Workshop equipment energy online monitoring and control system

A technology for workshop equipment and control systems, which is applied in general control systems, control/regulation systems, program control, etc., and can solve problems such as abnormal signals and no control measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

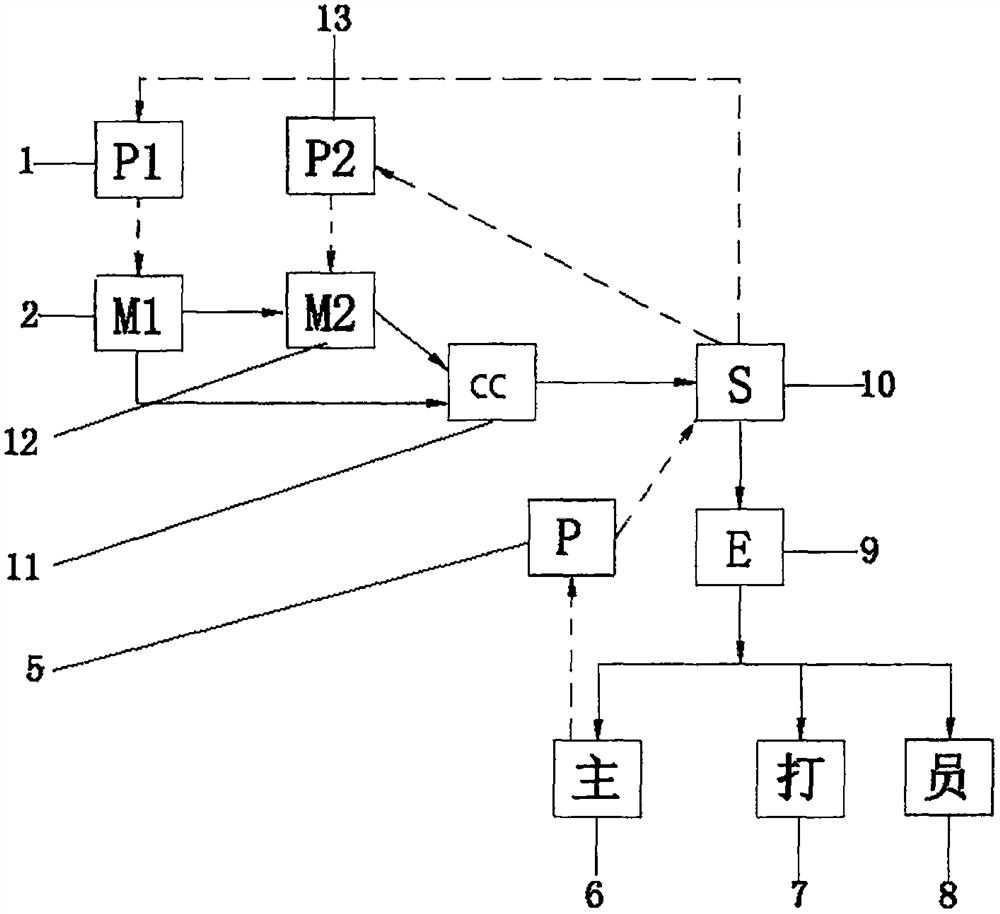

[0050] Such as figure 1 The workshop equipment energy online monitoring and control system, machine 1 and machine 2 are connected in series.

[0051] The hardware architecture adopted includes: each machine to be monitored in the workshop is equipped with its own PLC controller to collect the start-up signal of the device, equipped with an EMU4-HD power module to collect the real-time power data of the machine; or equipped with a pulse module A to collect the cooling water consumption of the machine Data, or equipped with pulse module B to collect the data of natural gas consumption of the machine; then use the CC-Link communication module to connect each machine separately, as the communication slave station for the above-mentioned one, two, three, or four kinds of data of each machine; Then connect the CC-Link communication module to the server as the communication master station; the built-in control software in the server can input and set the standard data parameters of e...

Embodiment 2

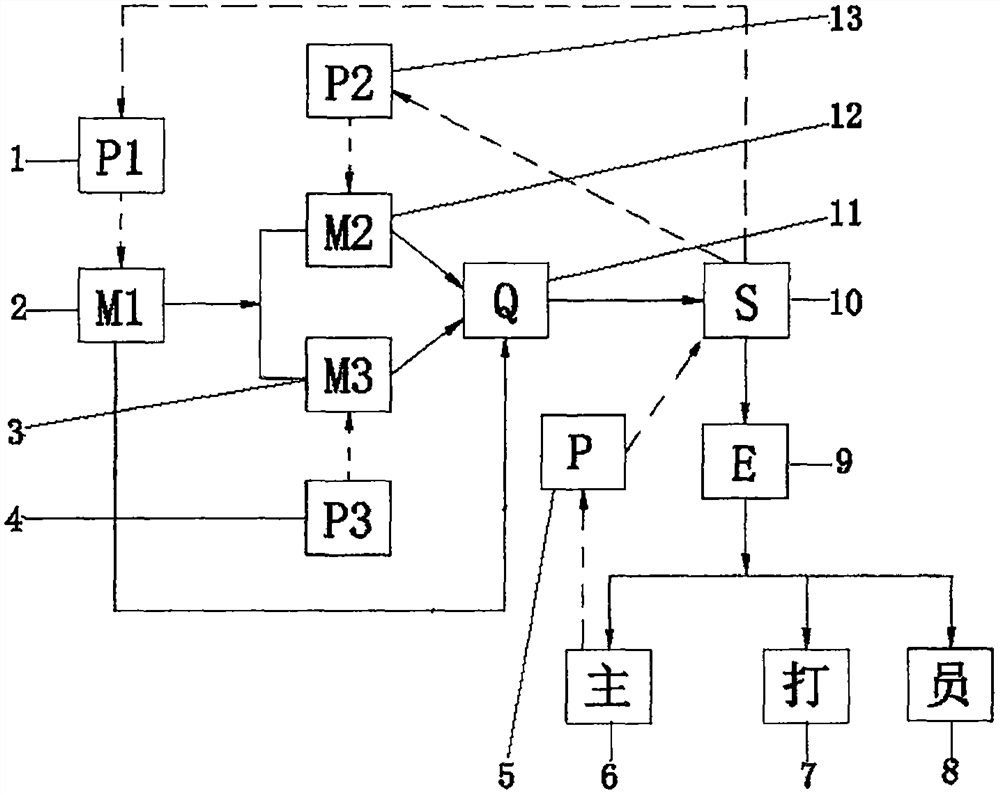

[0055] As shown in the online monitoring and control system of equipment energy in workshop 2, machine 2 and machine 3 are connected in parallel.

[0056] The hardware architecture adopted includes: each machine to be monitored in the workshop is equipped with its own PLC controller to collect the start-up signal of the device, equipped with an EMU4-HD power module to collect the real-time power data of the machine; or equipped with a pulse module A to collect the cooling water consumption of the machine Data, or equipped with pulse module B to collect the data of natural gas consumption of the machine; then use the QJ61BT11N module to connect each machine separately, as the communication slave station for the above-mentioned one, two, three, or four kinds of data of each machine; then QJ61BT11N The module is connected to the server as the communication master station; the built-in control software in the server can input and set the standard data parameters of each machine, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com