Rapid drying device for automobile part paint spraying

A technology for fast drying and auto parts. It is used in devices for coating liquids on surfaces, pretreatment surfaces, coatings, etc. It can solve problems such as shortened paint life, paint wrinkles, paint damage, etc., to reduce mobile operation panels. time, prolong service life and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

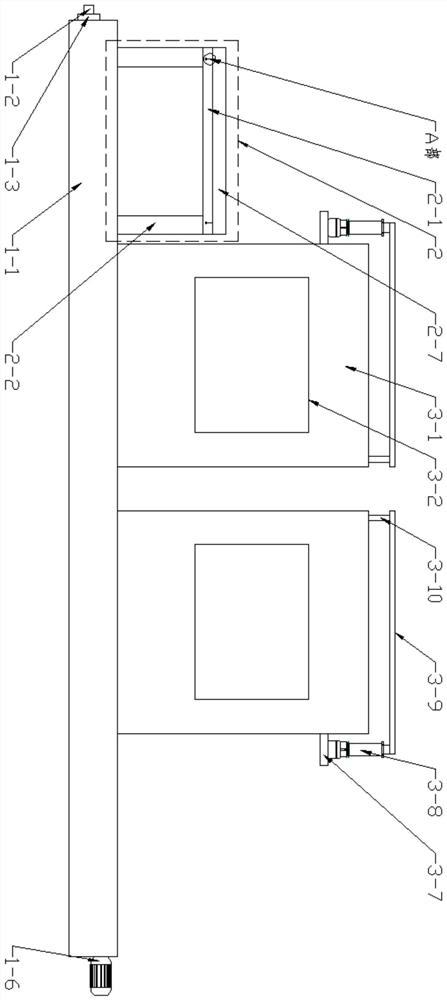

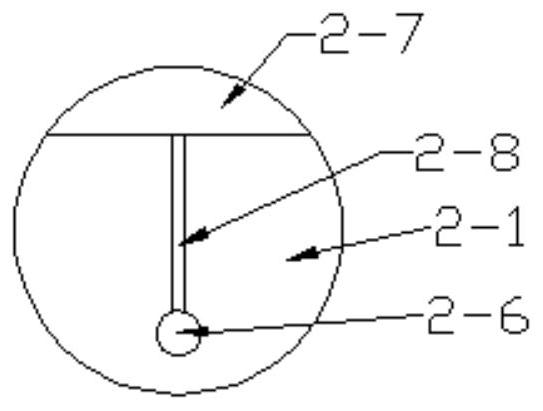

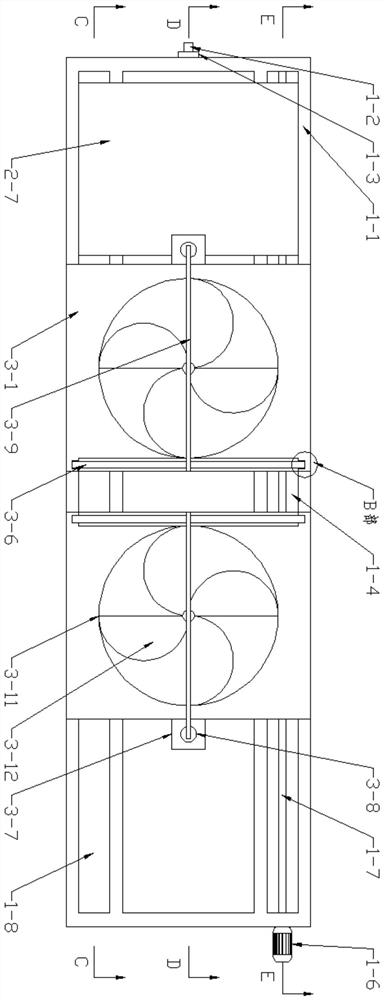

[0032] see as Figure 1 to Figure 10As shown, the technical solution adopted in this specific embodiment is: it includes a support mechanism 1, an operating mechanism 2 and a drying mechanism 3; the support mechanism 1 includes a bottom box 1-1, a drain pipe 1-2, a valve 1- 3. Screw rod 1-5, motor 1-6 and screw nut 1-7; the left side wall of the bottom box 1-1 is connected with a drain pipe 1-2, and the drain pipe 1-2 is provided with a valve 1-3 , regularly open the valve 1-3 to facilitate the cleaning of the bottom box 1-1; the rear side of the upper surface of the bottom box 1-1 is provided with a No. 1 chute 1-4, and the left end of the screw rod 1-5 passes through the bearing and the No. 1 chute The left side wall of 1-4 is screwed, and the right end of screw rod 1-5 is screwed through the bearing to pass through the right side wall of No. 1 chute 1-4, and is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com