Rolling bearing fault diagnosis method and system based on ISA-SDAE

A rolling bearing and fault diagnosis technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., to achieve high accuracy, good feature learning ability, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

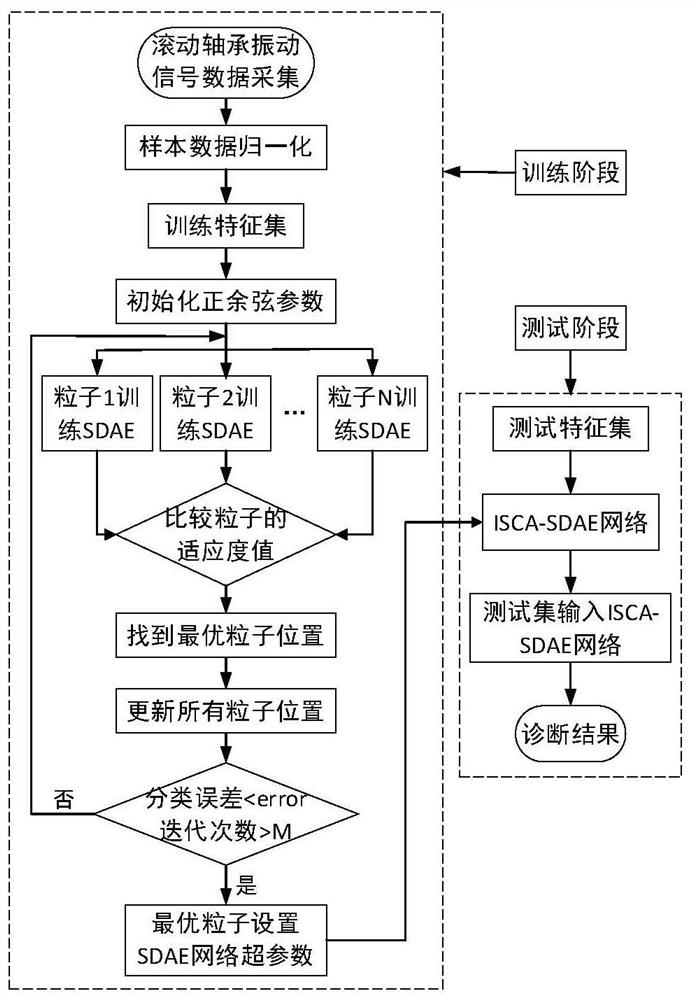

Method used

Image

Examples

Embodiment 1

[0100] (1) Experimental data

[0101] To obtain the data set, the vibration acceleration sensor ICM20948 collects seven vibration signals of the motor rolling bearing, and the collected data is input into the Raspberry Pi 3B+ through the wireless transmission module to obtain the motor vibration signal data set. Figure 7 It is the interface diagram of the diagnosis result of the motor bearing fault diagnosis system in the present invention. If the motor state is normal, the interface status type display light of the motor rolling bearing fault diagnosis system is green; if there is a fault point in the motor, the motor rolling bearing fault diagnosis system interface status type display The light is red. Figure 8 The vibration signal waveform interface diagram of the motor bearing fault diagnosis system is used to realize the waveform display of the motor bearing vibration signal and the reading of the historical vibration data of each motor; the type and code of the motor r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com