Wind power blade support bolt packaging production line

A packaging production line and support bolt technology, applied in packaging and other directions, can solve the problems of increased labor costs, low packaging efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

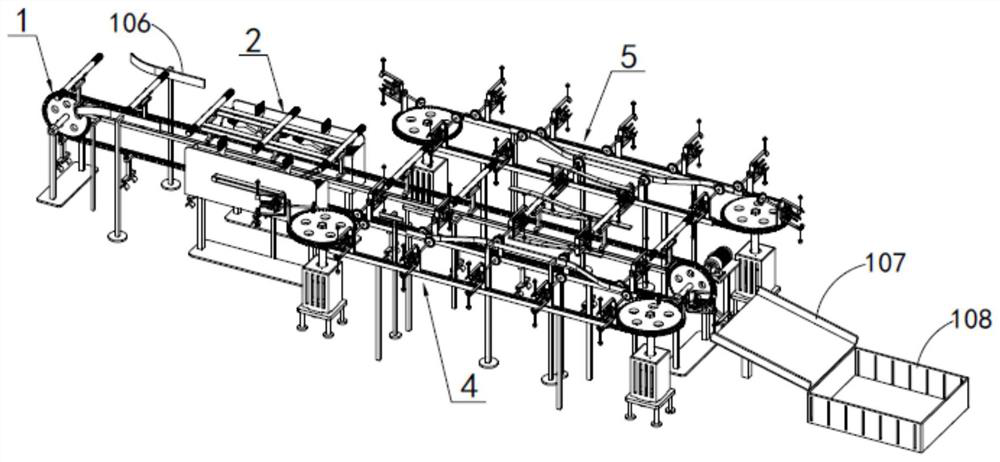

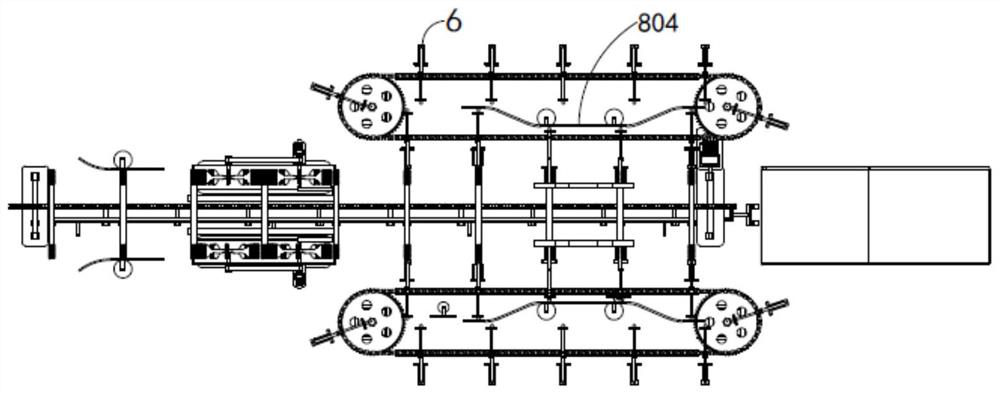

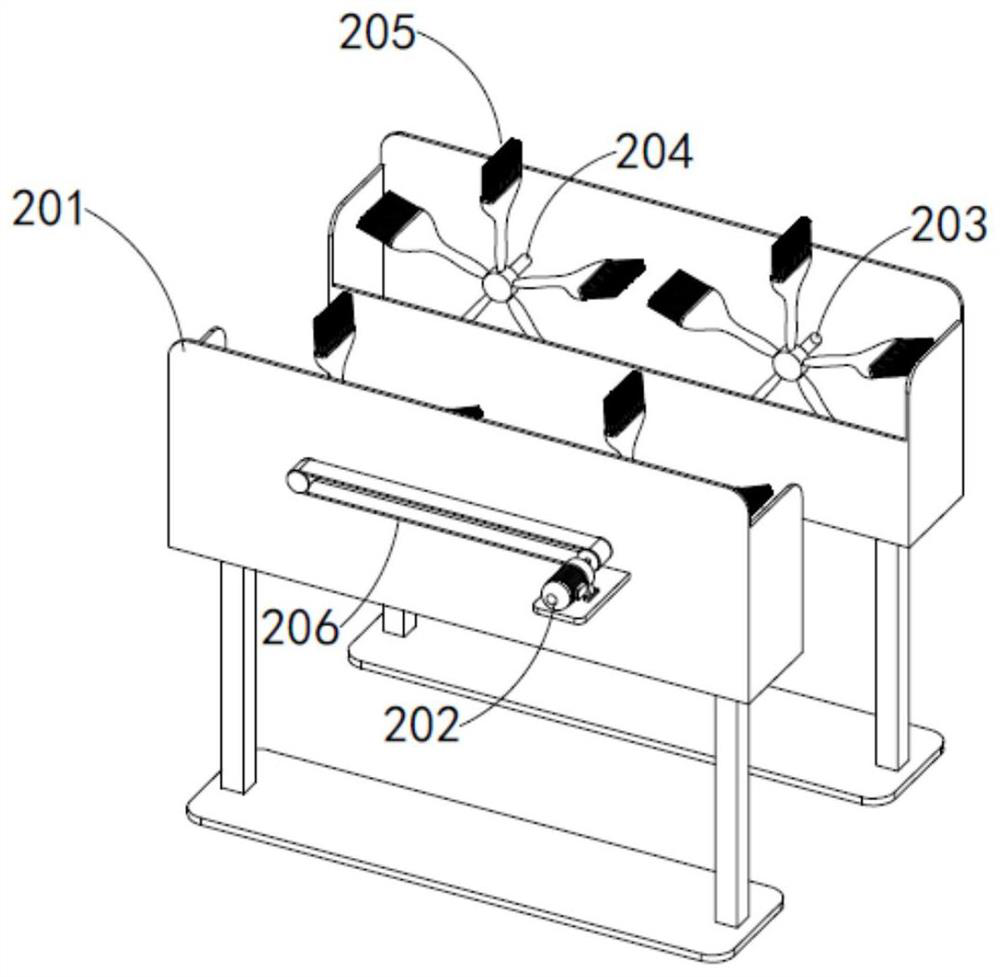

[0042] Such as Figure 1 to Figure 17 As shown, a wind power blade bracket bolt packaging production line includes a first rotary mechanism 1, and the first rotary mechanism 1 is provided with several equidistant bearing seats 101, and the bearing seats 101 are used to carry support bolts 102. The moving path of the bolt 102 is provided with a matching oiling assembly 2, and the oiling assembly is also provided with a rolling assembly 3 for linkage and cooperation. The rolling assembly 3 is used to drive the passing bolt 102 to rotate and cooperate with the oiling assembly. The oil assembly 2 oils the thread 103 at both ends of the bolt 102, and the two sides of the first rotary mechanism 1 are also provided with a second rotary mechanism 4 and a third rotary mechanism 5 that match, and the second rotary mechanism 4 and the third rotary mechanism 5 are provided with several equidistant packaging mechanisms 6, the packaging mechanism 6 includes an expansion assembly 7, a side p...

Embodiment 2

[0055] Such as figure 1 As shown, the parts that are the same as or corresponding to those in Embodiment 1 adopt the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences between Embodiment 1 and Embodiment 1 are described below; the differences between Embodiment 2 and Embodiment 1 The difference is that a matching output slide 107 is provided under the other end of the first turning mechanism 1 , and a finished product collection box 108 is provided on one side of the output slide 107 .

[0056] The working process is as follows:

[0057] The operator puts the bolt 102 on the bearing seat 101, and the bolt 102 moves under the drive of the first rotary mechanism 1, and the bolt 102 is limited and adjusted when passing through the eight-shaped limit baffle 106, and then the bolt 102 moves to the oiled position. At the component 2 and the rolling component 3, the rolling component 3 rotates synchronously under the linkage of the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com