A kind of elevator guide rail automatic installation equipment and method

An automatic installation and elevator guide rail technology, which is applied in the direction of transportation and packaging, elevators, etc., can solve the problems of strict installation requirements, heavy installation workload, time-consuming and labor-consuming, etc., and achieve the goal of eliminating danger, improving construction efficiency and reducing construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

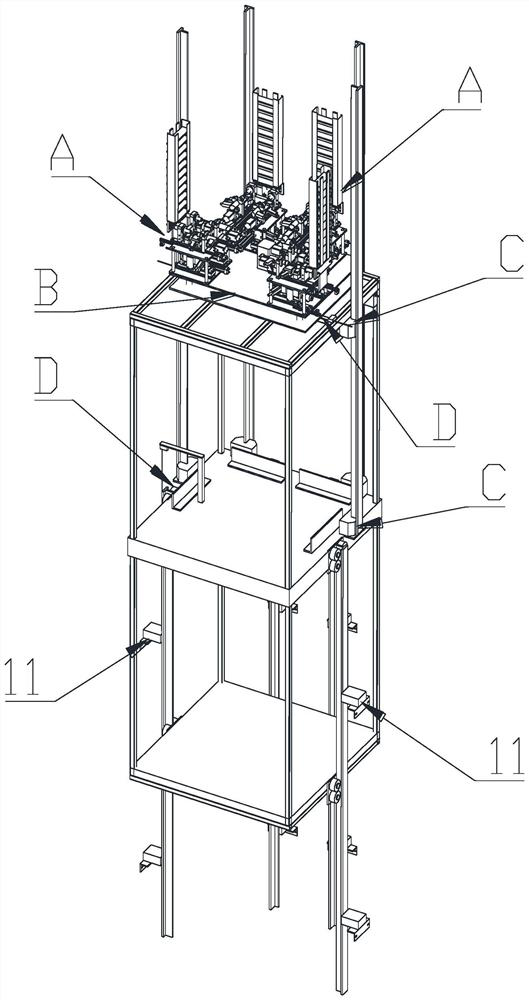

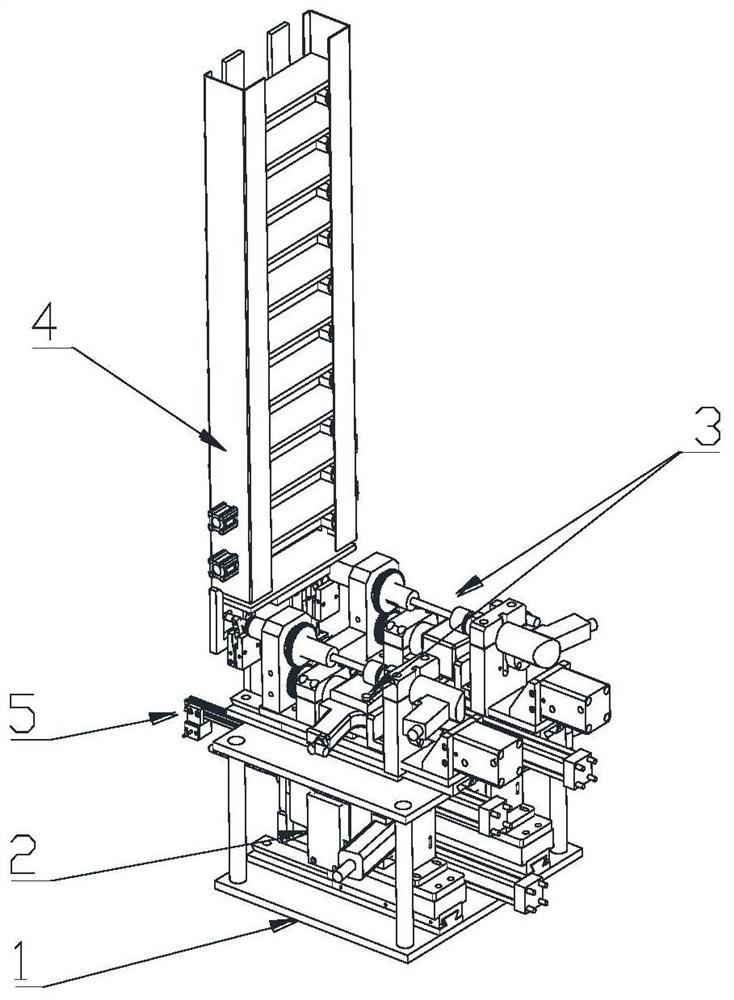

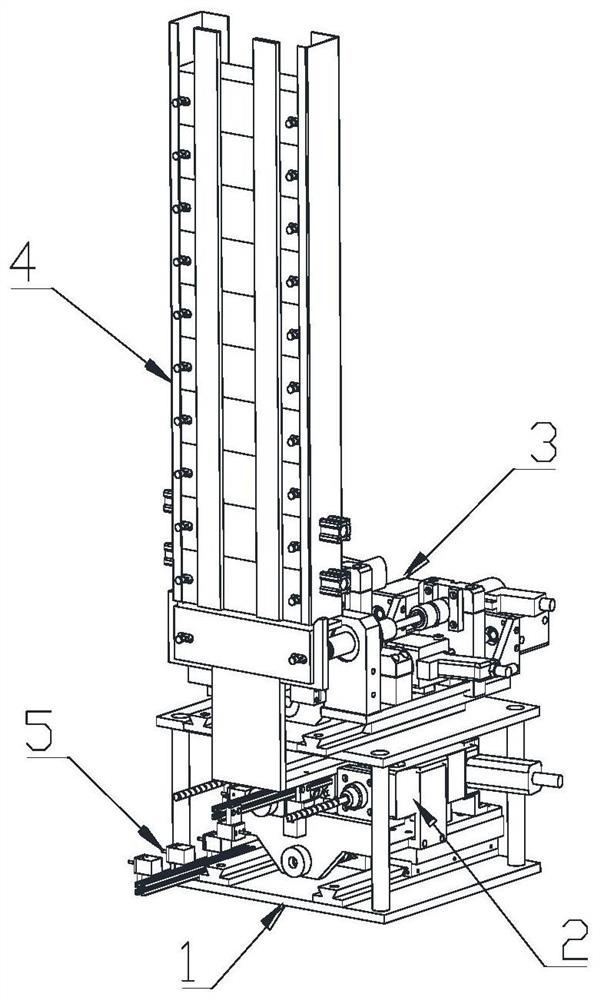

[0037] see Figure 1-Figure 17 , The elevator guide rail automatic installation equipment of the present invention includes a lift box B, a bottom code automatic installation device A, a guide rail transport device C and a distance measuring device D arranged on the lift box B.

[0038] The specific structures of the bottom code automatic installation device A, the lifting box B, the guide rail conveying device C, and the distance measuring device D are described in detail below.

[0039] (1) Lifting box B

[0040] see Figure 1-Figure 17 , the lifting box B is located in the hoistway, the lifting box B is at least two-layer structure, and different automatic construction modules and part of the space can be arranged according to needs for manual operation; wherein, the bottom code automatically There are multiple sets of installation devices A, and multiple sets of bottom code automatic installation devices A are installed on the upper platform of the lifting box B; Multip...

Embodiment 2

