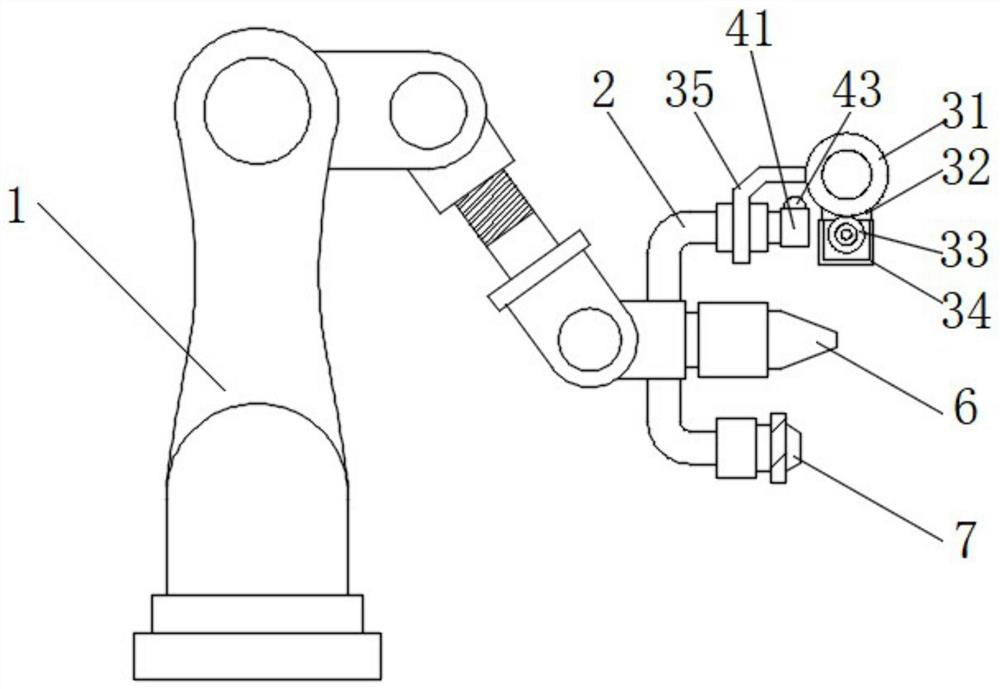

Mechanical spraying device, spraying mechanical arm and automatic spraying method

A technology of mechanical spraying and spraying powder, which is applied in the field of mechanical arms, can solve the problems that the application roller cannot be applied, the application effect of the roller is not good, and the powder is not easy to stick, etc., to achieve simple structure, reduce time-consuming and labor-intensive, and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

