Constant temperature cooling device for daily chemical packaging injection mold

A technology of constant temperature cooling and injection mold, applied in the field of plastic product production and processing, can solve the problems of rapid temperature rise, difficult feeding, raw material temperature rise, etc., and achieve the effects of increasing cooling efficiency, large detection range, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

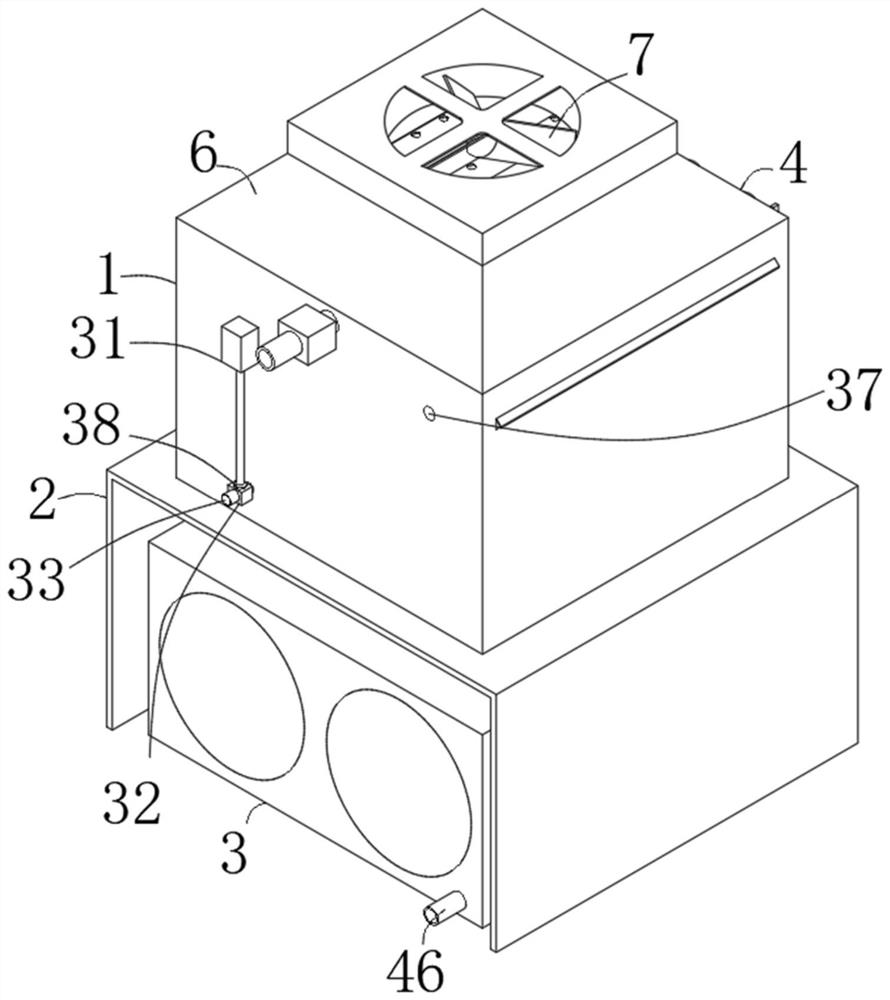

[0033] see Figure 1-2and 5-6, the present invention provides a technical solution: a large-scale accurate measurement of the water temperature at the bottom of the cooling water tower 1, and a constant temperature cooling device for daily chemical packaging injection molds that automatically controls the cooling efficiency, including the cooling water tower 1 and the steel platform of the water tower 2. The cooling water tower 1 is installed above the water tower steel platform 2, and is used to cool the water that completes a cooling cycle; the cooling water tank 3, the cooling water tank 3 is installed at the bottom of the water tower steel platform 2, and is used to store cooling Water; cooling device 4, described cooling device 4 is installed in cooling water tower 1 away from an end of water tower steel platform 2, and is used for cooling water; Detection device 5, described detection device 5 is installed in cooling water tank 3 bottoms, and uses To detect the water tem...

