Production device for PVC (polyvinyl chloride) plastic film recycling

A production device and plastic film technology, which is applied in the field of plastic film production, can solve the problems of waste of resources and waste of plastic film scraps, and achieve the effects of saving resources, realizing recycling, and improving cutting efficiency and crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

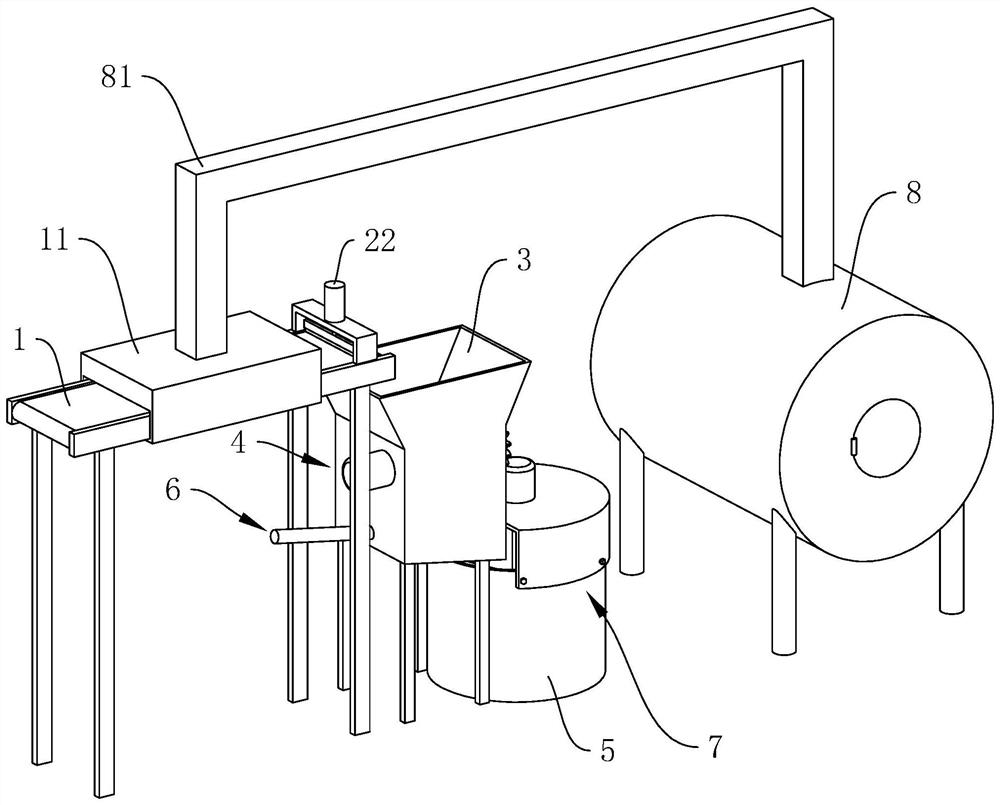

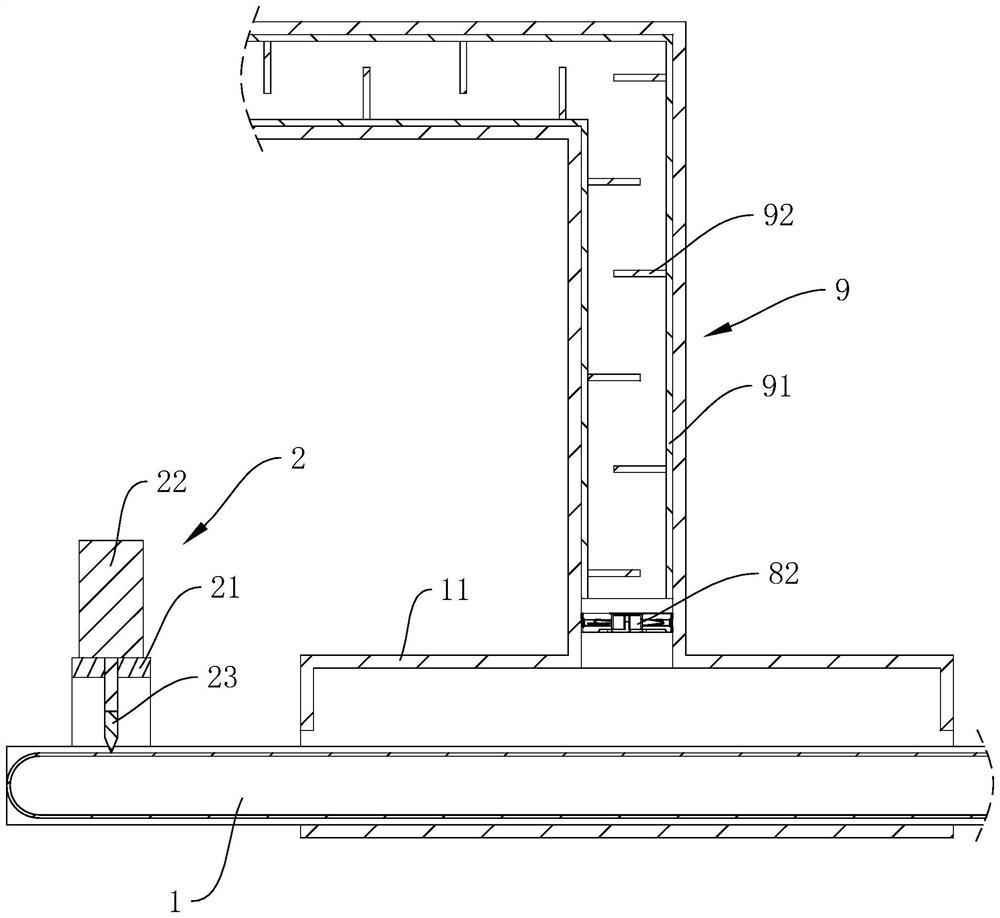

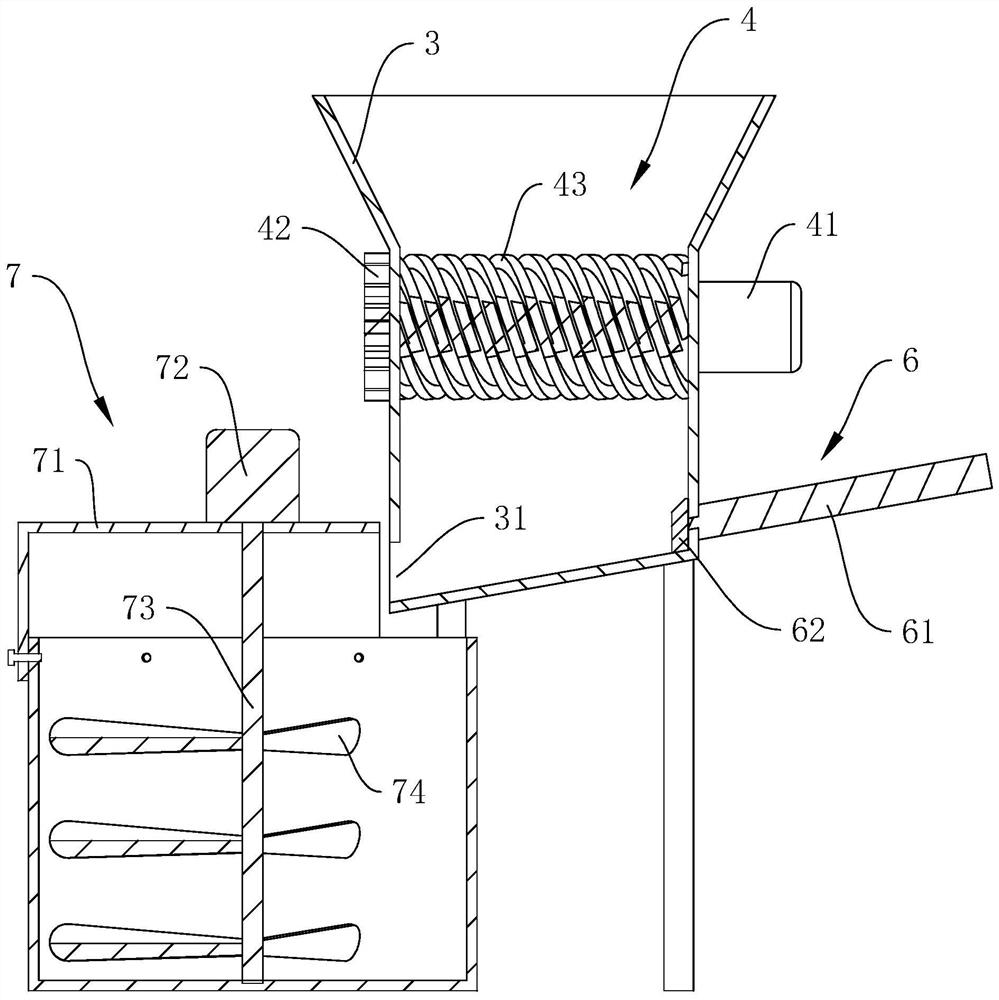

[0039] refer to figure 1 with figure 2 , a production device for recycling PVC plastic film includes a conveyor belt 1 for transporting trimmings, the conveyor belt 1 is provided with a cutting mechanism 2 for cutting trimmings; one side of the conveyor belt 1 is provided with a crushing box 3 that is provided with an upper flare, The upper opening of the crushing box 3 is located directly below the end of the conveyor belt 1, and the crushing box 3 is provided with a crushing mechanism 4 for crushing the cut side material. The bottom of the crushing box 3 side walls is provided with a discharge port 31. 