Method for repairing circuit of electronic display screen by using ITO (Indium Tin Oxide) electrode

A display screen and circuit technology, applied in printed circuit, printed circuit manufacturing, circuit substrate materials, etc., can solve problems such as unusable, environmental pollution, and no way of mechanical repair, etc., and achieve the effect of rapid and complete repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

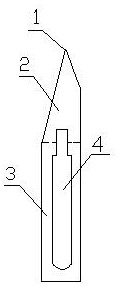

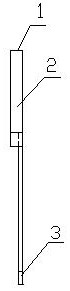

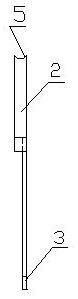

[0013] A kind of method of repairing electronic display screen circuit with ITO indium tin oxide electrode described in the present invention, first use No. 11 blades to cut off the protective layer and isolation layer on the display screen, expose the damaged display screen circuit, and stick the After the residue attached to the glass is polished and cleaned, place the IT0 wire on the scraped place, use the scraper to form a groove on the display screen according to the circuit repair trend, and use a scraper (pointed-shaped Such as figure 1 As shown) stick it on the IT0 indium tin oxide wire and rub it back and forth to make the nano-indium tin oxide wire rub against and generate heat, and use the friction heat to turn the IT0 wire into a molten IT0 indium tin oxide film, and at the same time use a scraper to oxidize the molten IT0 The indium tin film is filled in the groove to form a continuous IT0 indium tin oxide electrode to repair the electronic display circuit. Finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com