Robot system for monitoring horizontal displacement of foundation pit deep layer and automatic monitoring method

A robot system and horizontal displacement technology, applied in the field of measurement, can solve the problems of large positioning error, bulky cables, and large amount of instruments, so as to improve efficiency and accuracy, solve inefficiency, and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention adopts following technical scheme:

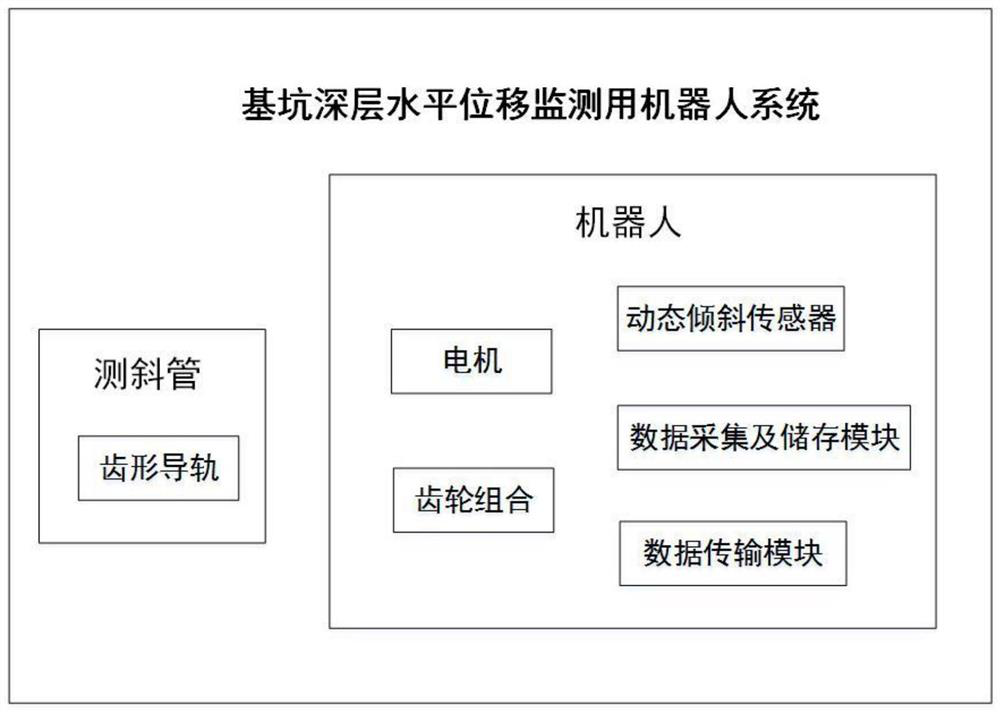

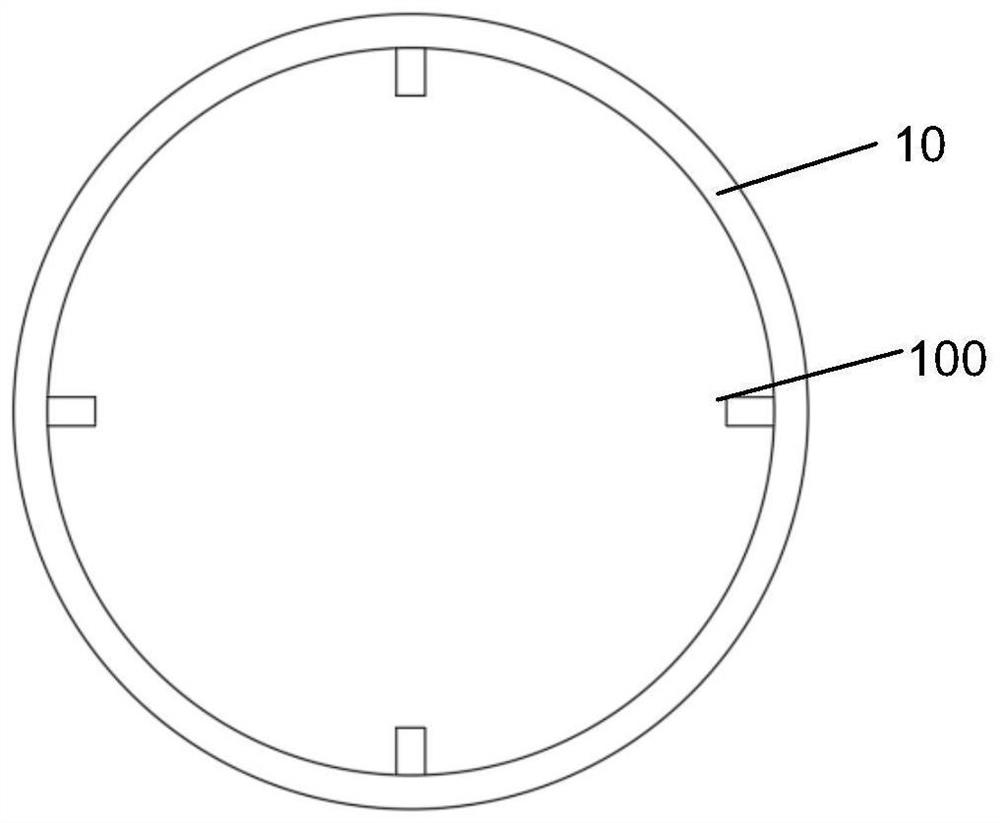

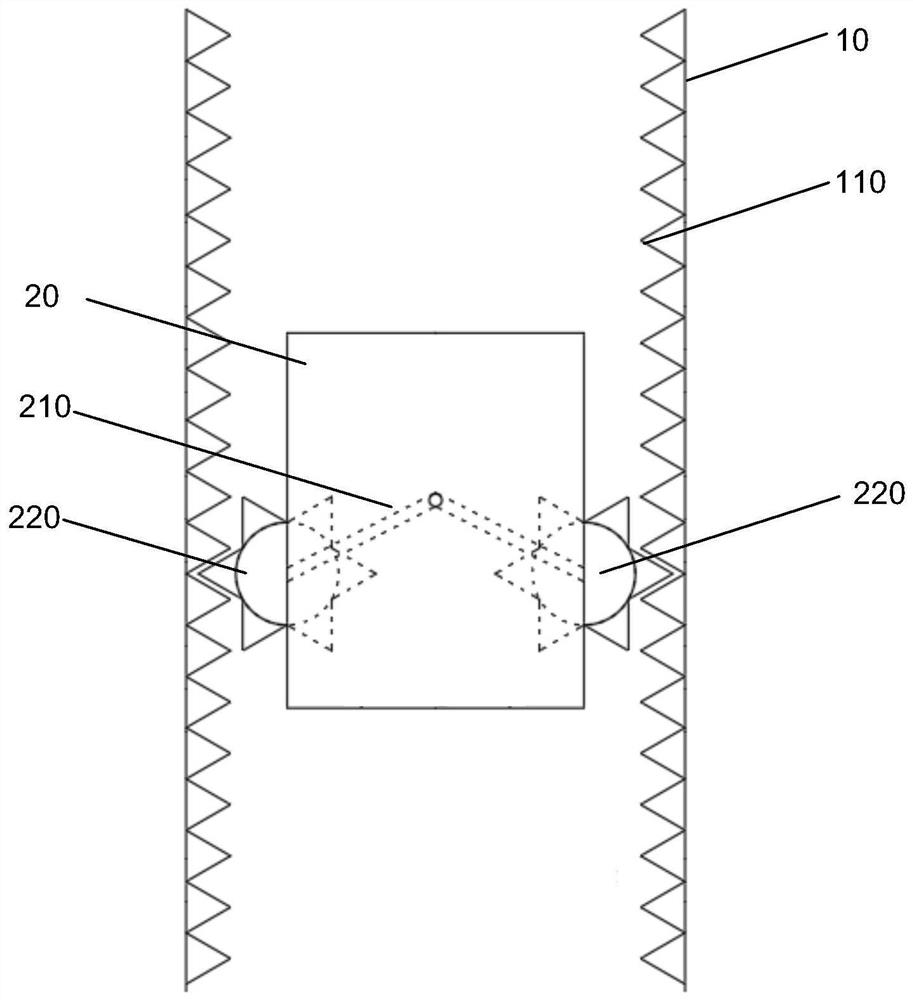

[0036] Such as figure 1 , the structural block diagram of the automatic monitoring system for deep foundation pit horizontal displacement in the embodiment of the present invention, comprising: a toothed guide rail and a motor-driven robot, the toothed guide rail is installed in the inner guide groove of the inclinometer tube; the robot is provided with a motor, Gear combination, dynamic inclination sensor, tooth number counter, data acquisition and storage module, data transmission module; the gear combination is matched with the toothed guide rail, and the motor drives the gear combination to run for the robot to move up and down in the inclinometer tube, and the gear The combination is connected with the robot through an active spring to adapt to the curvature of the inclinometer tube; the dynamic inclination sensor records the angle value of the robot at different positions; the tooth number counter position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com