Method for preparing edible safflower tea oil

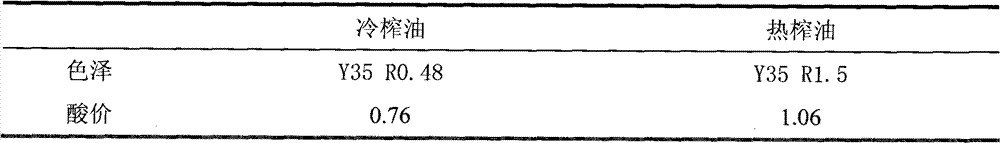

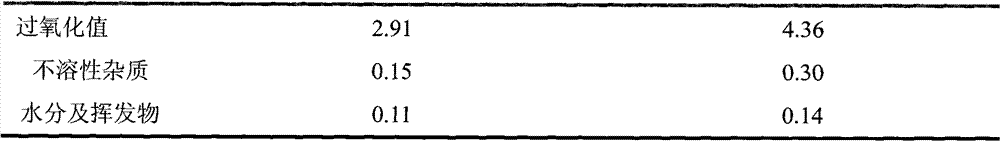

A technology for safflower camellia oil and safflower camellia, which is applied in the production/processing of edible oil/fat, etc., can solve the problems of unfavorable nutritional components and quality of safflower camellia oil, lack of technical solution reports of safflower camellia oil, and quality of crude oil. Insufficient and other problems, to achieve the effect of shortening the production cycle, reducing equipment investment, and light color of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 safflower tea oil

[0028] With (Guangning) safflower camellia seed as raw material, comprise the following steps:

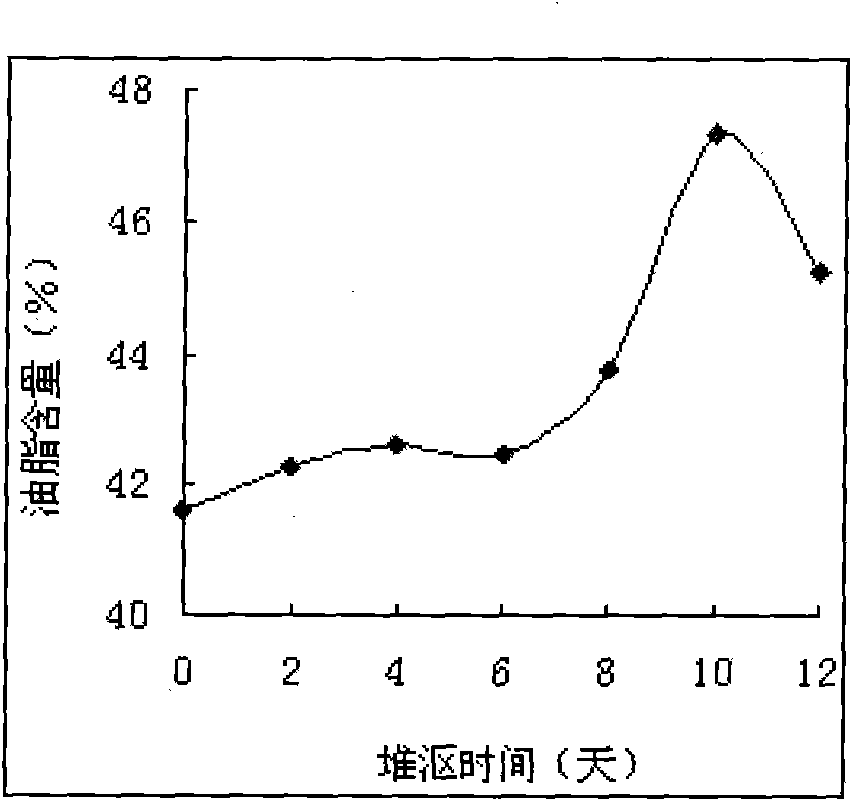

[0029] (1) After the harvested mature safflower camellia fruit is stacked and retting at room temperature for 10 days to make the oil content higher, the shell of the camellia oleifera fruit is removed and the tea seeds are taken out, and the tea seeds are dried with hot air at 40°C to make the water content reach a relatively safe level Water content below 9.5%;

[0030] (2) The safflower camellia seeds after low-temperature drying are cleaned and destoned, and the camellia seeds are crushed and shelled by using an impact crusher. Add water to 1% of the weight of the pulverized material to obtain a mixture;

[0031] (3) The mixture prepared in the cold pressing extraction step (2), the pressing temperature is about 50°C; crude oil is obtained;

[0032] (4) After the cold-pressed crude oil is filtered, the temperature is...

Embodiment 2

[0033] The preparation of embodiment 2 safflower tea oil

[0034] Using safflower camellia seed as raw material, comprising the following steps:

[0035] (1) After the harvested mature safflower camellia fruit was stacked and retting at room temperature for 5 days to make the oil content higher, the shell of the camellia fruit was removed and the tea seeds were taken out, and the tea seeds were dried with hot air at 50°C to make the water content reach the relative The safe water content is below 9.5%;

[0036] (2) The safflower camellia seeds after low-temperature drying are cleaned and destoned, and the camellia seeds are crushed and shelled by using an impact crusher. The shell content in the kernels is 10%. Add water to 2% of the weight of the pulverized material to obtain a mixture;

[0037] (3) The mixture prepared in the cold pressing extraction step (2), the temperature of entering into the pressing is about 60°C; crude oil is obtained;

[0038] (4) After the cold-p...

Embodiment 3

[0039] The preparation of embodiment 3 safflower tea oil

[0040] Using safflower camellia seed as raw material, comprising the following steps:

[0041] (1) After the harvested mature safflower camellia fruit was stacked and retting at room temperature for 8 days to make the oil content higher, the shell of the camellia oleifera fruit was removed and the tea seeds were taken out, and the tea seeds were dried with hot air at 55°C to make the water content reach the relative The safe water content is below 9.5%;

[0042] (2) The safflower camellia seeds after low-temperature drying are cleaned and destoned, and the camellia seeds are crushed and shelled by using an impact crusher. The shell content in the kernels is 10%. Add water to 3% of the weight of the pulverized material to obtain a mixture;

[0043] (3) The mixture prepared in the cold pressing extraction step (2), the pressing temperature is about 70°C; crude oil is obtained;

[0044] (4) After the cold-pressed crude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com