Extraction and separation method of tea polyphenol

A separation method and technology for tea polyphenols, applied in the direction of organic chemistry, etc., can solve the problems of limited application of tea polyphenols, low bioavailability, poor stability, etc., and achieve the effects of great social and economic value, uniform particle size and good gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

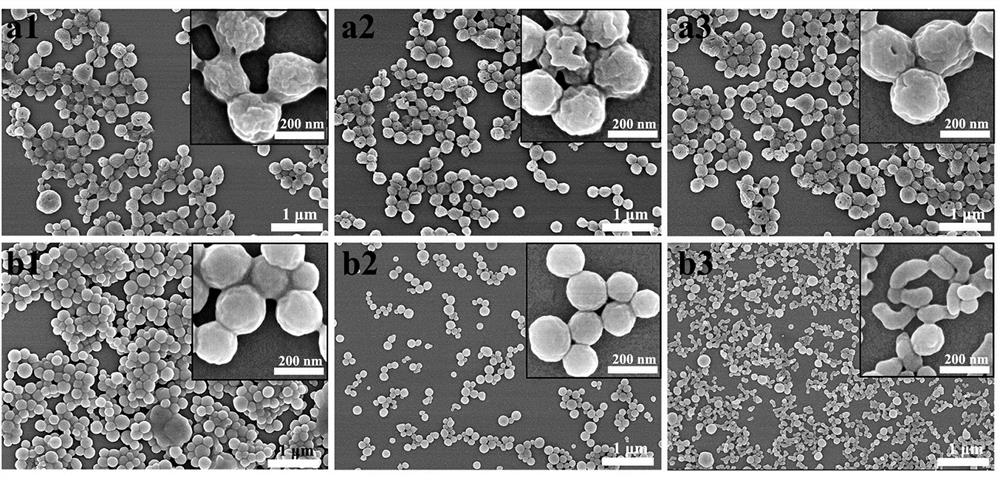

[0024]In the following examples, tea polyphenols, formaldehyde, and amino acids are selected as reaction raw materials, and the particle size control of tea polyphenol micro-nano particles is realized by adjusting the concentration of amino acids. The specific implementation method is as follows: Take 40.0 mL (2.0 mg / mL) of the tea polyphenol solution after adjusting the concentration and add it to a 100 mL round bottom flask, add 30 μL formaldehyde (37%) dropwise, control the reaction temperature at 25°C, and stir for 5-10 After 1 min, 1.0 mL of amino acid solution was added. After the amino acid is added, as the micro-nano particles of tea polyphenols are formed in the aqueous solution, the reaction solution quickly turns from clear and transparent to a milk-like milky white solution. After continuing to stir the solution for 0.5-1 h, the tea polyphenol micro-nanoparticles were collected by centrifugation (8000-10000 rcf×g, 20 min). The tea polyphenol micro-nanoparticles ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com