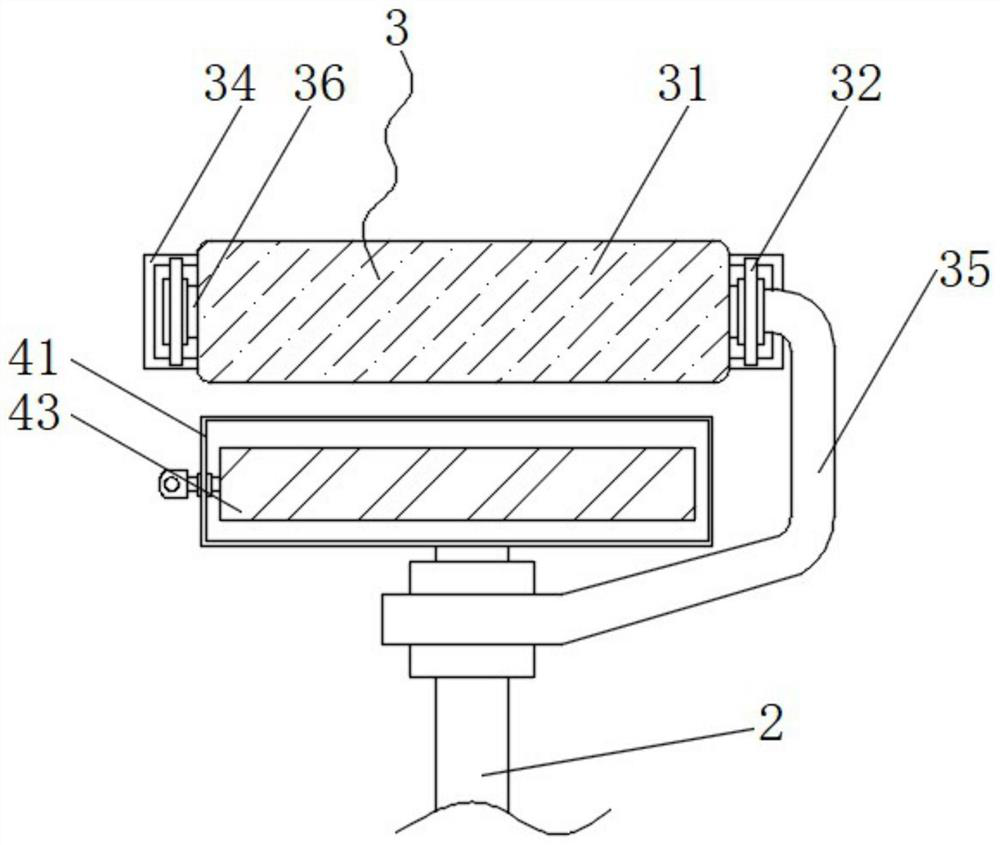

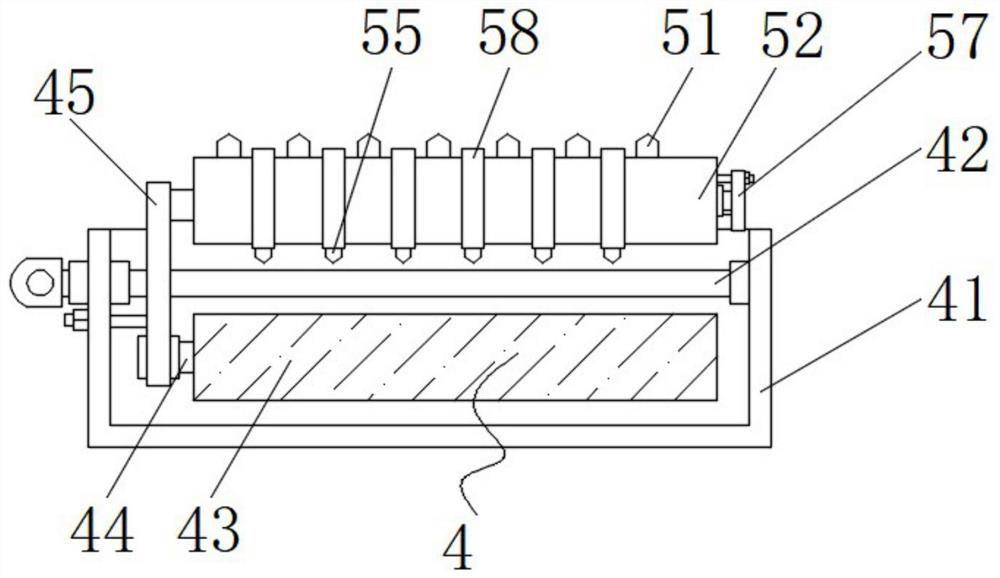

[0063] In the foregoing embodiments of the present invention, a mechanical spraying device is provided, and based on the mechanical spraying device, a spraying mechanical arm and a method for automatic spraying are provided, by connecting the coating assembly 3 with the surface of the object to be sprayed, The coating assembly 3 is driven by the cleaning assembly 4 to evenly apply the solvent to the surface of the object to be sprayed, and the solvent output by the coating assembly 3 is recovered, and then the powder is sprayed on the spraying part 6. The surface of the object to be sprayed, the powder is bonded to the surface of the object through a solvent, and the position of the cleaning assembly 4 and the impurity removal assembly 5 is adjusted so that the impurity removal assembly 5 is attached to the coating assembly 3 combined, so that the impurity removal component 5 scrapes off the debris generated on the outer wall of the coating component 3; the device is simple in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com