Super slump concrete admixture and preparation method thereof and a kind of super slump concrete

A concrete admixture and admixture technology, which is applied in the field of concrete admixtures, can solve the problems of increased slump loss of commercial concrete, inability to play an effective slump-preserving effect, and increased viscosity of commercial concrete, so as to improve the slump-preserving effect. , good workability, good slump retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

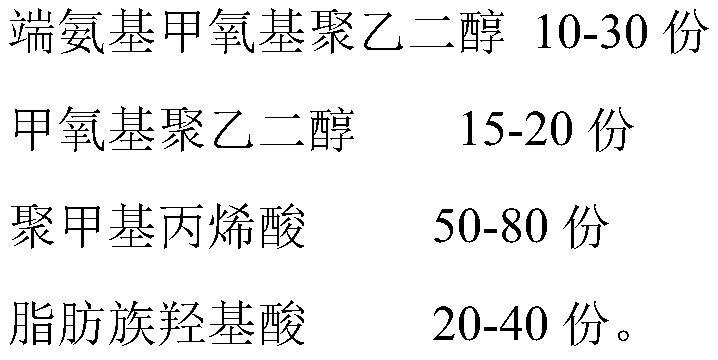

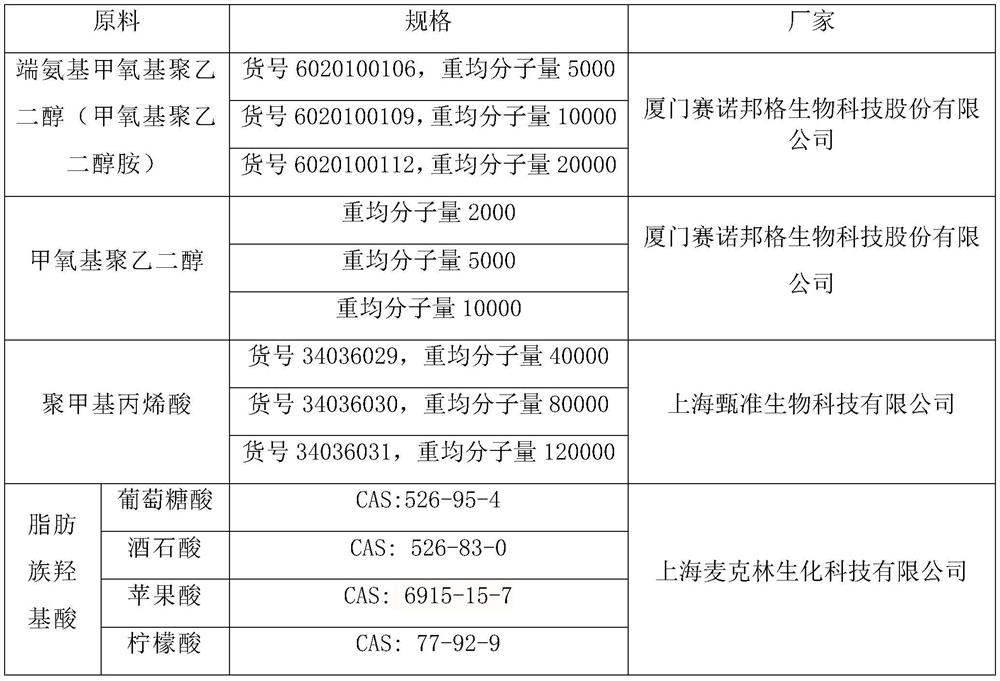

Method used

Image

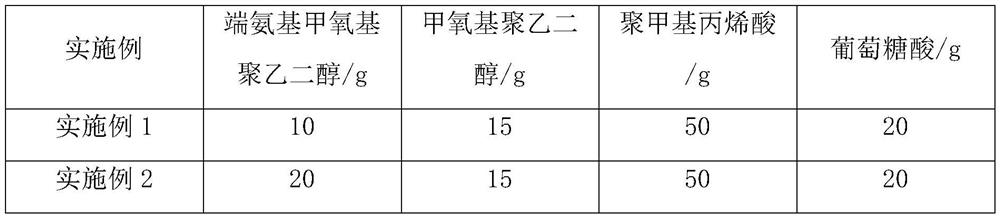

Examples

Embodiment 10-11

[0044] A super slump-preserving concrete admixture, the difference from Example 9 is that the weight-average molecular weight of the terminal aminomethoxy polyethylene glycol is different, and the weight-average molecular weight of the terminal aminomethoxy polyethylene glycol used in Example 10 is is 10,000, and the weight-average molecular weight of the aminomethoxy-terminated polyethylene glycol used in Example 11 is 20,000.

Embodiment 12-13

[0046] A super-slump-preserving concrete admixture is different from Example 11 in that the weight-average molecular weight of methoxy polyethylene glycol is different. The weight-average molecular weight of methoxy polyethylene glycol used in Example 12 is 5,000. The methoxy polyethylene glycol used in Example 13 had a weight average molecular weight of 10,000.

Embodiment 14-15

[0048]A super-slump-preserving concrete admixture, the difference from Example 13 is that the weight-average molecular weight of polymethacrylic acid is different. The weight-average molecular weight of polymethacrylic acid used in The weight-average molecular weight of methacrylic acid was 120,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com