Pinolenic acid lutein ester enriched pine-seed oil and preparation method thereof

A technology of lutein lutein and pine nut oil, which is applied in the field of pine nut oil rich in lutein lutein pinovenate and its preparation field, can solve the problems of low stability and low activity of lutein, and achieve Simple operation, low reaction temperature, and the effect of overcoming low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

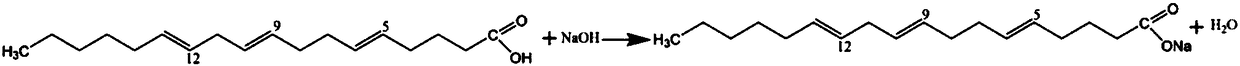

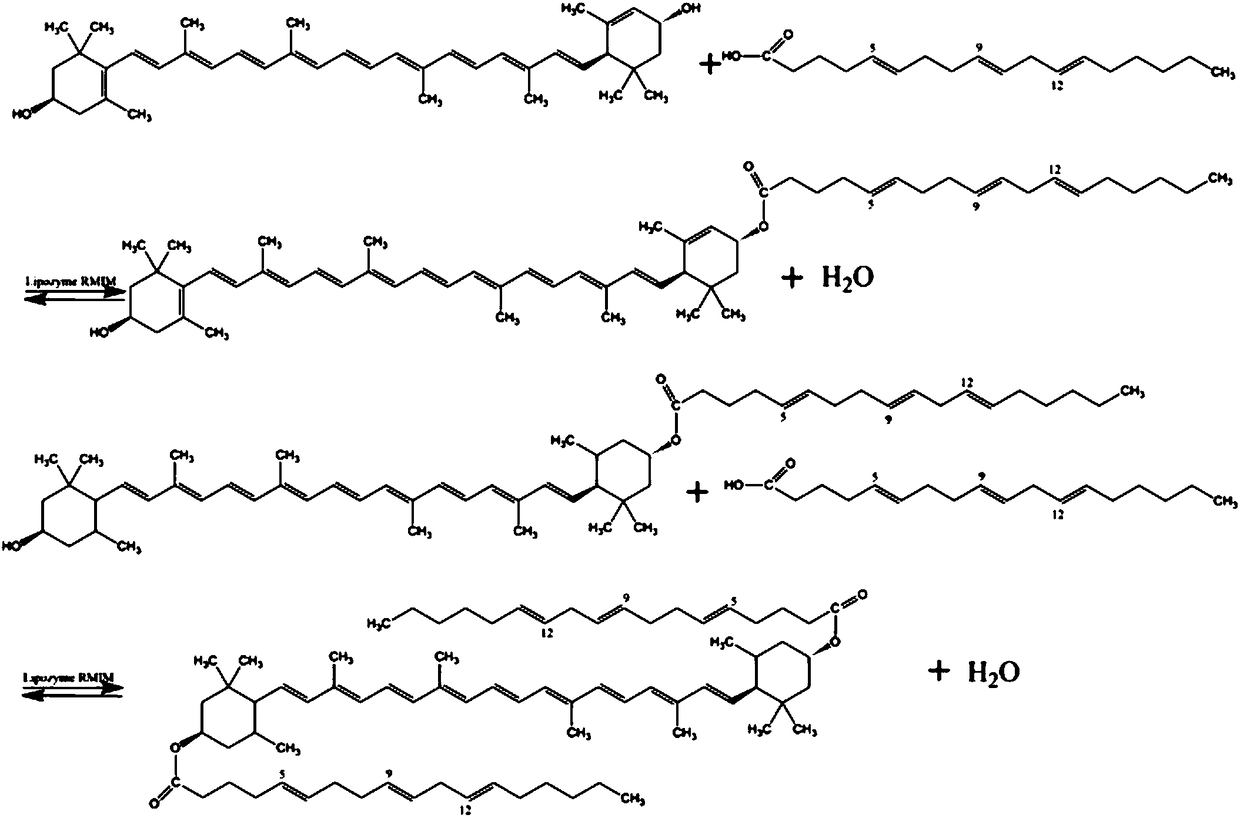

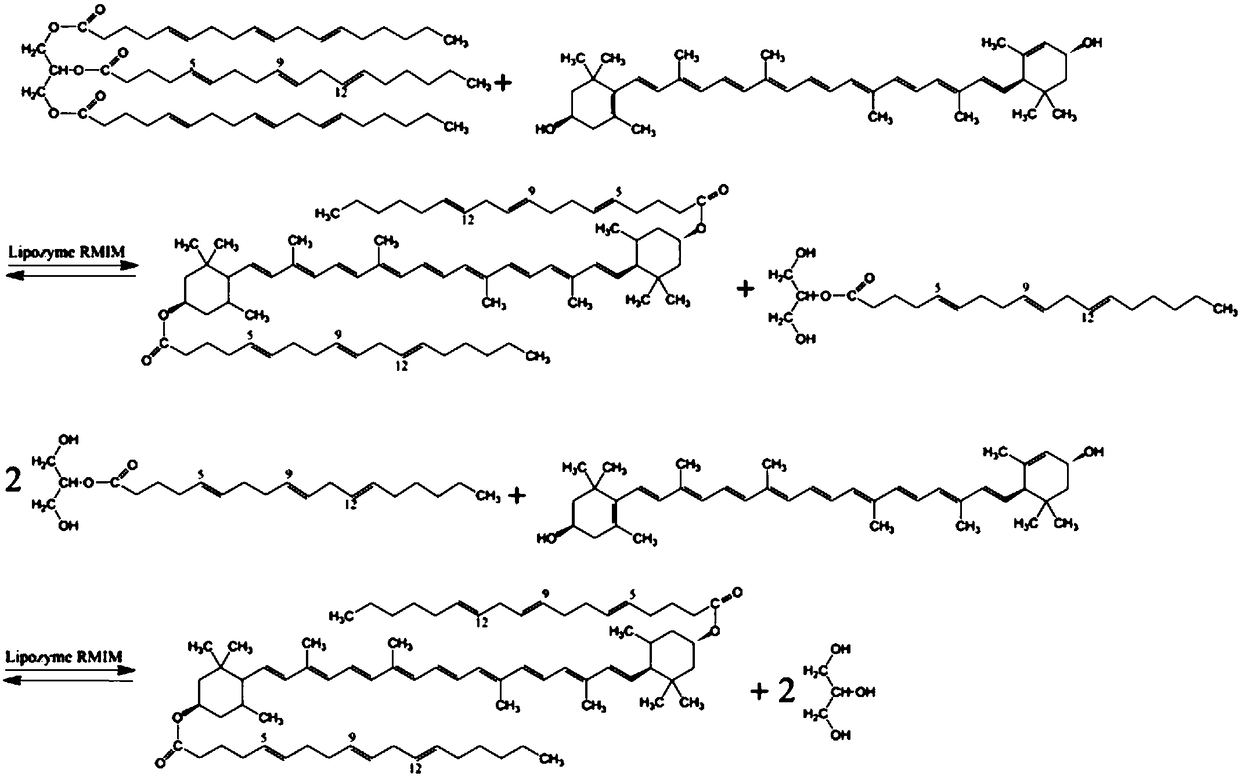

Method used

Image

Examples

Embodiment 1

[0029] (1) Esterification and deacidification of lutein: first, add 3.51KG lutein and 1000L absolute ethanol into the esterification kettle, heat to 30°C, keep stirring for 0.5 hours, cool down to 60°C to obtain a mixture, Next, add 1000KG pine nut crude oil with an acid value of 30KOH mg / g into the mixture of the esterification tank, and at the same time add 351g of immobilized lipase Lipozyme RMIM, keep stirring at 30°C for 4 hours, stop heating, cool down to normal temperature, and the reaction is complete. get the mixture;

[0030] (2) Separation of the mixture: Stir and add 1000 L of saturated saline at a temperature of 65°C to the esterification kettle, let the layers stand for 2 hours, recover the solvent from the lower layer, repeat the same method for washing once, discard the lower layer, turn on the vacuum pump, and heat up to 65°C Dehydrate at ℃ for 2 hours, until the water content is ≤0.1% by sampling, put the dehydrated material into the freezer, turn on the free...

Embodiment 2

