Intelligent evaporation coating method

An evaporative coating, intelligent technology, applied in the direction of vacuum evaporative coating, sputtering coating, ion implantation coating, etc., can solve the problems that can not meet the needs of use, unfavorable product development and development of emerging thin film industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the present invention, not to limit the present invention.

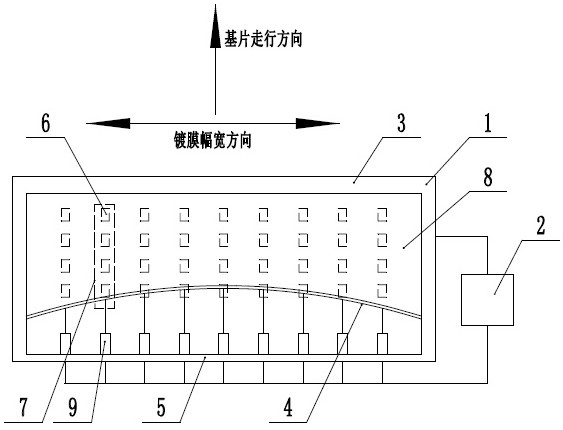

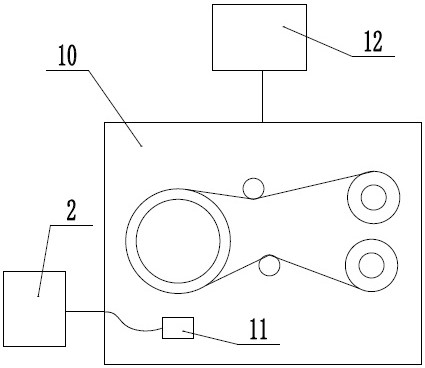

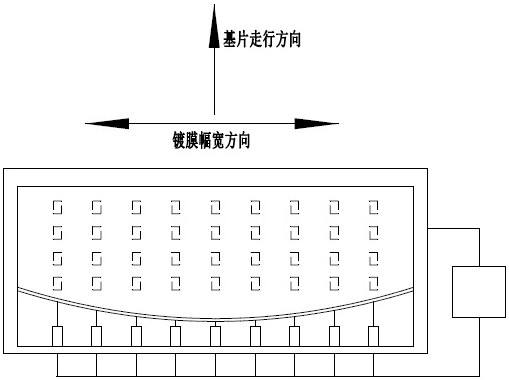

[0047] figure 1 It is a schematic top view of an embodiment of the evaporation source involved in the present invention. Such as figure 1 As shown, the evaporation source mainly includes an evaporation boat 1, a temperature sensing array and a flexible boundary driving system. The evaporation boat 1 includes a frame and a bottom, and the frame includes a fixed frame 3, a flexible frame 4 and a supporting frame 5; the flexible frame 4 is arranged on the side of the evaporation boat parallel to the width direction of the coating, and the fixed frame is arranged on the rest of the evaporation boat. three sides. The temperature sensing array is mainly composed of a plurality of tempera...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap