Fillet weld positioning method based on point cloud geometric features

A positioning method and geometric feature technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of high usage conditions and usage costs of welding systems, and achieve the effect of optimizing the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

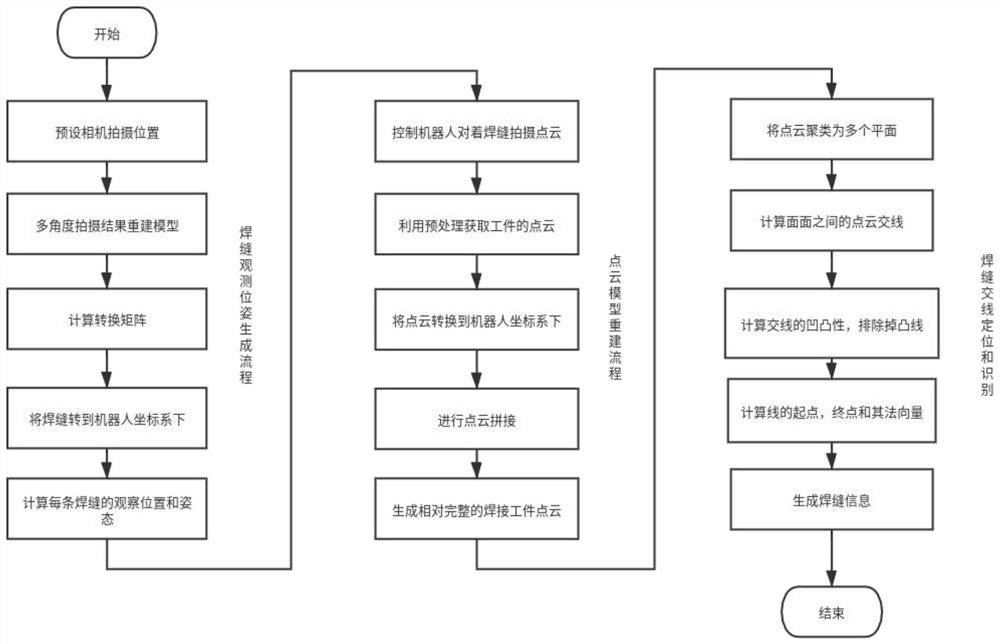

[0029] Such as figure 1 As shown, the fillet weld location method based on point cloud geometric features, the specific steps are as follows:

[0030] S1. Preset the initial position of the camera: control the robot to capture the point cloud at the corresponding position;

[0031] S2. Reconstructing the model from multi-angle shooting results: according to the multi-angle shooting results, use the iterative nearest point algorithm to stitch the point cloud to generate a reconstructed point cloud model;

[0032] S3. Calculate the transformation matrix: perform feature matching based on the fast point feature histogram of the point cloud and the digital model of the theoretical workpiece, and calculate the transformation matrix of the two;

[0033] S4, transfer to the robot coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com