Fabricated concrete pavement provided with tenons and construction method

A concrete pavement, prefabricated technology, applied to the coagulation pavement paved on site, the pavement paved with prefabricated blocks, roads, etc., can solve the problems of unfavorable plate combination and load transfer, speeding up the construction progress, pavement diseases, etc. Achieve the effect of reducing pavement structural diseases, good sealing effect and preventing rainwater infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

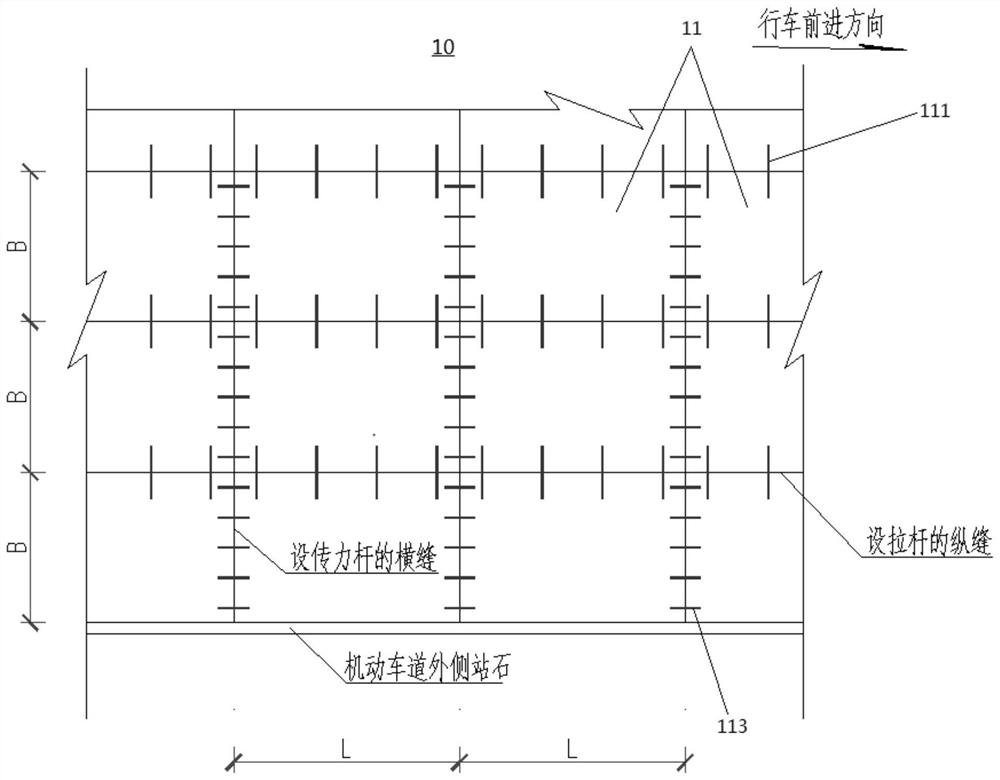

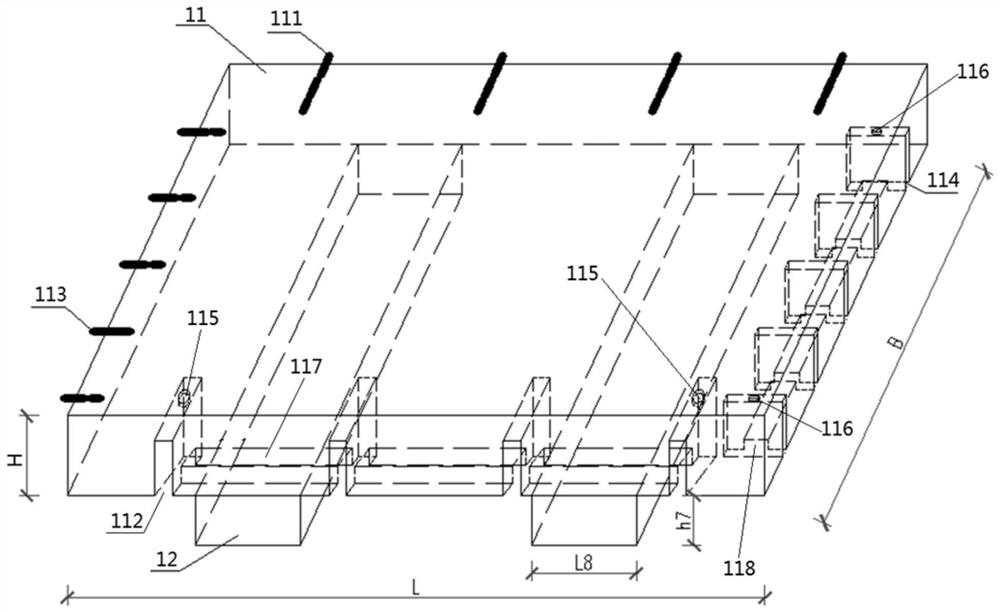

[0042] like Figure 1-7 As shown, a prefabricated concrete pavement with convex falcons includes a bottom-up pavement structure base and a concrete layer.

[0043] see figure 1 , the concrete layer is assembled by a number of prefabricated concrete slabs, the long side of the precast concrete slab is used as the longitudinal side, parallel to the road centerline, and the short side is used as the transverse side, perpendicular to the road centerline. In this embodiment, the prefabricated concrete slab is a prefabricated ordinary cement concrete slab. In this embodiment, a 2m×3m×22cm slab is taken as an example, and other dimensions can be referred to for implementation.

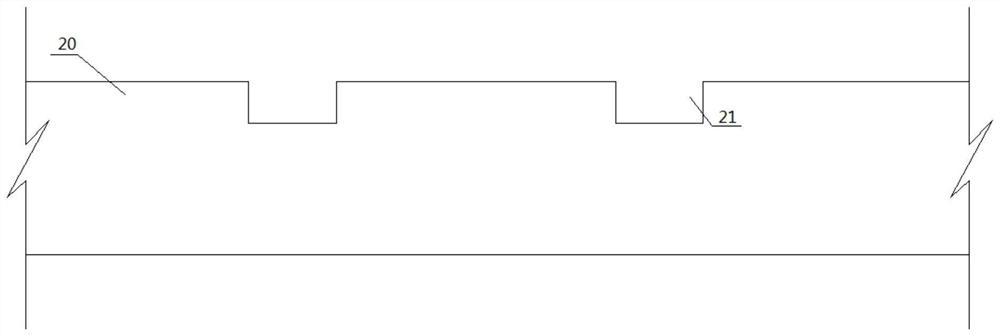

[0044] see figure 2 , the long side of one side of the precast concrete slab is provided with a tie rod, and the other long side is provided with a first groove adapted to the tie rod; one short side of the precast concrete slab is provided with a dowel bar, and the other short side is provided with a dowe...

no. 2 example

