Mask plate with multi-layer structure

A multi-layer structure and mask technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as sagging, fragile mask structure, shadow, etc., to reduce costs, save materials, Reduce the effect of shadow effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

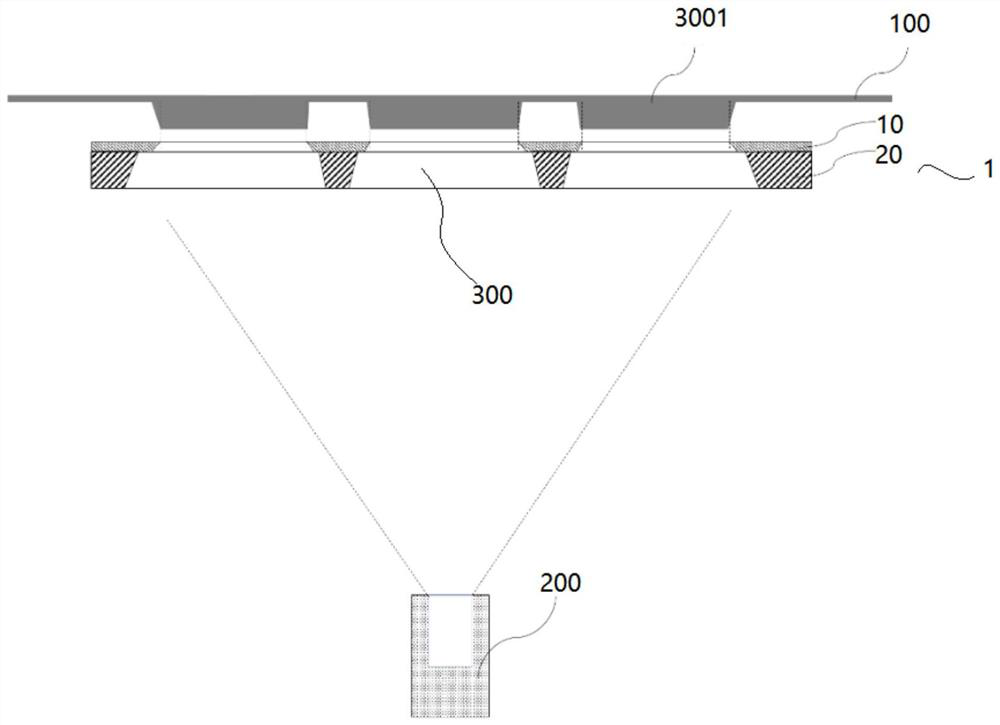

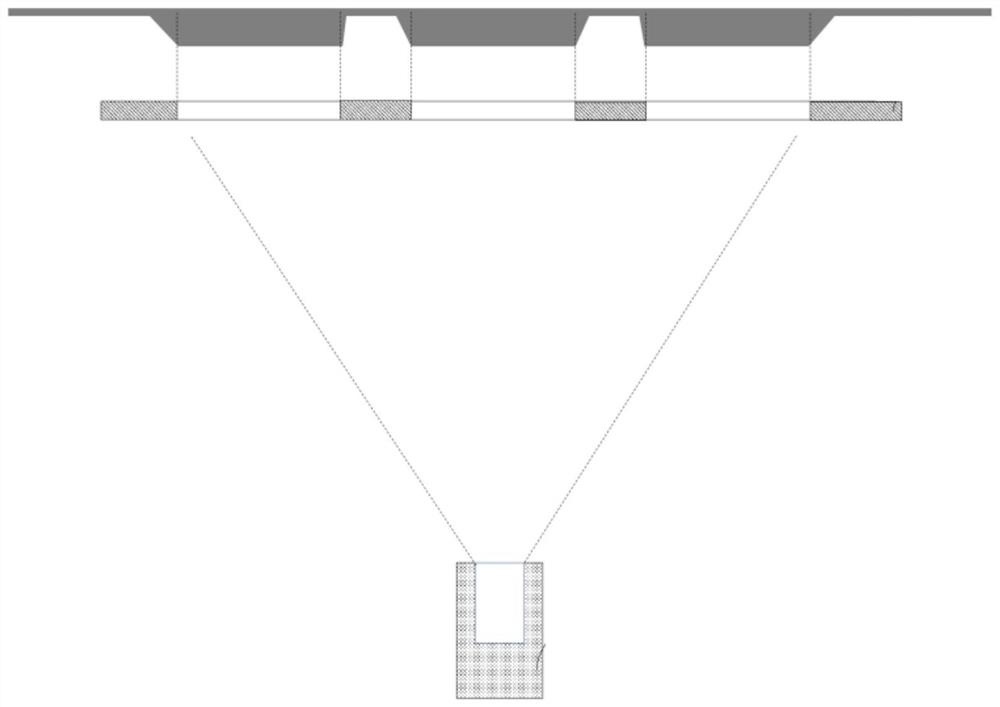

[0027] see figure 1 As shown, a mask plate 1 with a multi-layer structure, the mask plate 1 includes two layers, respectively the first mask layer 10 and the second mask layer 20, the mask plate 1 is provided with a plurality of openings 30. The first mask layer 10 is an extremely thin metal sheet located closest to the substrate 100 , and the opening and pattern of the first mask layer 10 determine the pattern on the silicon substrate 100 to be deposited. Below the first mask layer 10 is a second mask layer 20 . In order to solve the shadow area problem, the opening of the second mask layer 20 is larger than the opening of the first mask layer 10, so that in the process of depositing the organic luminescent material, since the cross section of the first mask layer 10 closest to the substrate 100 is smaller than The cross-section of the second mask layer 20 greatly reduces shadows deposited on the substrate 100 . With such a structure, the second mask layer 20 can be made ...

Embodiment 2

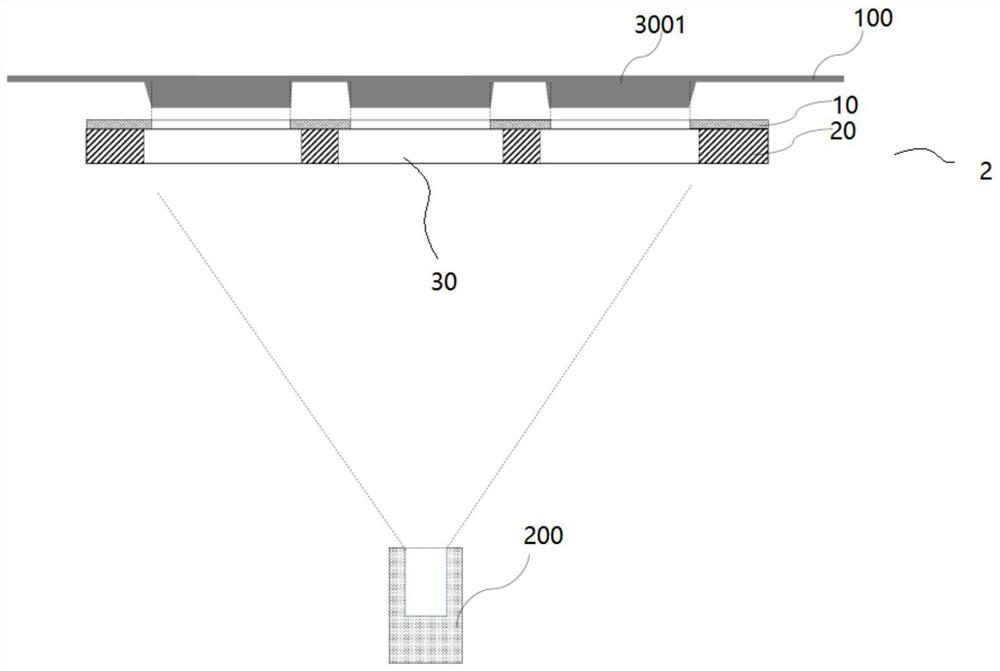

[0031] see figure 2 As shown, a mask plate 2 with a multi-layer structure, the opening cross section of the second mask layer 20 and the opening cross section of the first mask layer 10 form a stepped shape, and the rest is the same as that of Embodiment 1. This kind of structure makes the evaporation material of the organic light-emitting material have a greater flux to reach the substrate without causing waste of materials. At the same time, because it is closer to the deposited silicon substrate 100, the shadow area of the sub-pixel 3001' being deposited will be reduced.

[0032] The beneficial effects that the present invention has are:

[0033] (1) The mask plate of the present invention adopts the design that the entrance of the opening is larger than the exit, which can effectively reduce the shadow effect of the evaporation material;

[0034] (2) The second mask layer can be made thicker due to the opening design of the mask plate, which can effectively support th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com