Composite underwater power dredging drag harrow

A dredging and raking, composite technology, applied in mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problems of low work efficiency, slow construction progress and high project cost, To achieve the effect of convenient installation, convenient processing, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

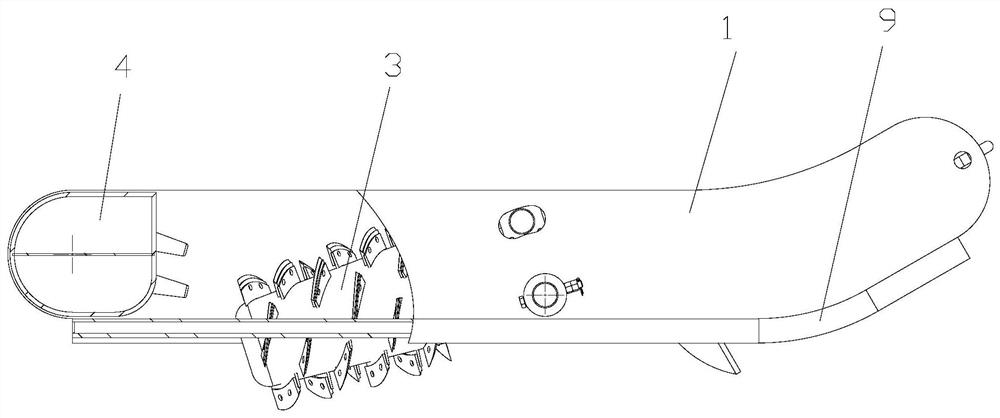

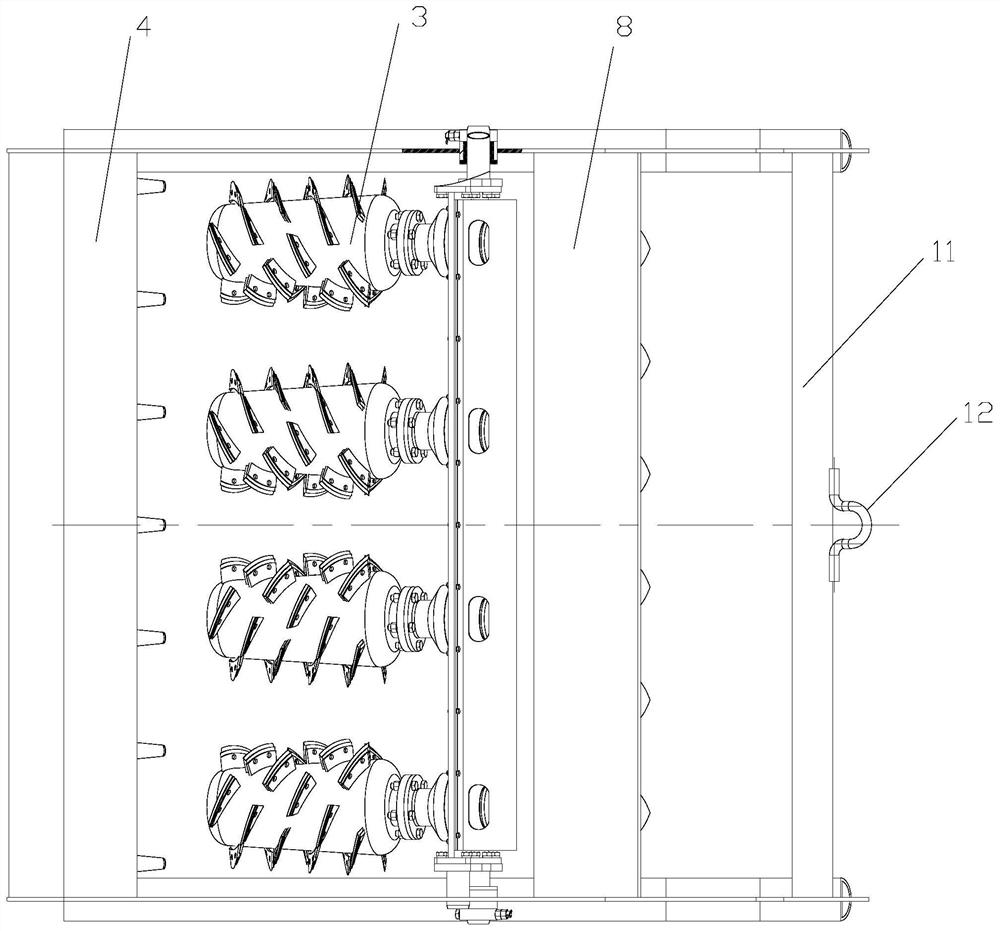

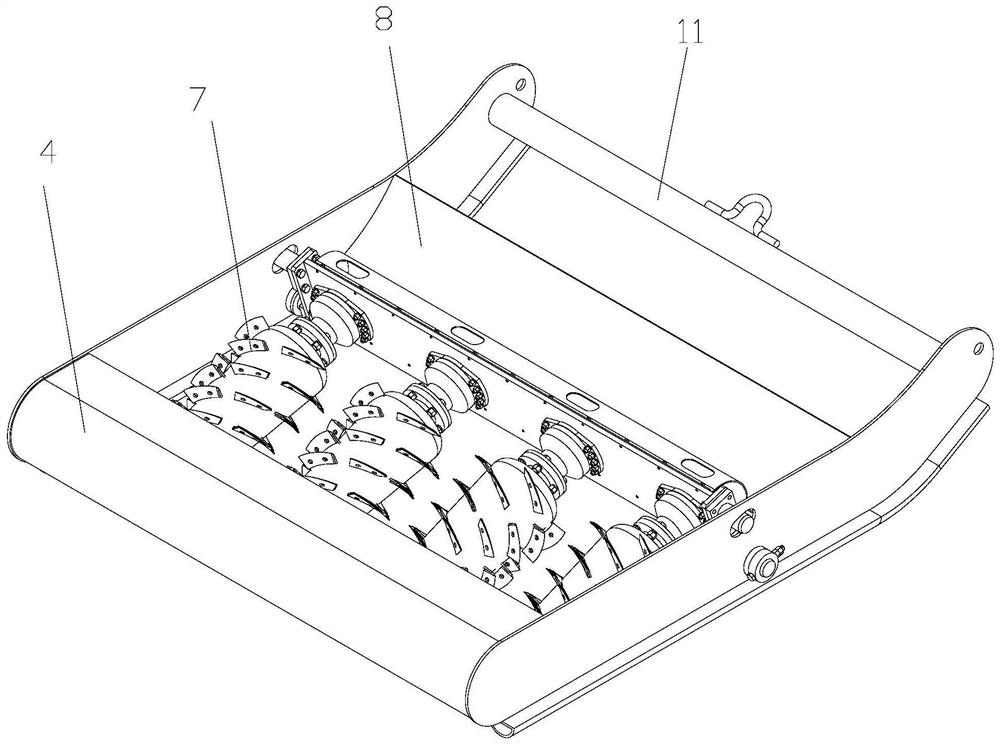

[0039] According to the present invention Figure 1-8 As shown, including the rack 1, further comprising a fixed harde 2, a power raft 3, and an air tank 4 disposed in sequential, which includes a pair of parallel disposed side panels 5, the fixed harde 2 fixedly connected to a pair of side Between the board, the power harrow 3 is actively coupled between a pair of side plates that are fixedly coupled between a pair of side plates.

[0040] The present invention is in operation, the rake of the raft includes a pair of side panels, and then sets the fixed hoe, power hoe and water tank in the front to rear, which is convenient to form an overall, easy to process, and improve the strength.

[0041] The fixed harrow, the power harde and the water tank are arranged in turn, the layout is reliable; when the ship sails, the 耙 耙 齿 切 切 切 切 切 切 将 将 将 将 将 将 将 将 扬 将 将 将 扬 将 将;;;;;;;;;;;;;;;; Forced cutting; water tank can spray water, jet action, water spray further broken plaster, the jet all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com