[0056] The difference between the prefabricated concrete pavement with convex falcons proposed in this embodiment and the first embodiment is that the prefabricated concrete slab is a prefabricated reinforced concrete slab, and the tie rods set on the long side of the reinforced concrete slab use horizontal steel bars extending L 9 =40cm instead, see Figure 8 . The distance between the transverse reinforcement and the bottom of the reinforced concrete slab is H / 3=7.33cm, 7cm is taken, and the diameter of the transverse reinforcement is 18mm. The first groove fitted with the tie rod is opened from the bottom of the reinforced concrete slab, with a width of 4cm and a length of L 10 Not less than the extension length L of the transverse reinforcement 9 ,high Take 8.5cm, and the position corresponds to the outstretched transverse steel bar, and set a first opening with a diameter of 3cm above the two first grooves on the edge of the concrete slab, as a grouting hole and an ai...

no. 3 example

[0062] A prefabricated concrete pavement with convex falcons proposed in this embodiment, on the basis of the first embodiment or the second embodiment, also includes anti-cracking stickers or polyester fiberglass cloth, adhesive layer oil and laying on the concrete layer asphalt pavement, forming a composite pavement, see Figure 9 . The assembled concrete layer in this embodiment can be a prefabricated ordinary cement concrete slab or a prefabricated reinforced concrete slab, which can be selected according to the actual requirements of the project. The prefabricated ordinary cement concrete slab is consistent with the relevant requirements in the first embodiment, and the prefabricated reinforced concrete slab is consistent with the relevant requirements in the second embodiment.

[0063] The asphalt surface layer can be selected according to the actual requirements of the project. In this embodiment, 4cm AC-13 fine-grained asphalt concrete + 6cm AC16 medium-grained asphal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Board width | aaaaa | aaaaa |

| Board length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com