Lifting and hoisting integrated culture machine for ocean engineering equipment

An ocean engineering and integrated technology, which is applied in the field of aquaculture machines based on lifting and hoisting integrated marine engineering equipment, can solve problems such as excessive resource cost consumption and efficiency problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

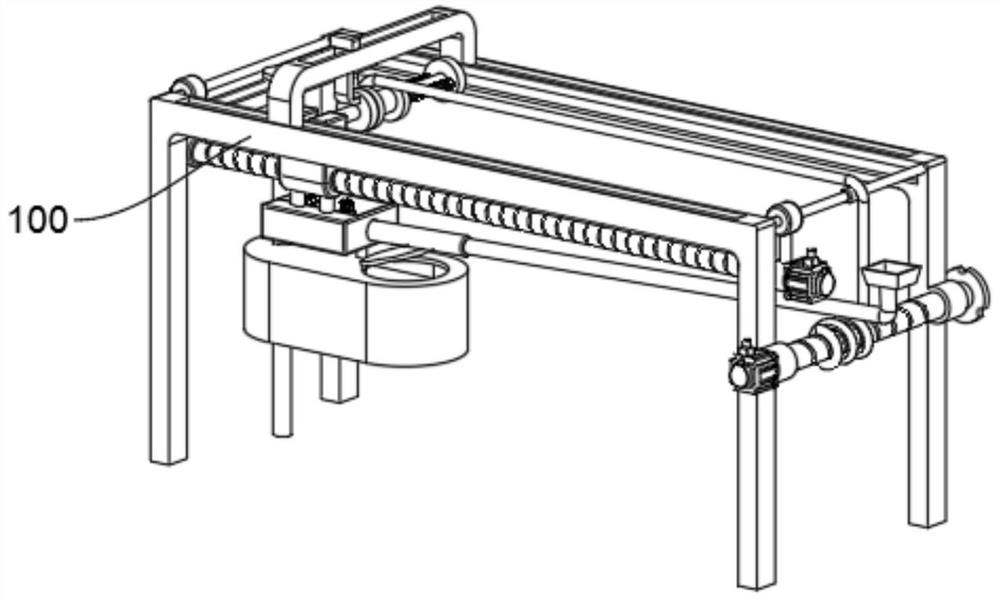

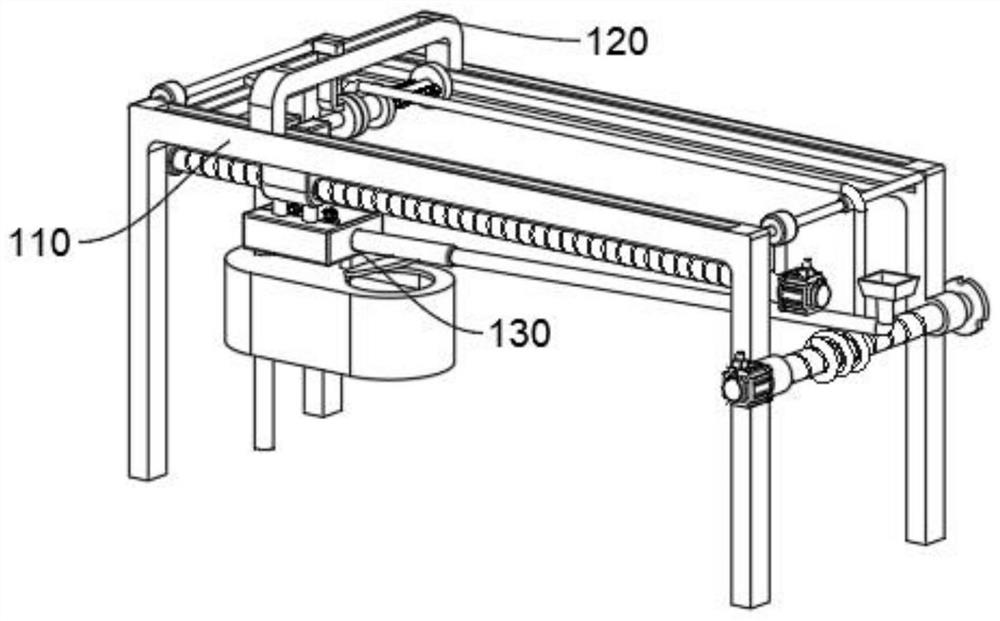

[0043] see Figure 1-Figure 8 As shown, the purpose of this embodiment is to provide a cultivating machine based on lifting and hoisting integrated marine engineering equipment, including a culturing device 100, and the culturing device 100 at least includes:

