.

[0030] The crushing head shaft 2 is radially supported at its lower part 5 in the eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com