Semiconductor structures and methods of forming them

A technology of semiconductor and gate structure, which is applied in the field of semiconductor structure and its formation, can solve the problems of increased difficulty in the manufacturing process of fin field effect transistors, poor performance of fin field effect transistors, and decreased reliability, so as to reduce the risk of missing , Improve production yield and device reliability, and ensure the effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As mentioned in the background art, as the density of semiconductor devices increases and the size shrinks, the performance and reliability of the formed fin field effect transistors deteriorate.

[0033] During the etching process for removing the dummy gate oxide layer, the isolation layer at the bottom of the first opening is etched simultaneously, which increases the risk of a short circuit between the gate and the source region or the drain region. As the size of the FinFET becomes smaller, the risk of the short circuit is greater, and the influence on the reliability of the device is more obvious. It will be described below in conjunction with the accompanying drawings.

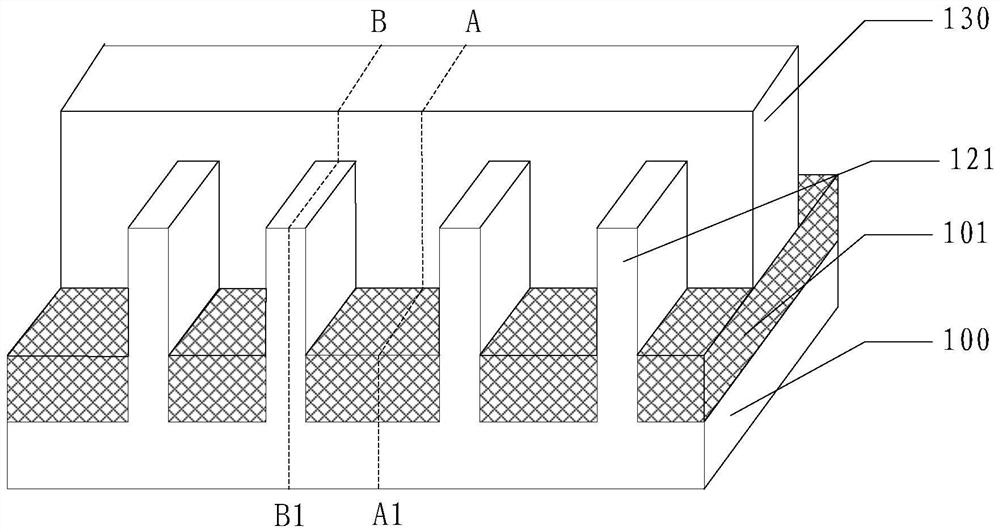

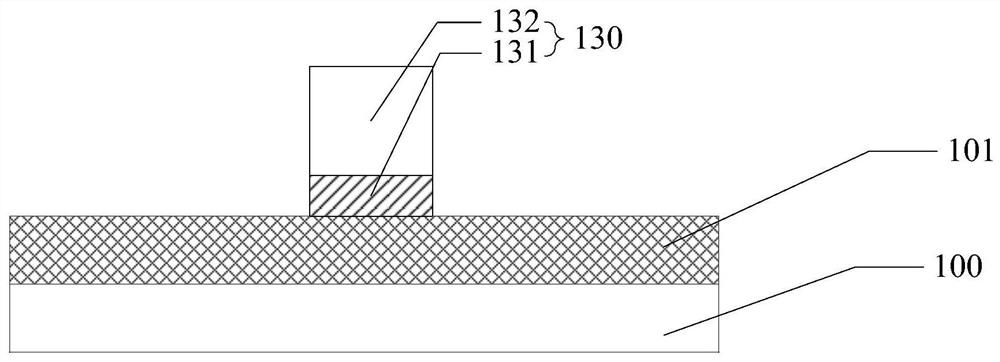

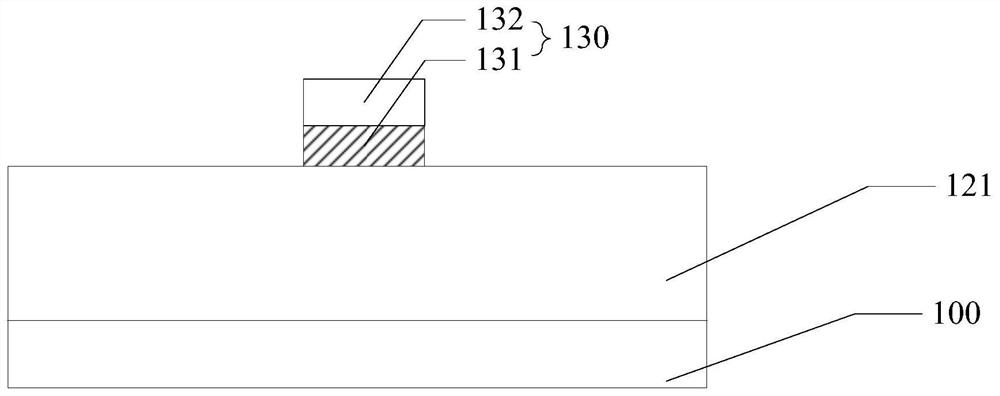

[0034] Figure 1 to Figure 6 It is a structural schematic diagram of each step of a method for forming a semiconductor structure.

[0035] Please refer to figure 1 , figure 2 and image 3 , figure 1 is a schematic diagram of the local three-dimensional structure, figure 2 for figure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com