Round steel material marking detection device and detection method, and method for manufacturing steel material

A technology of marking detection and round steel, which is applied to the marking at the position for detection. In the field of steel manufacturing, it can solve problems such as steel fracture, and achieve the effect of reducing the risk of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings. The embodiments shown below are examples of devices and methods for actualizing the technical idea of the present invention, and the technical idea of the present invention does not define the materials, shapes, structures, arrangements, etc. of components to the following embodiments. In addition, the drawings are schematic. Therefore, it should be noted that the relationship, ratio, and the like between the thickness and the planar dimensions are different from reality, and the relationship and ratio of mutual dimensions are also different among the drawings.

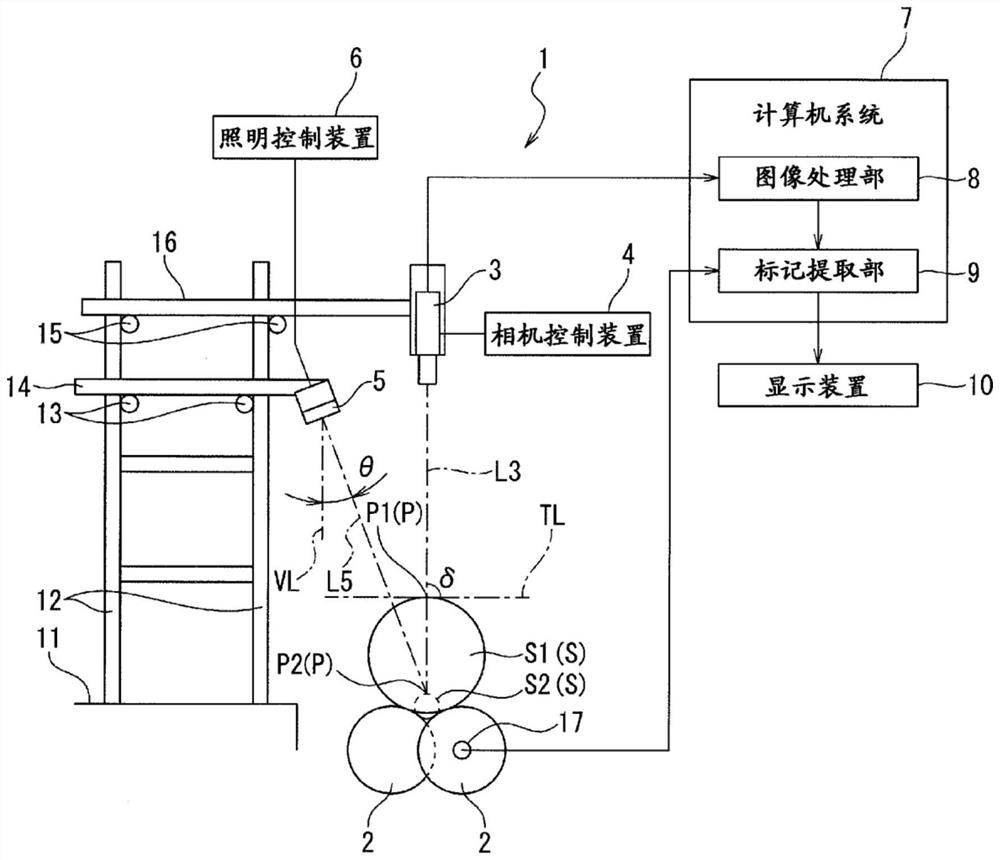

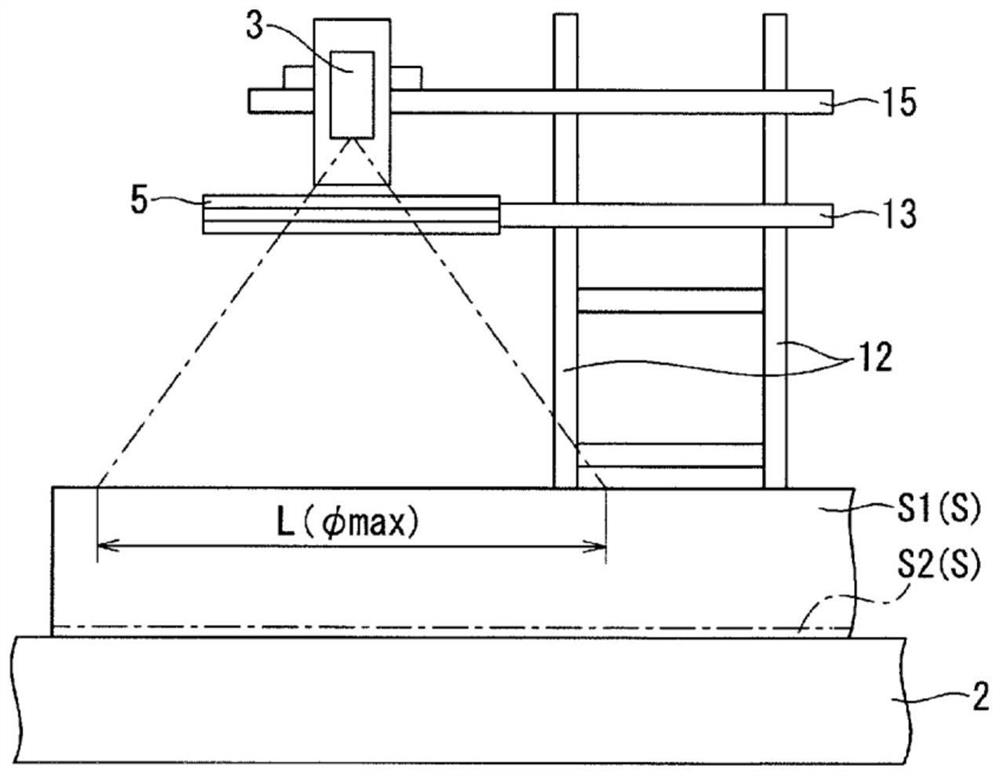

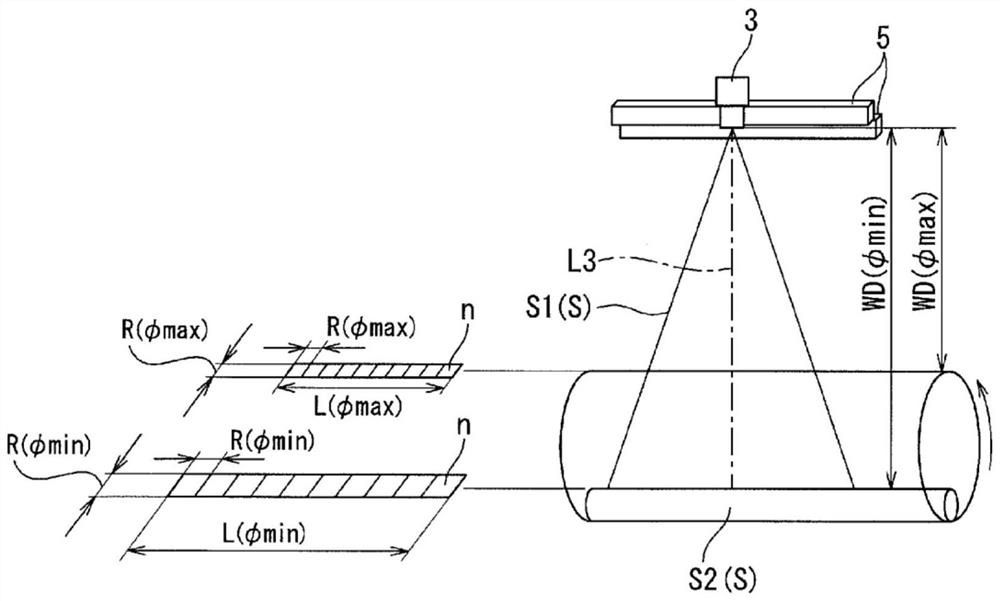

[0030] exist figure 1 The schematic structure of the round steel mark detection device 1 according to one embodiment of the present invention is shown in fig. side. The marking device is installed in the middle of the conveyance route for conveying the round steel S to the downstream process, and the marki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com