Cemented filling method using barren rock machine-made sand as aggregate

A technology of cemented filling and machine-made sand, which is applied in the direction of filling, earth drilling, safety devices, etc., which can solve the problems of increasing the risk of secondary geological disasters, costing a lot of manpower, material resources, and large land resources, so as to reduce environmental restoration The effect of reducing treatment costs, reducing mine production costs, and alleviating environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] A cemented filling method using waste rock machine-made sand as aggregate, comprising the following steps:

[0028] Step a: remove impurities, remove impurities in waste rocks; remove waste steel bars, nonel residues and other impurities in waste rocks;

[0029] Step b: crushing, the waste rock is subjected to coarse crushing, medium crushing and fine crushing in sequence; coarse crushing, medium crushing and fine crushing are carried out by using a jaw crusher;

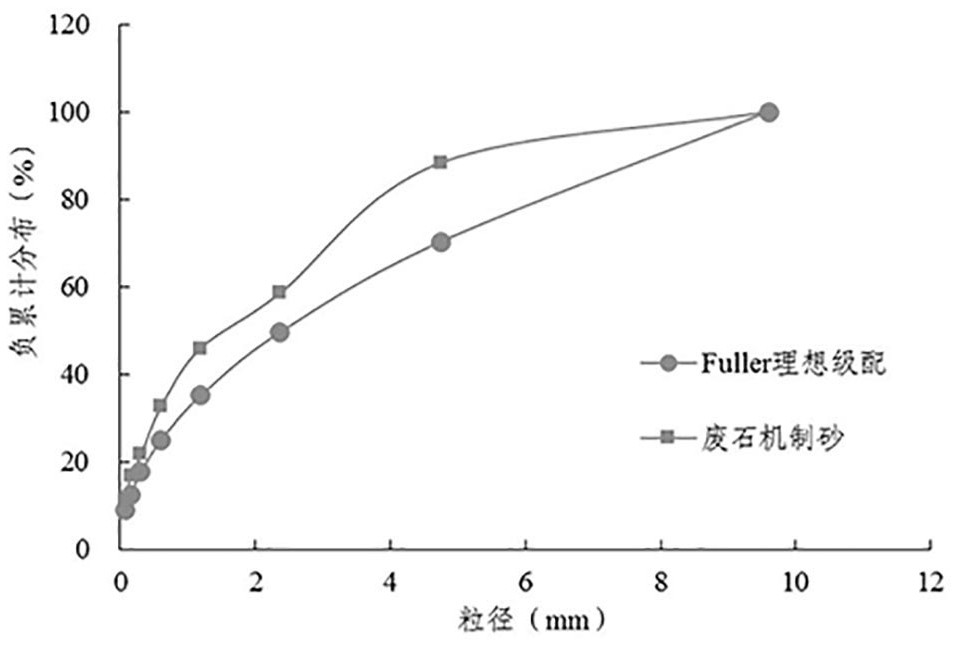

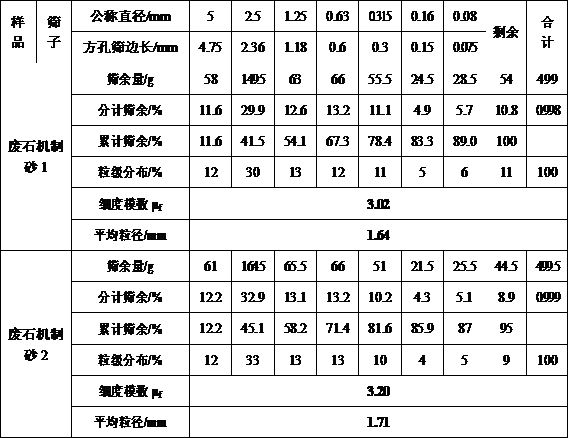

[0030] Step c: sieving, sieving the finely crushed waste rock, producing machine-made sand through sieving, and performing sieving operation through a vibrating sieve;

[0031] Step d: Screening experiment, carry out screening experiment on the machine-made sand, and carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com