[0032] (1) Esterification and deacidification of lutein: First, add 2.1KG lutein and 100L n-hexane into the esterification kettle, heat to 57.5°C, stir and keep the temperature for 1.7 hours, cool down to 60°C to obtain the mixture, and then 1000KG pine nut crude oil with an acid value of 60KOH mg / g was added to the mixture of the esterification kettle, and 105g of immobilized lipase Lipozyme RMIM was added at the same time, kept at 45°C and stirred for 14 hours under normal pressure to stop heating, and anhydrous sodium sulfate was added during the process. After the reaction is complete, the mixture is obtained;

[0033] (2) Separation of the mixture: turn on the vacuum pump, heat up to 75°C and distill for 3 hours to recover n-hexane, put the material in the esterification kettle into the freezer, turn on the freezer and stir to cool the material down to 10°C, start centrifugal filtration, discard the solid, and the filtrate That is, pine nut oil rich in pinolenic acid lute...

Embodiment 3

[0035] (1) Esterification and deacidification of lutein: First, add 2.92KG lutein and 500L acetone into an esterification kettle, heat to 85°C, keep stirring for 3 hours, then cool down to 60°C to obtain a mixture for later use. Next, add 1000KG pine nut crude oil with an acid value of 50KOH mg / g to the mixture of the esterification kettle, and at the same time add 39g of immobilized lipase Lipozyme RMIM, keep stirring at 60°C for 24 hours and stop heating, and add anhydrous sodium sulfate during the reaction , the reaction is completed to obtain the mixture;

[0036] (2) Separation of the mixture: turn on the vacuum pump, heat up to 85°C and distill for 4 hours to recover acetone, put the material in the esterification kettle into the freezer, turn on the freezer to stir the material to cool down to 0°C, start centrifugal filtration, discard the solid, and the filtrate is ready Pine nut oil rich in pinolenic acid lutein ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com