Reinforced wind-clamping-resistant system of metal roof board

A metal roof and panel technology, which is applied in the direction of roof, roof covering, roof using flat/curved panels, etc., can solve the problem of low wind load bearing capacity of connection nodes, weak wind resistance performance, and resistance to wind pressure of connection nodes. Weak wind resistance and other problems, to reduce the possibility of local wind wind damage, improve the wind load bearing capacity, and enhance the wind resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

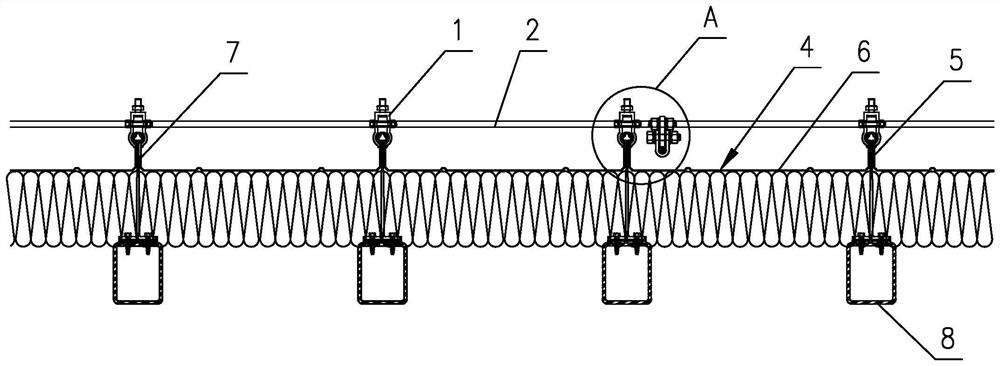

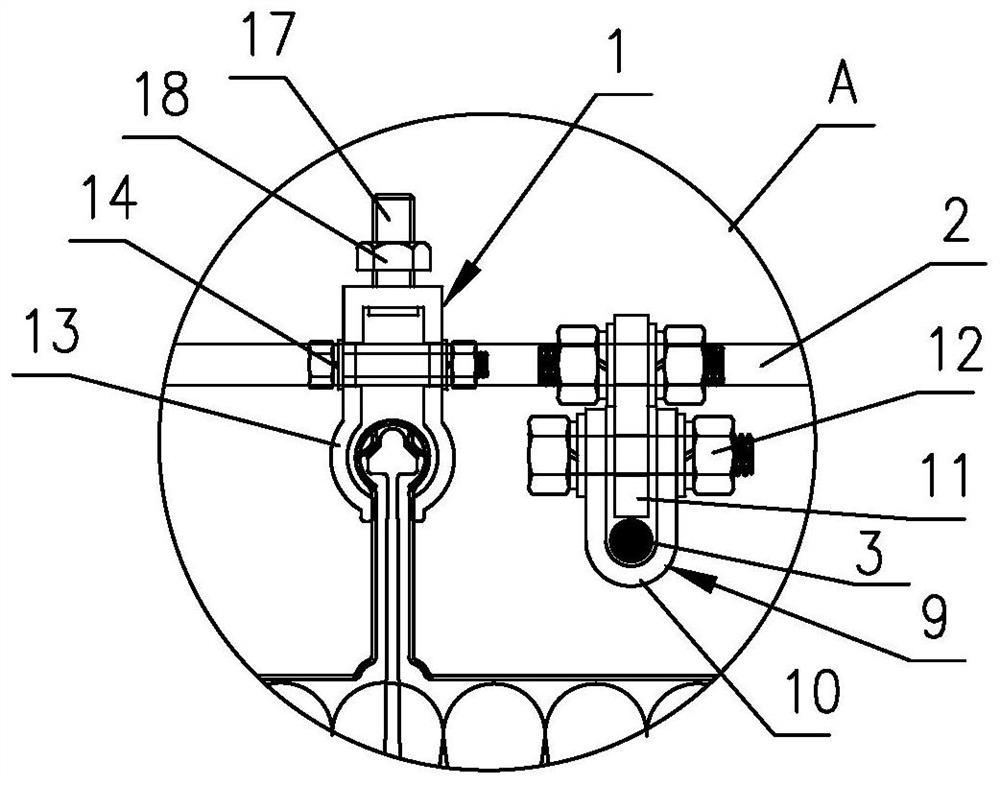

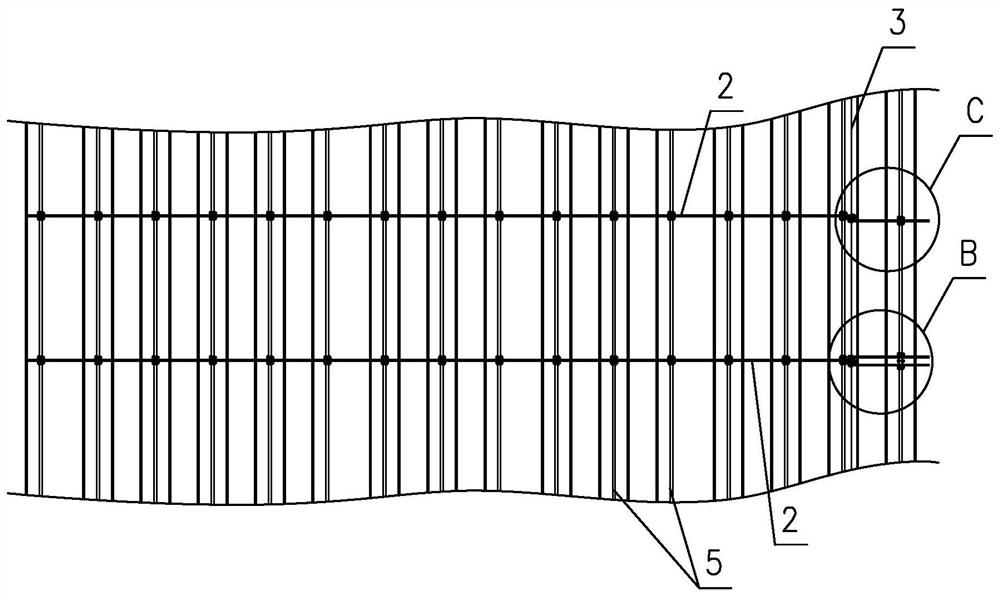

[0029] Such as Figure 1~5 As shown, it is a metal roof panel reinforced wind-resistant clip system of the present invention, which includes connecting units. In this embodiment, each group of connecting units includes several groups of wind-resistant clips 1 and connecting rods 2, and several groups of connecting units A wind-resistant clamp 1 is sequentially clamped on each plate rib 5 of the metal roof panel 4, and the plate rib 5 is the ear of the adjacent U-shaped roof panel 6, which is mechanically snapped on the plum blossom head at the upper end of the T-shaped support 7. formed. The connecting rod 2 is a stainless steel rod, which spans the metal roof panel 4 and passes through each wind-resistant clip 1 . A number of prestressed cables 3 are provided along the longitudinal extension of the metal roof panel 4, each prestressed cable 3 is connected to the connecting rod 2, and the prestressed cables 3 are parallel to the plate ribs 5, and the prestressed cables 3 Bot...

Embodiment 2

[0036] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that a keel 15 and a decorative plate 16 laid on the keel 15 are arranged above the metal roof panel 4, and the decorative plate 16 is fixed on the keel 15 by angle steel and bolts , the anti-wind clip 1 is connected with the keel 15. Specifically, a connecting structure for connecting the keel 15 is provided at the upper end of the wind-resistant clamp 1, see figure 2 , the connection structure is a hole, which is used to cooperate with the fastener 17 and the nut 18 to be fixed on the fixed plate 19 connecting the keel 15, the upper part of the fixed plate 19 is fixed on the keel 15 by bolts, and its lower end has a horizontal flange, fastening Part 17 passes through the folded edge and is then fixed by nuts to connect the wind-resistant clip with the keel. Layer decorative panels can improve the aesthetics of building roofs.

[0037] In other embodiments, each group of connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com