Injection mold for ultra-precision device processing

An injection mold, ultra-precision technology, applied in the field of ultra-precision machinery and equipment, can solve problems such as surface cracks in injection molded parts, deformation of injection molded parts, and reduction of product injection production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

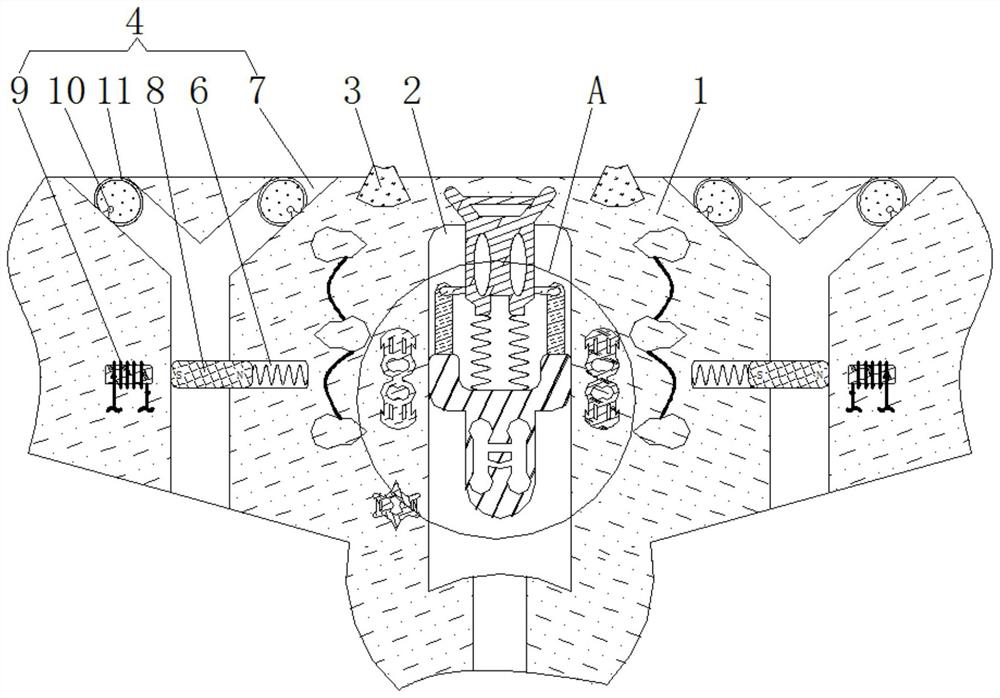

[0025] see figure 1 and image 3 , an injection mold for ultra-precision device processing, including a housing 1, the inner wall of the housing 1 is provided with a chute 2, the inner wall of the housing 1 is fixedly connected with a buzzer 3, and the inner wall of the housing 1 is movably connected with a Decompression mechanism 4;

[0026] The decompression mechanism 4 includes an air outlet groove 7. The inner wall of the housing 1 is provided with a card slot 6. The inner wall of the card slot 6 is elastically connected with a magnetic plate 8. The structure of the magnetic plate 8 is a cuboid structure. The magnetic plate 8 and the inner wall of the card slot 6 Close fit, the number of magnetic plates 8 is the same as the number of winding spiral tubes 9, the magnetic plate 8 plays a closed role, the inner wall of the housing 1 and the outer side close to the magnetic plate 8 are fixedly connected with the winding spiral tubes 9, and the air outlet The inner wall of th...