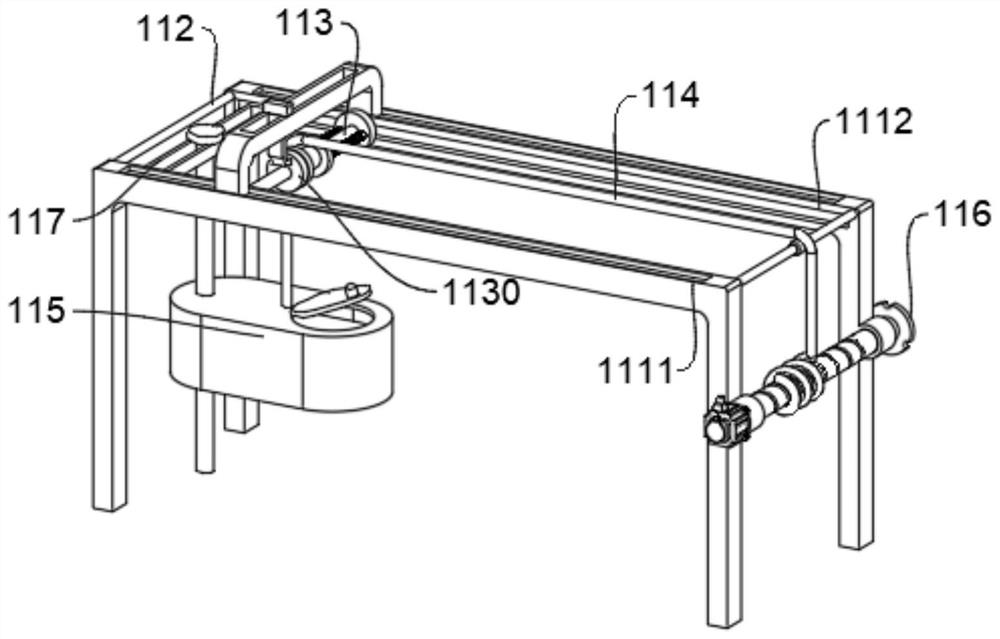

[0044] The culture body 110, the culture body 110 includes a symmetrically arranged fixing frame 111, the surface of the fixing frame 111 is provided with an upper cavity 1111, the fixing frames 111 are fixedly installed by connecting rods 112, and the fixing frames 111 are connected by rotation through fixing rods 113. There is a pulley 1130, the surface of the pulley 1130 is provided with a pulling rope 114, and one end of the pulling rope 114 is provided with a breeding room 115;

[0045] During the specific use of the culture body 110 of the present invention, the fishes are placed inside the culture chamber 115, and are released and extended to one end through the pull rope 114, so that the culture chamber 115 is dow...

Embodiment 2

[0054] In order to solve the problem that the whole device is not convenient enough for feeding the breeding room 115, the following improvements are made on the basis of Example 1:

[0055] see Figures 9-10 As shown, a guide discharge assembly 130 is arranged inside the culture body 110, and the guide discharge assembly 130 includes a fixed ring 131 installed on the surface of the connecting rod 112. An offset block 134 is screwed on the surface, the top of the offset block 134 is clamped with the fixing rod 113, and the bottom of the offset block 134 is connected with a feeding bin 135 through the rod body, and a screw rod is rotatably connected to one end of the screw rod 132 Motor 133, so that the screw motor 133 is connected to the power supply, so that the screw 132 rotates, and the offset block 134 performs a synchronous lateral offset to the position of the fixed rod 113, which saves manpower when adjusting the position of the fixed rod 113, and at the same time when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com