[0089] see Figure 1-Figure 17 , the present invention utilizes automatic construction operation to install the guide rail in the elevator shaft and the basic fastener of the door cover, and its construction operation method is as follows: (note: the construction device referred to below not only includes the elevator automatic installation system of the present invention, but also Including auxiliary construction equipment required for installation by construction personnel)

[0090] (1) Measure the shaft, install the plumb line of the guide rail and the door cover

[0091] Measure the hoistway to confirm whether the wall of the hoistway is out of tolerance or the verticality is out of tolerance, and whether it needs to be rectified to meet the requirements of construction standards.

[0092] Install the plumb line of the guide rail and the door cover. The plumb line is usually straightened along the direction of the plumb by a piano wire with a diameter of 0.5-1mm and fixed...

Embodiment 3

[0109] see Figure 18-Figure 22 , the difference between this embodiment and Embodiment 1 is:

[0110]The guide rail handling device C includes a guide rail alignment moving mechanism 8 arranged on the lifting box B for transporting the guide rail to the corresponding guide rail bracket, wherein the guide rail positioning moving mechanism 8 includes a guide rail positioning moving mechanism 8 arranged on the lifting box body. A guide rail clamp on the platform of B for clamping the guide rail and a guide rail transport drive mechanism for driving the guide rail clamp to move to the guide rail bracket; wherein,

[0111] The guide rail clamping member includes a first clamping member 8-6 and a second clamping member 8-1 arranged on the lifting platform of the lifting box B, wherein the second clamping member 8-1 is arranged on the The lifting box B is located on the lifting platform below the first clamping member 8-6, wherein the first clamping member 8-6 is an electromagnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com