Embodiment 2

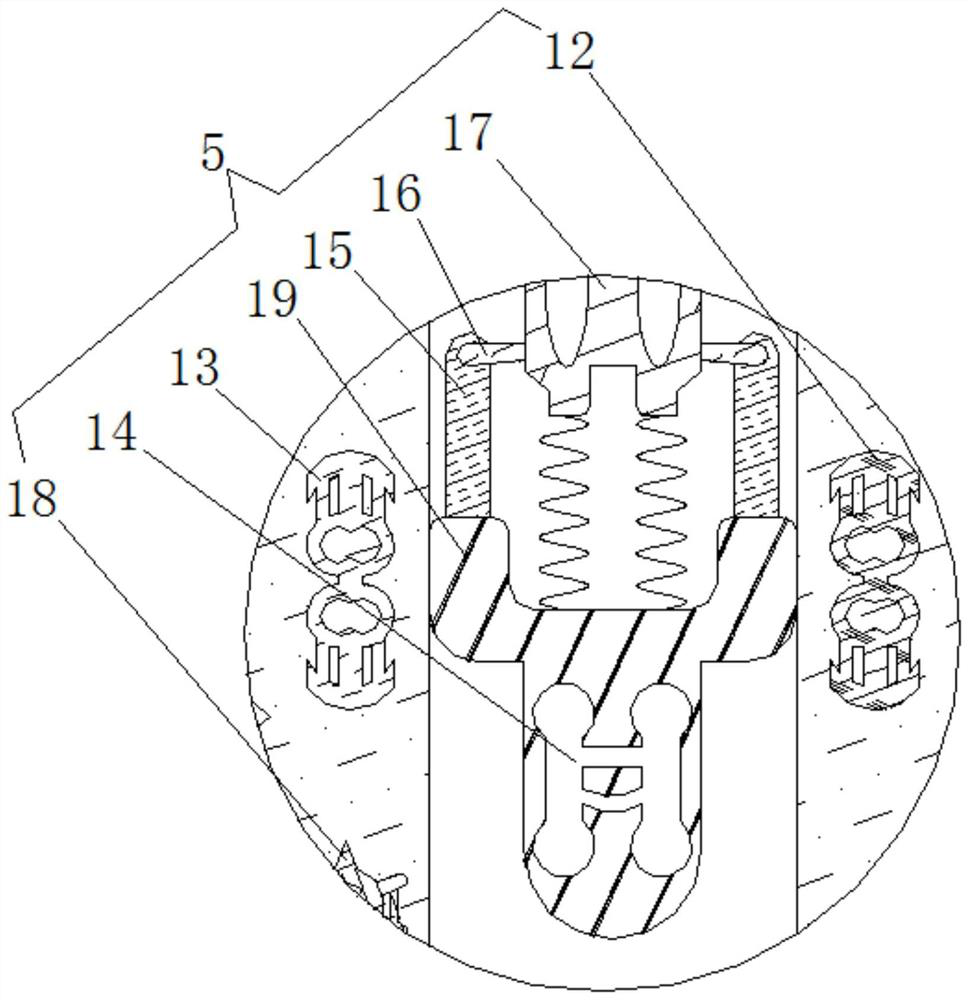

[0028] see Figure 1-4 , an injection mold for ultra-precision device processing, including a housing 1, the inner wall of the housing 1 is provided with a chute 2, the inner wall of the housing 1 is fixedly connected with a buzzer 3, and the inner wall of the housing 1 is movably connected with a A decompression mechanism 4, the inner wall of the housing 1 is movably connected with a trigger mechanism 5;

[0029] The trigger mechanism 5 includes a sliding rheostat 17, the bottom of the sliding rheostat 17 is elastically connected with a slide block 19, the outside of the slide block 19 is fixedly connected with a connecting rod 15, and the inside of the connecting rod 15 is fixedly connected with a metal sheet 16, and the number of the metal sheets 16 is Twice the number of sliding rheostats 17, the metal sheet 16 is electrically connected to the sliding rheostat 17, the sliding rheostat 17 is electrically connected to the piezoresistor 18, the metal sheet 16 plays the role o...

Embodiment 3

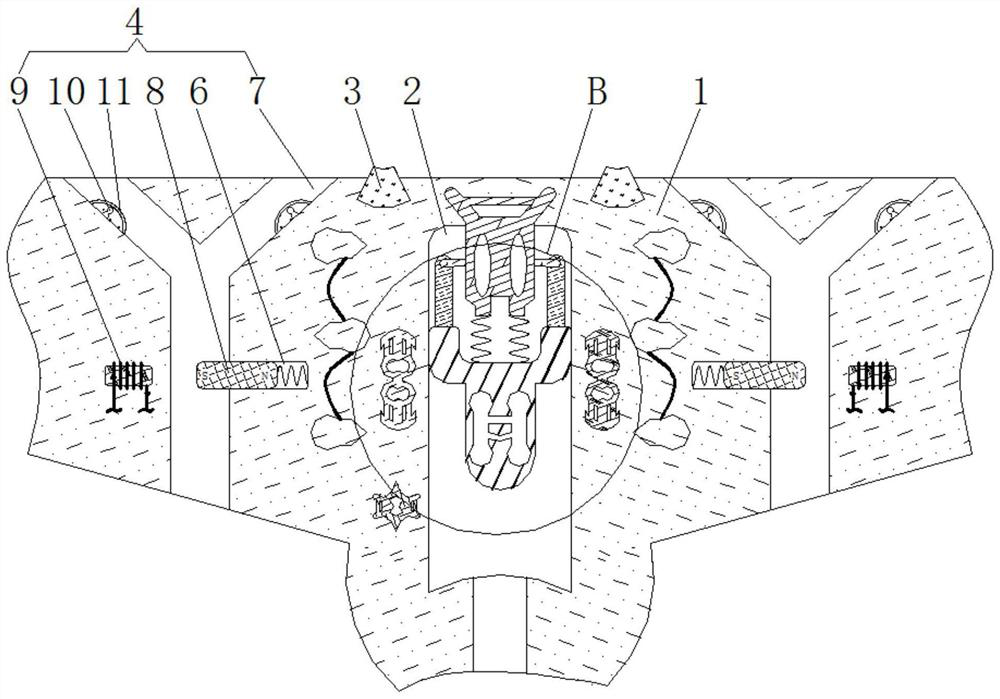

[0031] see Figure 1-4 , an injection mold for ultra-precision device processing, including a housing 1, the inner wall of the housing 1 is provided with a chute 2, the inner wall of the housing 1 is fixedly connected with a buzzer 3, and the inner wall of the housing 1 is movably connected with a Decompression mechanism 4;

[0032] The decompression mechanism 4 includes an air outlet groove 7. The inner wall of the housing 1 is provided with a card slot 6. The inner wall of the card slot 6 is elastically connected with a magnetic plate 8. The structure of the magnetic plate 8 is a cuboid structure. The magnetic plate 8 and the inner wall of the card slot 6 Close fit, the number of magnetic plates 8 is the same as the number of winding spiral tubes 9, the magnetic plate 8 plays a closed role, the inner wall of the housing 1 and the outer side close to the magnetic plate 8 are fixedly connected with the winding spiral tubes 9, and the air outlet The inner wall of the groove 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com