Device for purifying trimethylsilyl trifluoromethanesulfonate

A technology of trimethylsilyl trifluoromethanesulfonate and mounting blocks, which is applied in the direction of silicon organic compounds, compounds of Group 4/14 elements of the periodic table, distillation and separation, etc., and can solve the problem of easy hydrolysis to form trifluoromethanesulfonic acid and trimethylsilanol, increased impurity content, and easily corroded equipment to achieve the effect of promoting rapid heating and gasification, increasing the efficiency of purification, and increasing the amount of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

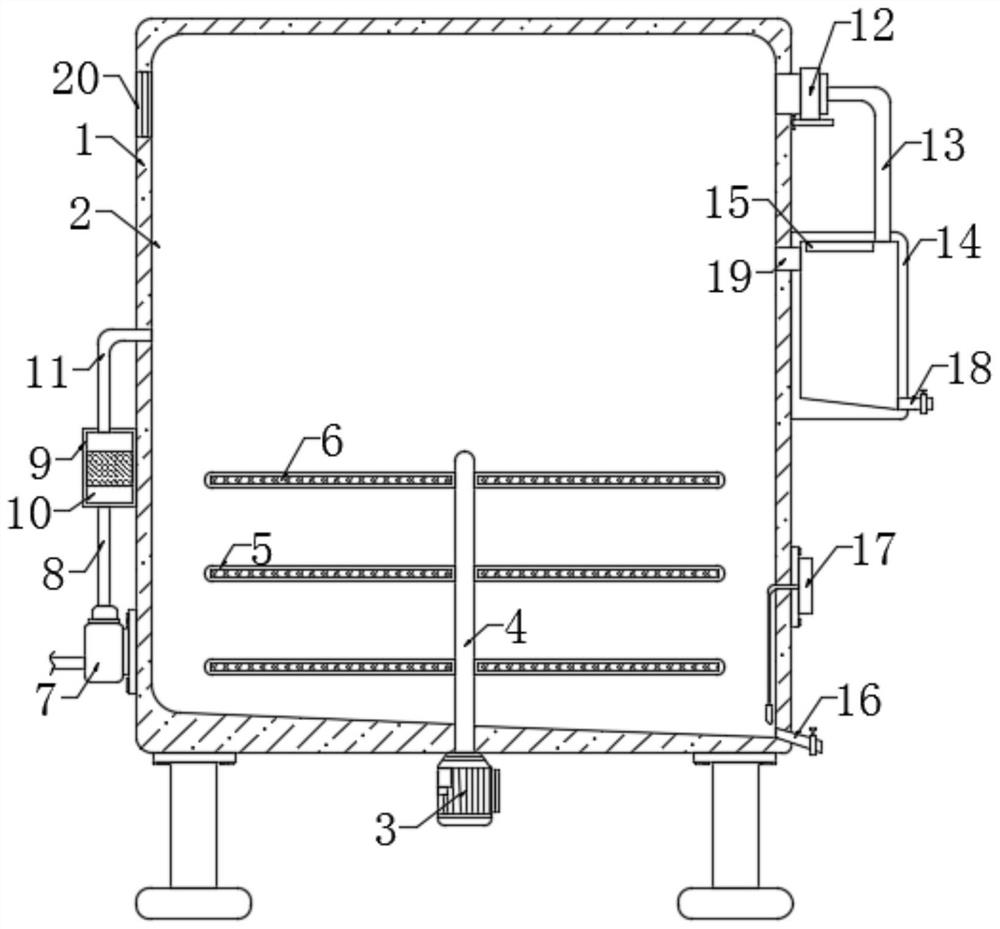

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

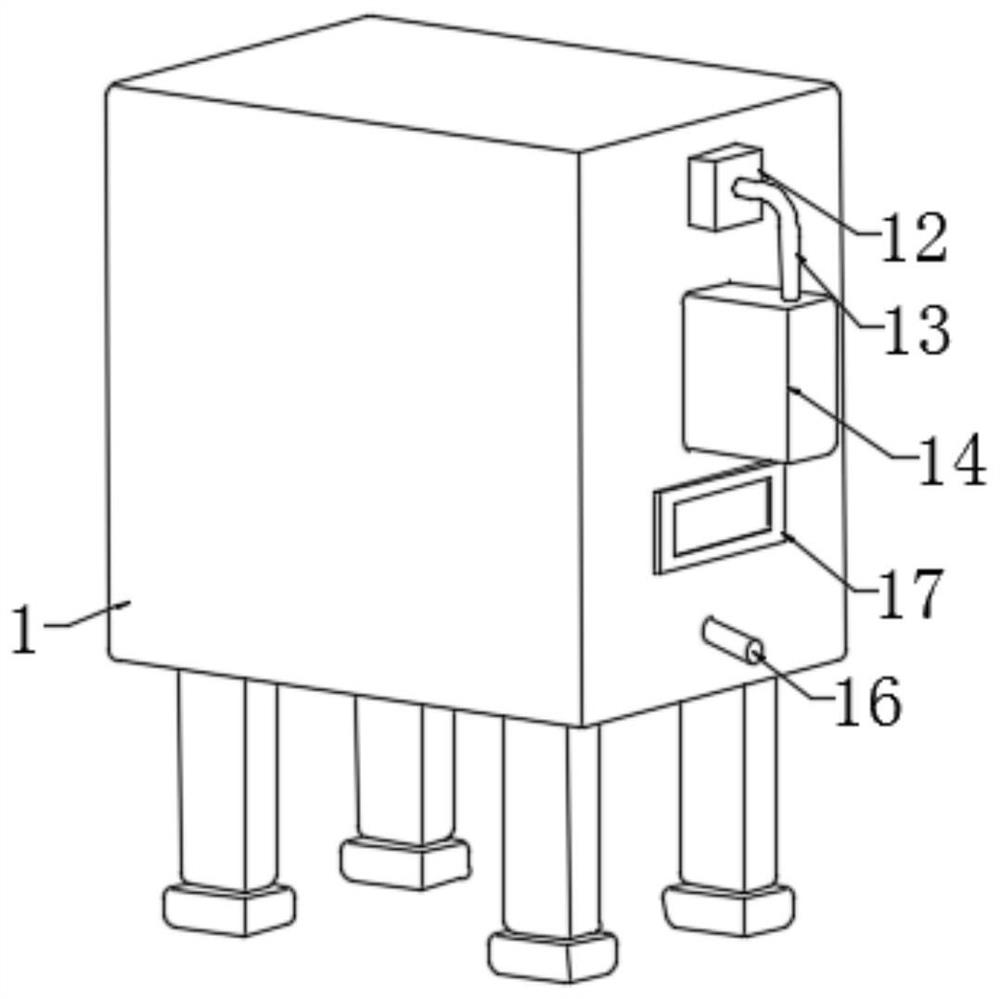

[0020] refer to Figure 1-2 , a device for purifying trimethylsilyl trifluoromethanesulfonate, comprising a box body 1, a distillation chamber 2 is arranged in the box body 1, an installation block 9 is installed on the left side of the box body 1, and an installation block 9 is provided with Drying chamber 10, the right end of box body 1 is provided with collection box 14, and collection box 14 is provided with collection chamber, and the left space of collection chamber communicates with the right side space of distillation chamber 2 through short pipe 19, and the right side of box body 1 A fan 12 and a temperature display 17 are installed, and the temperature display 17 is used to better grasp the temperature in the distillation chamber 2. The temperature display 17 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com