Slag inhibitor adding nozzle for boiler

A technology of anti-slag agent and nozzle, which is applied in the field of pulverized coal boiler combustion, can solve the problems of high cost of anti-slag agent, inability to operate continuously and reliably, and low utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

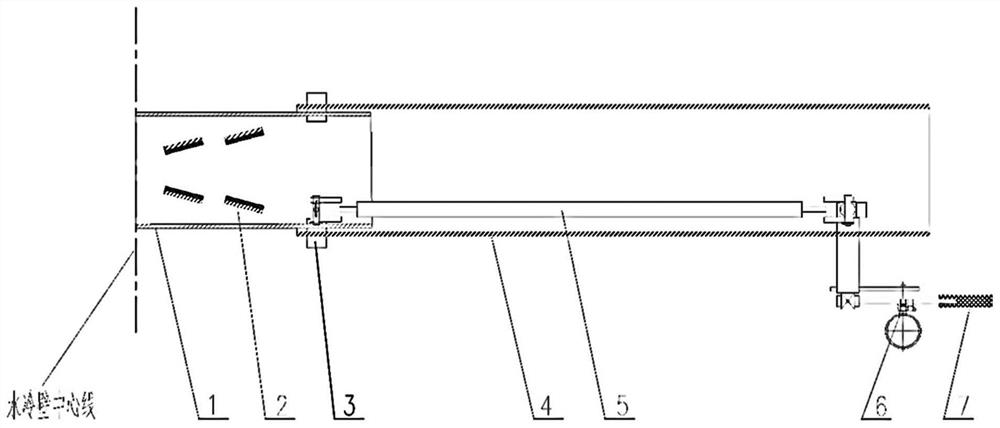

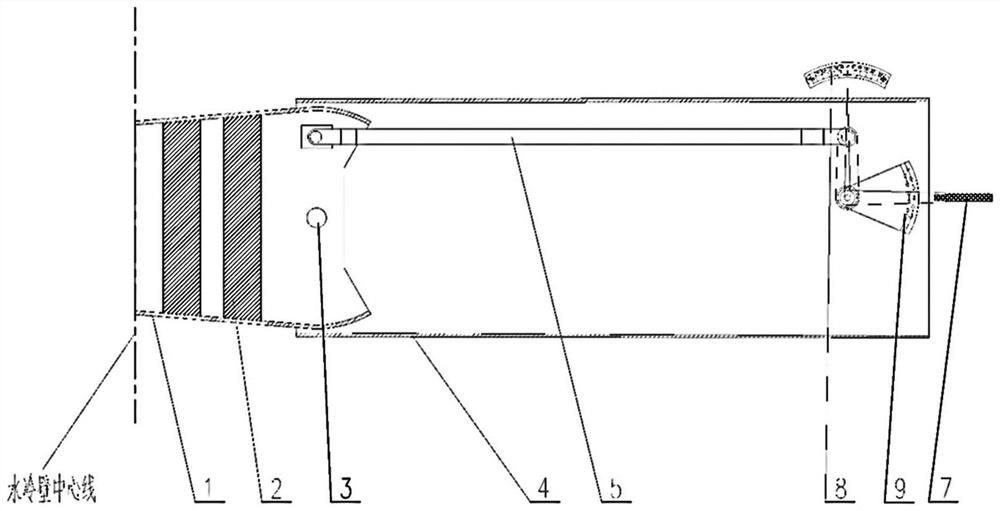

[0025] Such as figure 1 , 2 As shown, a kind of boiler antislagging agent provided by the invention adds spout, specifically as follows:

[0026] (1) A nozzle for adding anti-slag agent to a boiler, including a swingable anti-slag agent nozzle 1 and an air channel 4 for the anti-slag agent nozzle. Connected with each other, the front end of the swingable anti-slag agent nozzle 1 is provided with a two-stage anti-slag agent concentration deflector 2, one end of the nozzle swing linkage mechanism 5 is connected to the swingable anti-slag agent nozzle 1, and the other end is controlled by the anti-slag agent nozzle. 4. After passing through the inside, it is connected to the spout swing angle adjustment handle 7. The spout swing angle adjustment handle 7 is provided with a spout swing angle indicator 8 and a pin shaft fixing plate 9. The vertical swing angle o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com