Method for decolorizing peony seed oil

A decolorization technology of peony seed oil, applied in the direction of fat oil/fat refining, fat production, etc., to achieve the effects of short decolorization time, reduced refining loss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

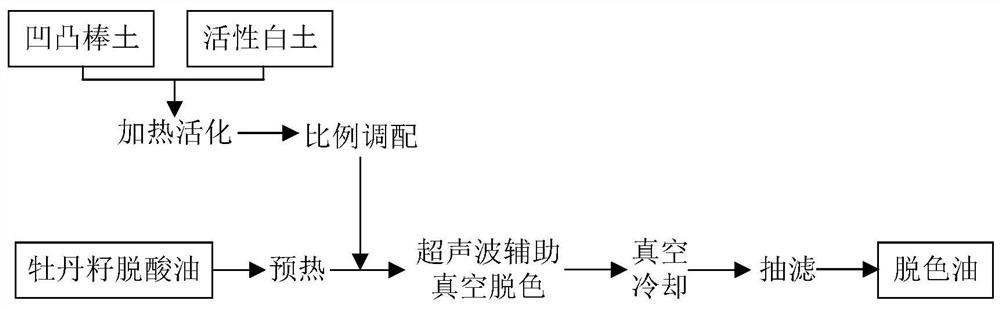

Method used

Image

Examples

Embodiment 1

[0030] Follow the following steps successively to decolorize the peony seed oil after deacidification:

[0031] (1) Weigh 500g of deacidified peony seed oil and preheat at 90°C for 30min;

[0032] (2) Put the standby activated clay and attapulgite in a drying oven at 105°C, after activating for 2.0 hours, take them out and place them in a desiccator for later use;

[0033] (3) Add 4% composite decolorizing agent to the preheated peony seed oil, the addition ratio of activated clay and attapulgite in the composite decolorizer is 1:1, that is, add 10g activated clay and 10g attapulgite; control the decolorization temperature The temperature is 85°C, the decolorization vacuum degree is between -0.095~-0.090MPa, the ultrasonic auxiliary power is 40kHz, the mechanical stirring rate is 120r / min, and the decolorization time is 25min;

[0034] (4) After the decolorization treatment of peony seed oil is completed, it is cooled to about 60° C. under a vacuum degree of -0.095 to -0.090 ...

Embodiment 2

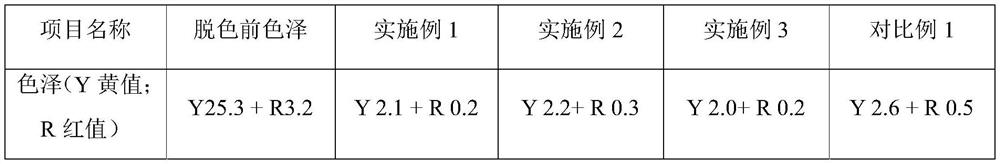

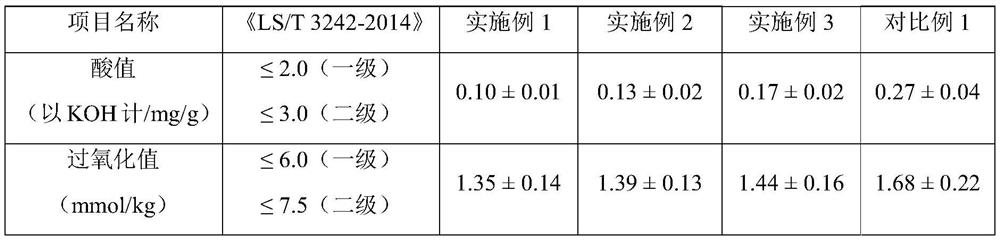

[0037] Adjust the addition ratio of activated clay and attapulgite in Example 1 to 2:3, that is, add 8g activated clay and 12g attapulgite, and the other operating steps and parameters are the same as in Example 1, and the peony seed oil is decolorized operation, the decolorized peony seed oil is prepared.

[0038] It was found that the decolorized peony seed oil was light yellow or golden yellow, and the oil was clear and transparent. It was further detected by the Lovibond colorimeter that the color of the oil was significantly improved, indicating that the decolorization effect of the process was good. By analyzing the content of trace active ingredients (including vitamin E and phytosterols) and neutral oil content in peony seed oil before and after decolorization, and comparing it with conventional activated clay decolorization of peony seed oil, the results show that the above decolorization method is also effective Reduce the loss of trace active ingredient content and ...

Embodiment 3

[0040] The dosage of the composite decolorizing agent in Example 1 is adjusted to 3%, the addition ratio of activated clay and attapulgite is adjusted to 2:1, that is, 10g activated clay and 5g attapulgite are added, the decolorization time is adjusted to 30min, and other operations The steps and parameters are the same as in Example 1, and the peony seed oil is decolorized to prepare the decolorized peony seed oil.

[0041] It was found that the decolorized peony seed oil was light yellow or golden yellow, and the oil was clear and transparent. It was further detected by the Lovibond colorimeter that the color of the oil was significantly improved, indicating that the decolorization effect of the process was good. By analyzing the content of trace active ingredients (including vitamin E and phytosterols) and neutral oil content in peony seed oil before and after decolorization, and comparing it with conventional activated clay decolorization of peony seed oil, the results show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com