Making method of anthocyanin instant noodles

A production method and anthocyanin technology, which are applied in the field of food processing, can solve the problems of food safety of chemical synthetic agents, the increasing demand for natural antioxidants, etc., and meet the requirements of healthy green food, improved taste and texture, and good smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

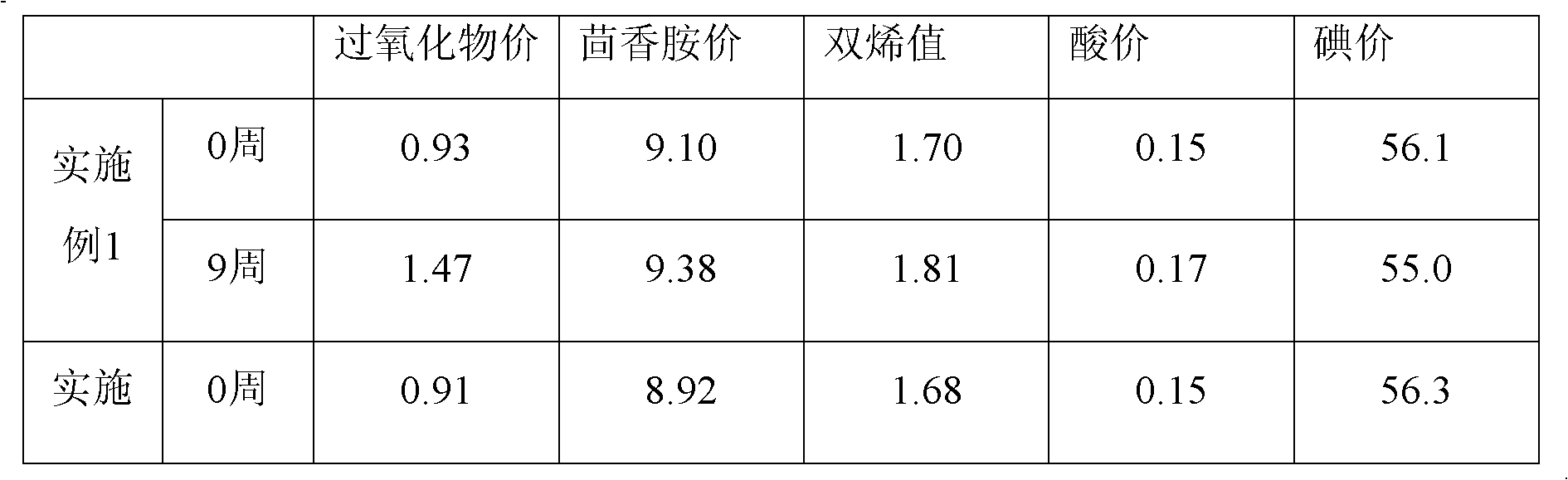

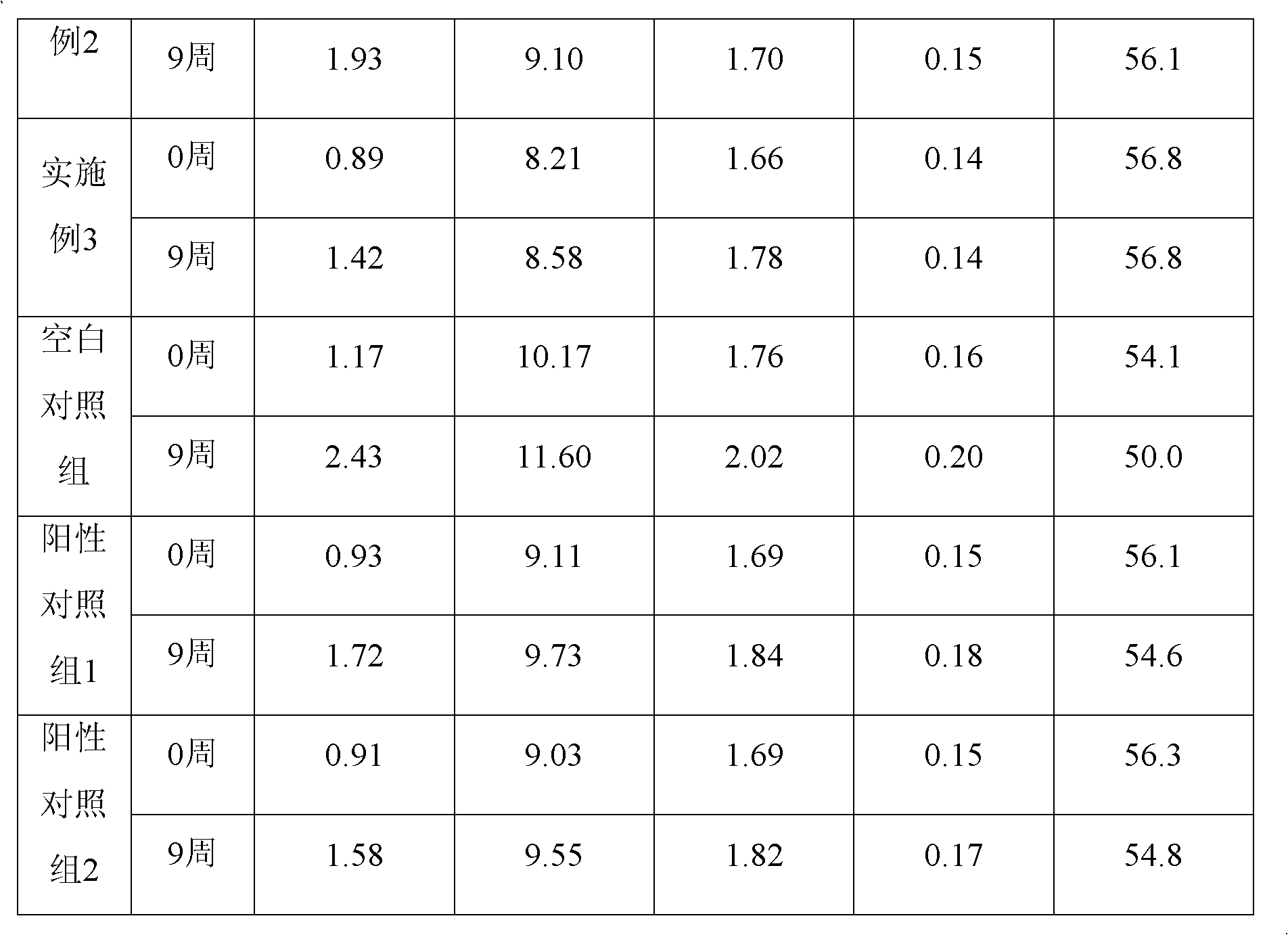

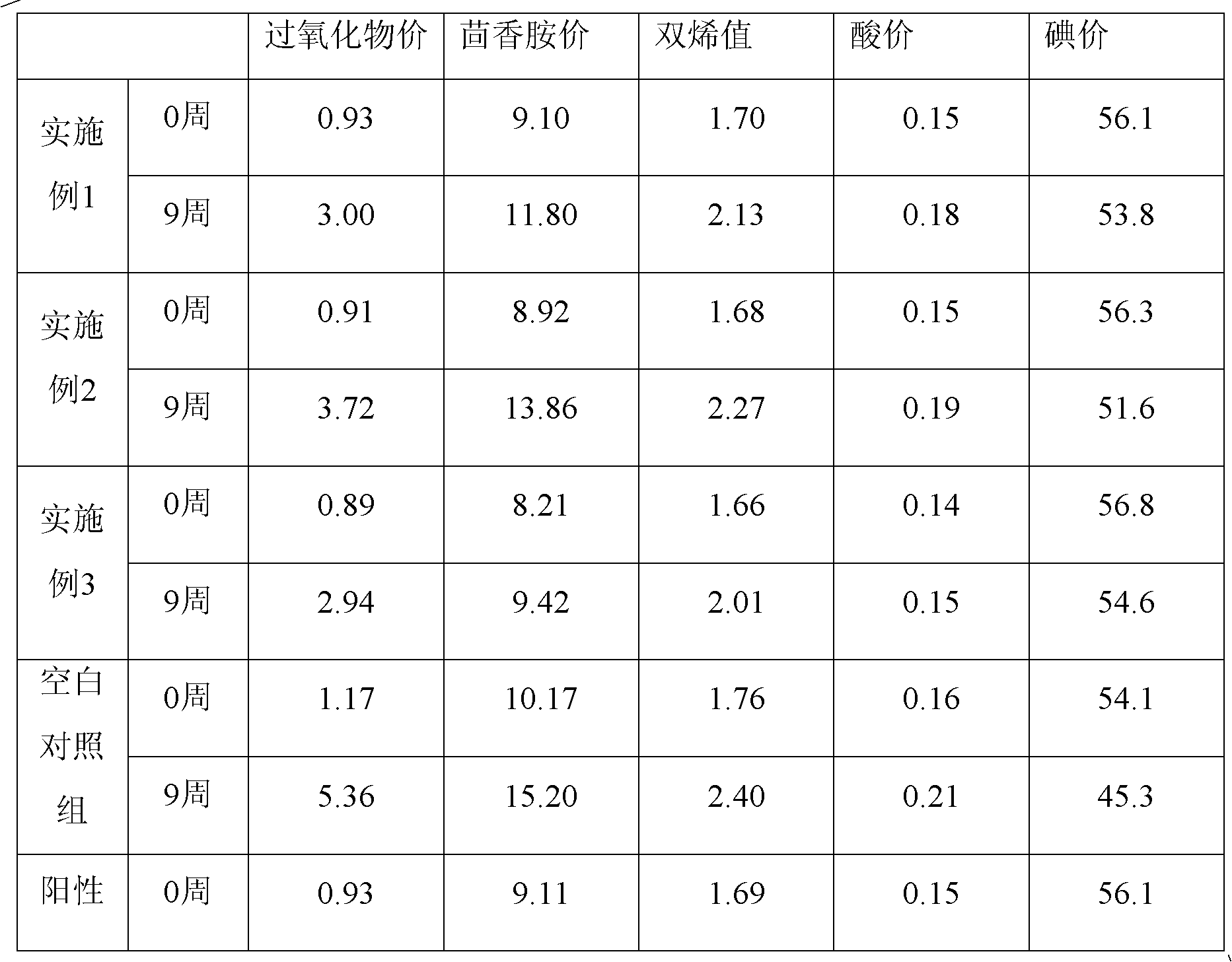

Examples

Embodiment 1

[0026] Embodiment 1, a kind of preparation method of anthocyanin instant noodles, carries out following steps successively:

[0027] 1), preparation of purple corn bract anthocyanin extract:

[0028] The purple corn husk leaves should be removed from the dead leaves, mud, sand, mildew and other parts that should be removed, washed with running water, picked up, and cleaned of impurities, and sent to a baking oven for 2 