Diamond bead thread visual inspection equipment

A diamond beading, visual inspection technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of high thread error rate and low efficiency, and achieve the effect of efficient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the embodiments of the present invention will be described below with reference to the accompanying drawings.

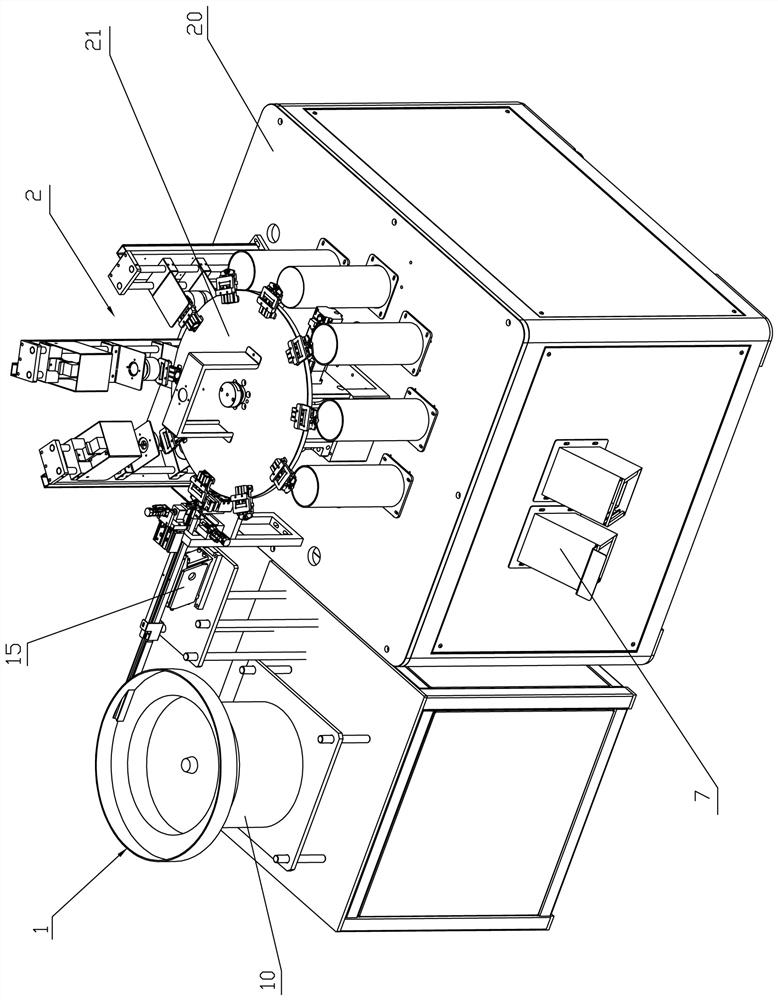

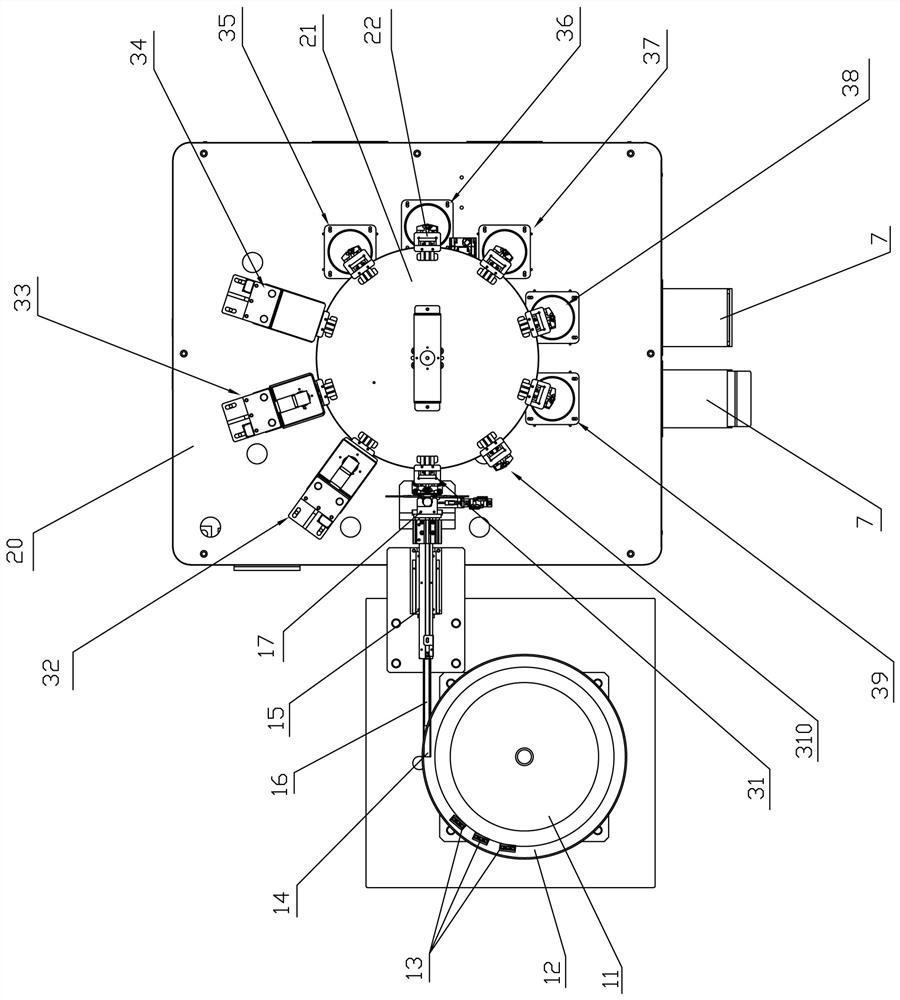

[0029] refer to Figure 1 to Figure 2 , a diamond bead thread visual detection device, comprising an automatic feeding vibration mechanism 1 and a visual detection mechanism 2, the automatic feeding vibration mechanism 1 is