Embodiment 2

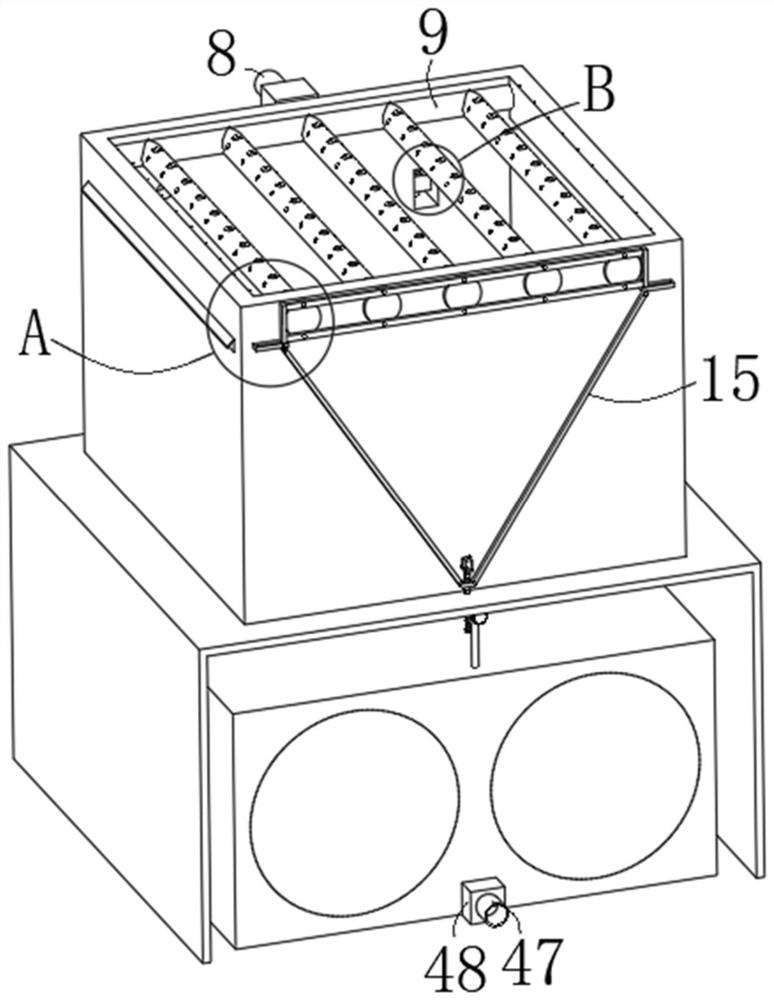

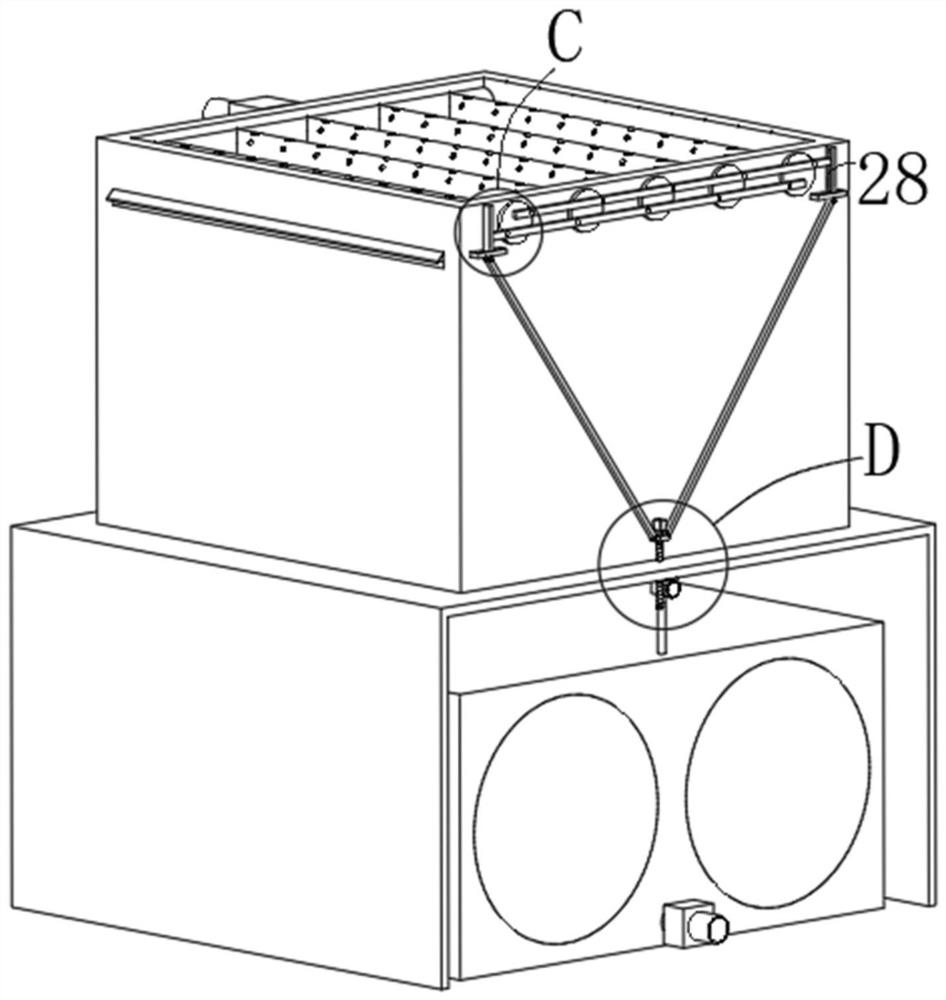

[0038] see image 3 and 7 -8. The present invention provides a technical solution: a large-scale and accurate measurement of the water temperature at the bottom of the cooling water tower 1, and a constant temperature cooling device for daily chemical packaging injection molds that automatically controls the cooling efficiency, including the cooling water tower 1 and the steel platform 2 of the water tower. The cooling water tower 1 is installed on the top of the water tower steel platform 2, and is used to cool the water that completes a cooling cycle; the cooling water tank 3, the cooling water tank 3 is installed on the bottom of the water tower steel platform 2, and is used to store cooling water; Cooling device 4, described cooling device 4 is installed on cooling water tower 1 away from one end of water tower steel platform 2, and is used for cooling water; Detection device 5, described detection device 5 is installed in cooling water tank 3 bottoms, and is used for The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com