Prepreg resin composition, prepreg resin system, fiber reinforced resin-based prepreg and preparation method and application thereof

A technology of fiber-reinforced resin and pre-impregnated resin, which is applied in the field of composite materials and can solve problems such as failure to popularize and apply, poor product stability, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Some embodiments of the present invention also provide a method for preparing a fiber-reinforced resin-based prepreg, which includes: preparing a resin film from the above-mentioned prepreg resin system at 20-35°C and mixing it with the reinforcement while forming the film The fibers are impregnated.

[0038] By making the entire process of preparing fiber-reinforced resin-based prepregs be carried out at room temperature, it is convenient and simple, without heating, and greatly saves energy consumption. At the same time, various functions can be endowed to prepregs during the preparation process. Production provides a more cost-effective solution.

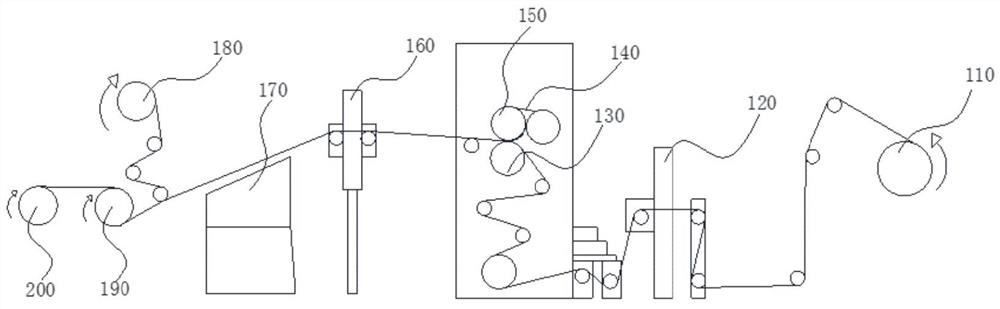

[0039] Specifically, the attached figure 1 , in some implementations of the present invention, the above-mentioned prepreg resin system is passed figure 1 The equipment is impregnated at room temperature, and then placed at 20-35°C for at least 1 day, preferably 1-2 days. figure 1 The basic operation process of the equi...

Embodiment 1

[0051] This embodiment provides a fiber-reinforced resin-based prepreg, the fiber-reinforced resin-based prepreg consists of two parts, one of which is HFW200T-A3-2 / 2-1000 (Jiangsu Hengshen Co., Ltd.) Carbon fiber fabric, which accounts for 58% of the total weight of the prepreg, and the other part is a liquid prepreg resin system, which accounts for 42% of the total weight of the prepreg. Among them, the prepreg resin system includes a resin matrix, a chain extender and a latent curing agent. The permanent curing agent is dicyandiamide (Air Chemicals, USA) and urea accelerator UR500 (Azken, Germany).

[0052] The amount of polyether amine used is 25% of the product of the epoxy value of the epoxy resin used and the active hydrogen equivalent, and the amount of dicyandiamide and urea accelerator is 4% of the total weight of the prepreg resin system used.

[0053] The preparation process of the fiber-reinforced resin-based prepreg specifically includes:

[0054] 1) The resin ...

Embodiment 2

[0076] This embodiment provides a fiber-reinforced resin-based prepreg, which consists of two parts, one of which is HFW200T-A3-2 / 2-1000 (Jiangsu Hengshen Co., Ltd.) specification The carbon fiber fabric accounts for 58% of the total weight of the prepreg, and the other part is the liquid prepreg resin system, which accounts for 42% of the total weight of the prepreg. Among them, the prepreg resin system includes a resin matrix, a chain extender and a latent curing agent. The resin matrix is a low-viscosity vinyl modified epoxy resin Hetron 922 (Ashland, USA), and the chain extender is a modified alicyclic primary amine. The permanent dicyandiamide (Ningxia Hengkang), the latent curing agent is tert-butyl perbenzoate (Shandong Leon).

[0077] The amount of dicyandiamide modified by cycloaliphatic primary amine is 20% of the product of epoxy resin epoxy value and active hydrogen equivalent, and the amount of tert-butyl perbenzoate is 1% of the total weight of the prepreg resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com