Limited angle torque motor mechanical zero position marking method

A torque motor, limited rotation angle technology, applied in the field of machining, can solve the problems of low efficiency, cumbersome, long marking time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

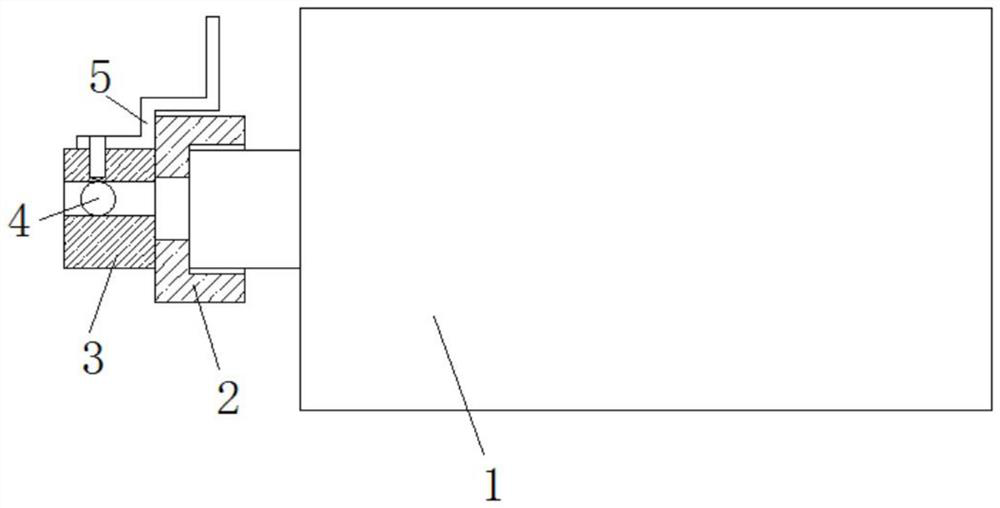

[0025] see Figure 1-2 : A method for marking the mechanical zero position of a limited-angle torque motor, comprising the following steps:

[0026] S1. Install the first shaft sleeve 2, the second shaft sleeve 3 and the pointer 5 on the output shaft end of the limited rotation angle torque motor 1 according to the use requirements. The end of the output shaft of the limited rotation angle torque motor 1 is equipped with an eccentric small ball 4 with small eccentricity. The ball 4 is integrated with the output shaft of the limited-angle torque motor 1, and then calibrated;

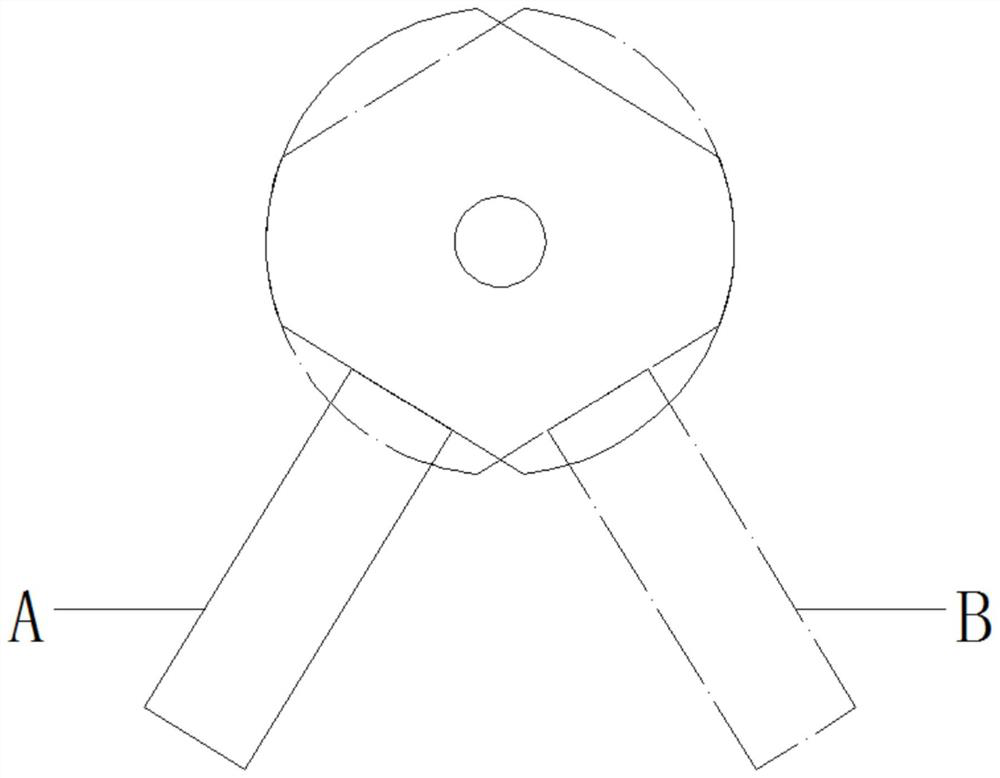

[0027] S2. Start the limited-angle torque motor 1, and first control the limited-angle torque motor 1 to rotate forward. At this time, the limited-angle torque motor 1 will drive the pointer 5 to rotate to the limit angle position at one end, mark A along one side with a marker, and then Then control the limited rotation angle torque motor 1 to reverse, at this time, the limited rotation angle torque mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com