used to transport the beads to the visual detection mechanism 2, and the visual detection mechanism 2 takes pictures through the visual detection lens 4 And visual recognition system analysis and comparison, used to detect whether each parameter of the beading is up to standard.

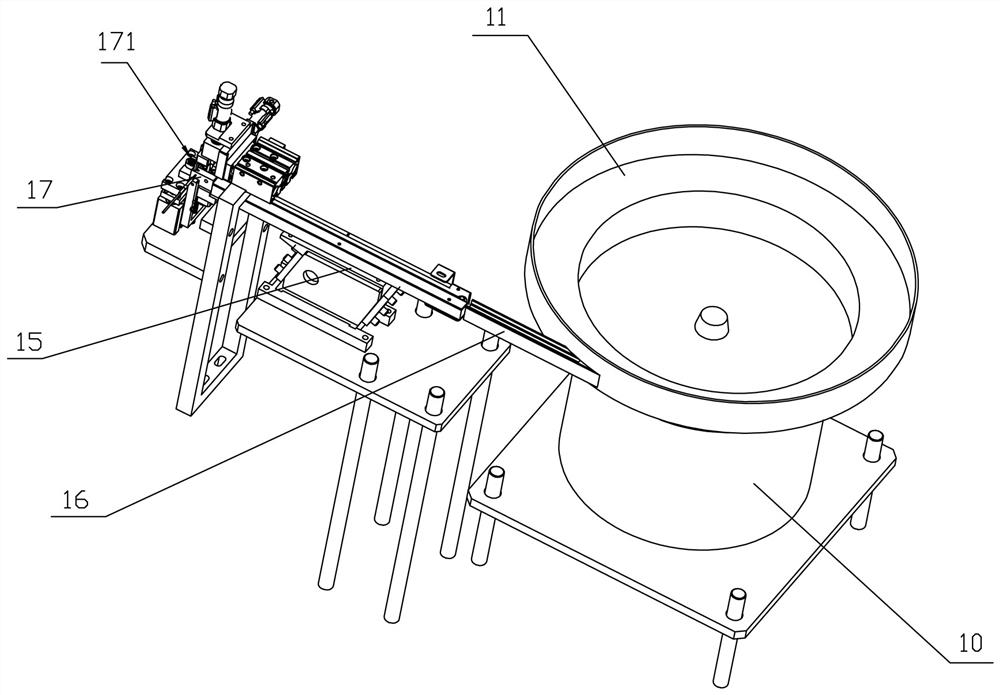

[0030] refer to figure 2 and image 3 , the automatic feed vibration mechanism 1 includes a vibrating plate feeder 10, the vibrating plate feeder 10 includes a container 11 in a semi-closed barrel structure, and the container 11 is spirally provided with an ascending track 12 for conveying beads, and the ascending track 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com