Magnetic torquer for microsatellite and assembly method thereof

A technology of magnetic torquer and micro-satellite, which is applied in transformer/inductor magnetic core, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc. It can solve the problems of weak protection ability, poor practicability, high weight of magnetic torquer, etc. Problems, to achieve the effect of high protection, improved protection, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

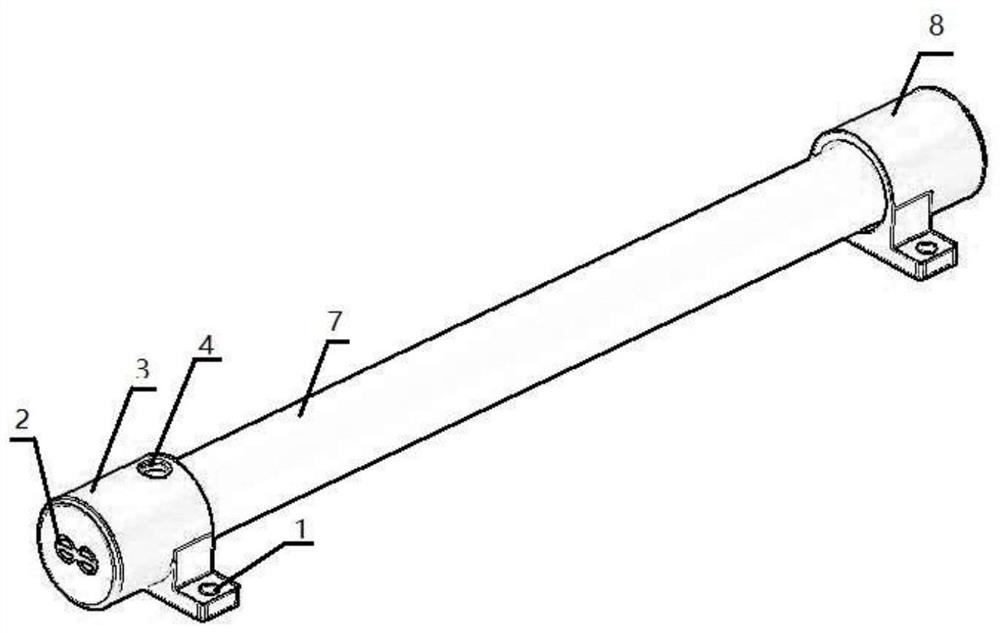

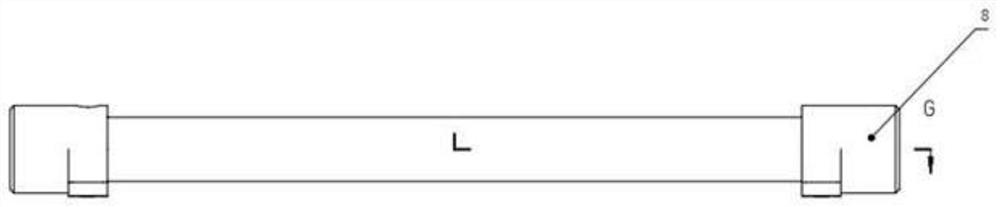

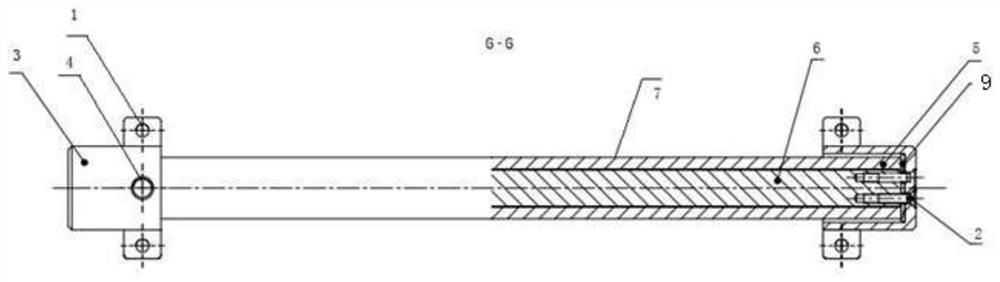

[0030] A magnetic torque device for micro-satellites, such as Figure 1-3 As shown, it includes a left mounting frame 3, a coil 5, a magnetic core 6, a right mounting frame 8, a left insulating barrier (not marked in the figure) and a right insulating barrier 9. This magnetic torquer can be directly applied to a 50Kg class microsatellite , the magnetic core 6 is respectively threaded with the left mounting frame 3 and the right mounting frame 8 using titanium nails 2, and the assembly is sealed with D04 glue. The magnetic core 6 adopts permalloy national standard 1J85, and its diameter is The length is 220mm. This material has outstanding advantages such as small size, light weight, fast response, high magnetic moment output accuracy, and high reliability. It meets the lightweight design, reduces the residual magnetism to an extremely small range, and has high output accuracy. Coil 5 adopts a single-layer polyimide enameled wire to be wound on the surface of the magnetic cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com