Polyurethane-based composition

A composition and polyurethane technology, applied in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve problems such as inappropriate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0412] Example 1: Preparation of polyurethane-based composition A-1 with terminal groups T based on polyether polyol and polyester polyol prepare

[0413]190.7 g of Scuranate® TX and 100 g of ethyl acetate were introduced into the reactor and heated to 40°C. Then 22.7 g of Voranol® CP 450 and then 103.3 g of Voranol® P 400 are added successively, taking care to ensure that the temperature of the mixture does not exceed 80 °C. When the temperature of the mixture stabilized, the mixture was heated at 80-85°C for about 1 hour and then cooled to 70°C. 321.6 g of Realkyd® XTR 10410 were then introduced, taking care to ensure that the temperature of the mixture did not exceed 90°C.

[0414] The mixture was kept at 90°C for about 3 hours. The end of the reaction is monitored by controlling the mass percentage of NCO functional groups in the medium, which theoretically needs to be about 5.7%. When the reaction was complete, the mixture was cooled to 70 °C and 166.4 g of 2-hydro...

Embodiment 2

[0416] Example 2: Preparation of polyurethane-based composition A-2 with terminal groups T based on polyether polyol and polyester polyol prepare

[0417] 143.2 g of Scuranate® TX and 100 g of ethyl acetate were introduced into the reactor and heated to 40°C. 22.6 g of Voranol® CP 450 were added slowly and the mixture was heated to 50°C. Then 101.6 g of Voranol® P 400 are added. The reaction mass rose to about 70°C in an exotherm. Once the exotherm was under control, the mixture was maintained at 70°C. After 1 hour of reaction, 241.4 g of Realkyd® XTR 10410 was added. The reaction mass rose in an exotherm up to about 85°C. The mixture was maintained at 85°C for about 2-3 hours. The end of the reaction is monitored by controlling the mass percentage of NCO functional groups in the medium, which theoretically must be about 4.4% by weight. After the reaction was complete, the mixture was cooled to 70°C and 76.6 g of Desmodur® N3300 were introduced. The mixture was homo...

Embodiment 3

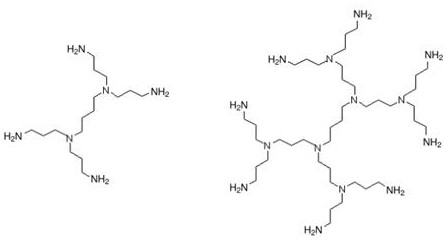

[0419] Embodiment 3: the preparation of composition B

[0420] Composition B that has been tested was prepared by simply mixing diamine B1 (Jeffamine® ED148 or H 2 N-(CH 2 ) 10 -NH 2 ) and / or polyamine B2 (Lupasol® FG), its B1 / B2 weight ratio is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com