Rigid photosensitive resin composition based on polyurethane acrylate and production method thereof

A polyurethane acrylate and photosensitive resin technology, which is applied in the field of rigid photosensitive resin compositions based on polyurethane acrylate, can solve problems such as poor mechanical properties, low precision of finished products, and hindering the development of photosensitive resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

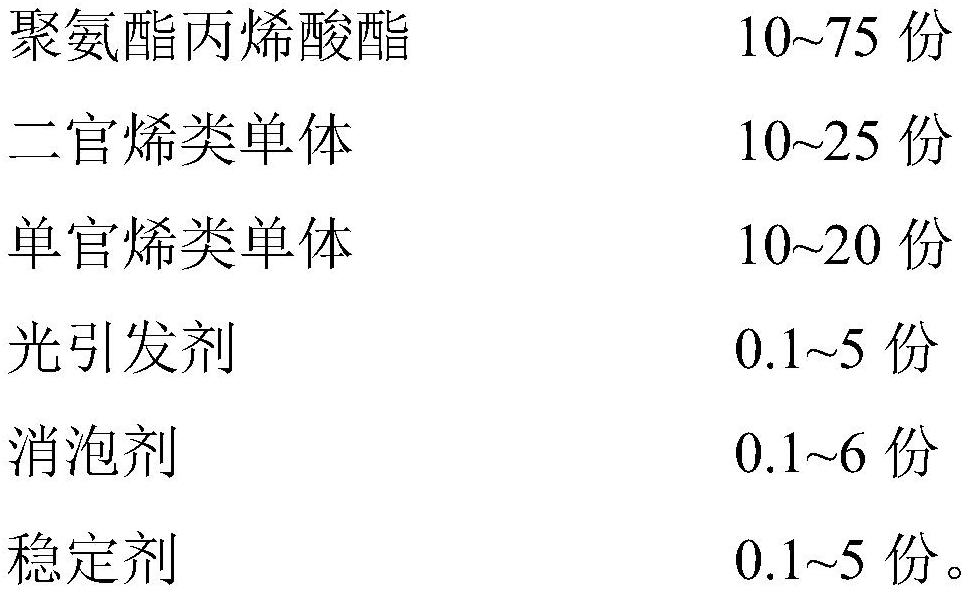

[0026] Under the condition of avoiding light, 300g of polyurethane acrylate prepolymer SL-01 (number average molecular weight 1000), 50g of 1,6-hexanediol diacrylate, 35g of hydroxyethyl methacrylate, 16g of Acryloylmorpholine, 8g of diphenyl-(2,4,6-trimethylbenzoyl)phosphine, 4g of hydroquinone, and 5g of defoamer were stirred evenly to obtain photosensitive resin A1.

Embodiment 2

[0028] Under the condition of lucifuge, with the polyurethane acrylate prepolymer SL-01 (number average molecular weight 1000) of 300g, the tripropylene glycol diacrylate of 50g, the hydroxyethyl methacrylate of 35g, the acryloyl morpholine of 16g, 8g of diphenyl-(2,4,6-trimethylbenzoyl)phosphine, 4g of hydroquinone, and 5g of defoamer were stirred evenly to obtain photosensitive resin A2.

Embodiment 3

[0030] Under the condition of lucifuge, the urethane acrylate prepolymer SL-02 (number average molecular weight 1000) of 300g, the isobornyl methacrylate of 50g, the hydroxyethyl methacrylate of 35g, the acryloylmorpholine of 16g , 8g of diphenyl-(2,4,6-trimethylbenzoyl)phosphine, 4g of hydroquinone, and 5g of defoamer were stirred evenly to obtain photosensitive resin A3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com