Molten iron transferring system

A technology of molten iron and transfer vehicles, which is applied in the configuration of indicating equipment/measuring equipment, casting molten material containers, manufacturing tools, etc., and can solve problems such as low production efficiency, cost, and hidden dangers in production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

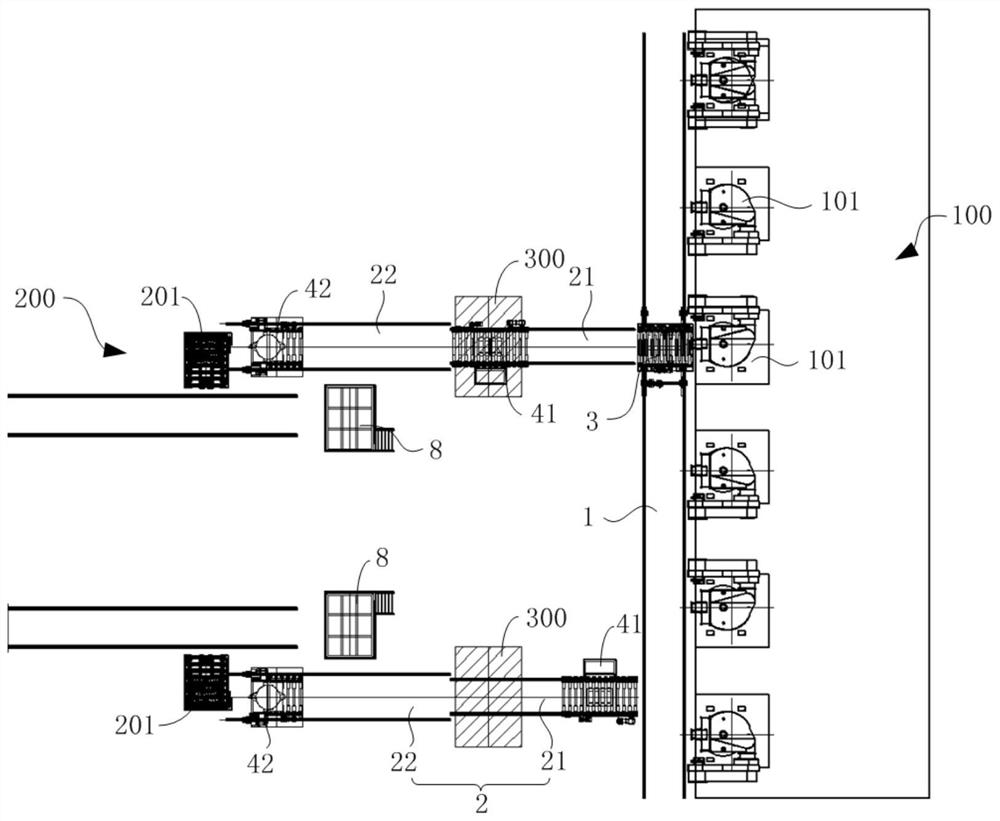

[0038] The embodiment of the present invention provides a molten iron transfer system, such as figure 1 As shown, the molten iron transfer system includes a smelting area 100, a pouring area 200 and a transfer mechanism, wherein the transfer mechanism is arranged between the smelting area 100 and the pouring area 200, and the transfer mechanism can transfer the molten iron produced by each smelting furnace 101 of the smelting area 100 The molten iron is transferred to the pouring area 200 and poured into the pouring machine 201 .

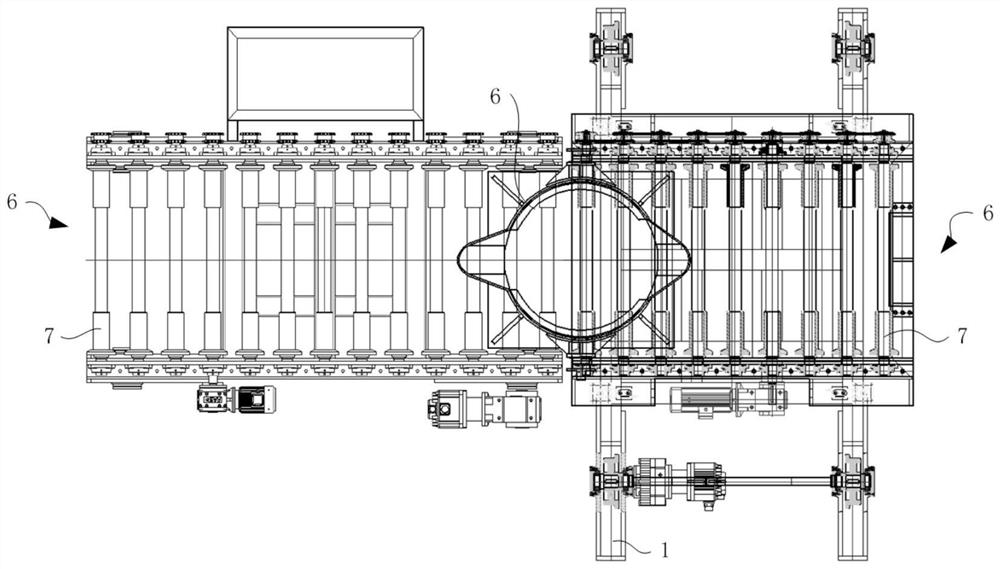

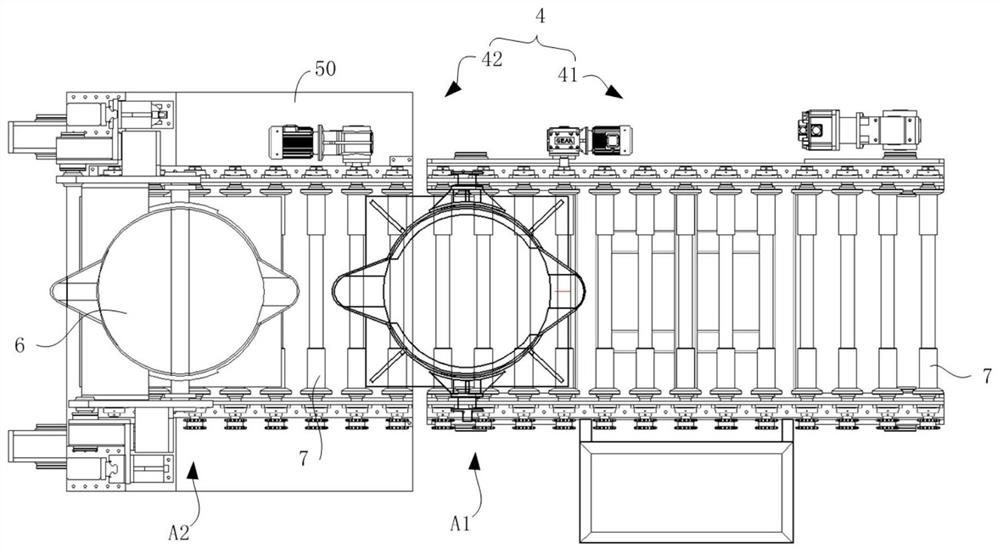

[0039] Specifically, such as figure 1 As shown, the transfer mechanism includes a transfer bag 6, a first track 1, a second track 2, a first transfer car 3 and a second transfer car 4, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com