hours at a temperature of 50-60°C. After drying, pulverize to filament with pulverizer, put into the edible alcohol solution that volume concentration is 70% and carry out lixiviation (material-liquid ratio is 1g / 10ml, promptly, add 10ml volume concentration in the blade after every 1g pulverizes is 70% edible alcohol solution), the extraction temperature is 20° C., and the extraction time is 12 hours. The resulting extraction solution is filtered and concentrated under reduced pressure (10-17 MPa) to obtain the paste-like purple corn bract color Glycoside extr...

Embodiment 2

[0034] Example 2, in step 2) of Example 1, the paste-like purple corn bract anthocyanin extract containing 1g cyanidin 3-O-glucoside was changed to contain 0.5g cyanidin 3 - O-glucoside paste-like purple corn bract anthocyanin extract; ie, cyanidin 3-O-glucoside at 0.01% by weight of flour. All the other are with embodiment 1.

Embodiment 3

[0035] Example 3, in step 2) of Example 1, the paste-like purple corn bract anthocyanin extract containing 1g cyanidin 3-O-glucoside was changed to contain 2g cyanidin 3- Purple maize bract anthocyanin extract in paste form of O-glucoside; ie, cyanidin 3-O-glucoside at 0.04% by weight of flour. All the other are with embodiment 1.

[0036] Blank control group: cancel step 1); cancel the use of anthocyanins in step 2), that is, the instant noodle raw material is made up of flour 5kg, salt 100g, sodium carbonate 7.5g and water 1.5L, and the preparation of step 3) is the same as in Example 1 .

[0037] Positive control group 1: cancel step 1); in step 2), change the paste-like purple corn bract anthocyanin extract containing 1g cyanidin 3-O-glucoside into 1g of natural antioxidant- - vitamin E (α-tocopherol); that is, instant noodle raw material is made up of flour 5kg, salt 100g, sodium carbonate 7.5g, natural antioxidant-vitamin E 1g and water 1.5L, and the preparation of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com