3 The bottom is provided with a feeding mechanism 6 for pushing the pulverized powder out of the outlet 31; one side of the crushing box 3 is provided with a mixing drum 5 with an upper opening, and the upper opening of the mixing drum 5 is located directly below the outlet 31, The mixing drum 5 is provided with a stirring mechanism 7 for evenly stirring the collected powder...

Embodiment 2

[0048] refer to Figure 4 , the difference with Embodiment 1 is that the feeding mechanism 6 includes a vibrating plate 63, a vibrating motor 64 and some springs 65, there is a distance between the bottom of the discharge port 31 and the inner bottom wall of the pulverizing box 3, and the vibrating plate 63 is inclined Set in the crushing box 3, the bottom of the vibrating plate 63 extends out of the discharge port 31, the spring 65 is fixed between the lower surface of the vibrating plate 63 and the inner bottom wall of the crushing box 3, and the vibrating motor 64 is fixed on the lower surface of the vibrating plate 63 Each side wall of the vibrating plate 63 facing the crushing box 3 is fixed with an elastic plate 631 of rubber material, and the elastic plate 631 is pressed against the inner wall of the crushing box 3 . Start the vibrating motor 64 so that the vibrating plate 63 vibrates, the powder on the vibrating plate 63 is constantly vibrated out of the discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com