A kind of nitration reactor for producing p-nitrotoluene from toluene

A technology for p-nitrotoluene and nitrification reactors, which is applied in the preparation of nitro compounds, chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, etc. There are many problems such as the limitation of increasing the rate, and the inability to effectively improve the degree of material mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

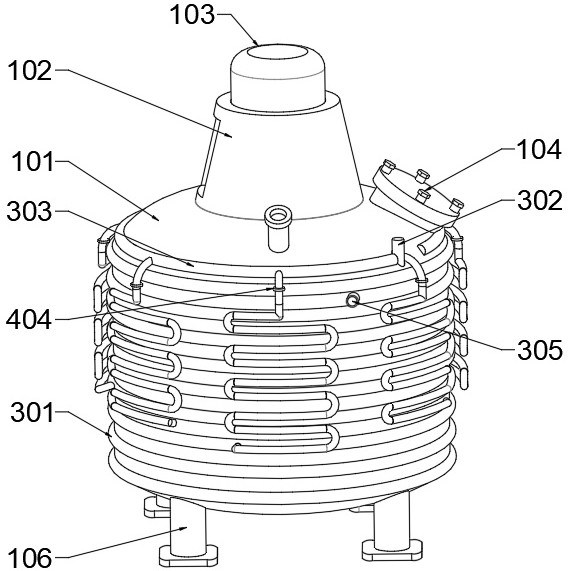

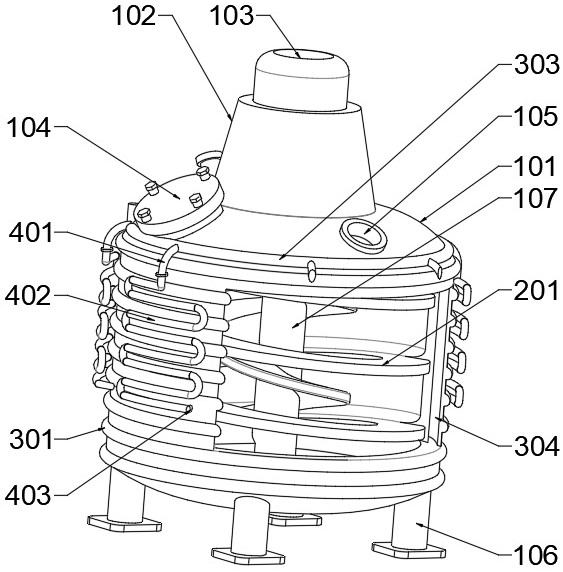

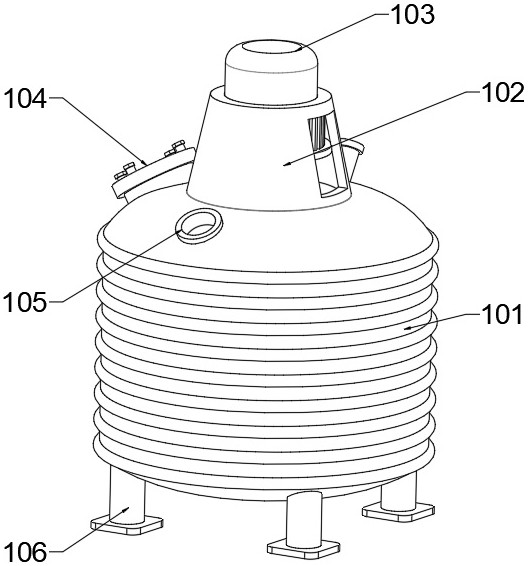

[0032]A nitration reactor for producing p-nitrotoluene from toluene, including a reaction kettle 101, a motor support body 102, a motor 103, a feed port 104, an observation window 105, support feet 106, and an auger 107, and the top center of the reaction kettle 101 is installed There is a motor support body 102, a motor 103 is installed in the motor support body 102, a feed inlet 104 is arranged on the top edge of the reactor 101, an observation window 105 is arranged on one side of the feed inlet 104, and a support foot 106 is installed at the bottom of the reactor 101 The inside of the reactor 101 is provided with an auger 107, and the motor 103 provides rotational power for the auger 107. The inner wall of the reactor 101 is equipped with an agitation strengthening assembly, which can improve the uniformity of the auger 107 for stirring the reactants and improve the nitrification. Reaction efficiency, the agitation strengthening component includes a spiral heat exchange pla...

Embodiment 2

[0050] A nitration reactor for producing p-nitrotoluene from toluene, including a reaction kettle 101, a motor support body 102, a motor 103, a feed port 104, an observation window 105, support feet 106, and an auger 107, and the top center of the reaction kettle 101 is installed There is a motor support body 102, a motor 103 is installed in the motor support body 102, a feed inlet 104 is arranged on the top edge of the reactor 101, an observation window 105 is arranged on one side of the feed inlet 104, and a support foot 106 is installed at the bottom of the reactor 101 The inside of the reactor 101 is provided with an auger 107, and the motor 103 provides rotational power for the auger 107. The inner wall of the reactor 101 is equipped with an agitation strengthening assembly, which can improve the uniformity of the auger 107 for stirring the reactants and improve the nitrification. Reaction efficiency, the agitation strengthening component includes a spiral heat exchange pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com