Tissue recovery system and tissue recovery method

A recycling system and paper towel technology, applied to paper, papermaking, cardboard items, etc., can solve the problems that it is inconvenient to improve the color consistency of recycled paper, and it is inconvenient to make long strips of waste paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

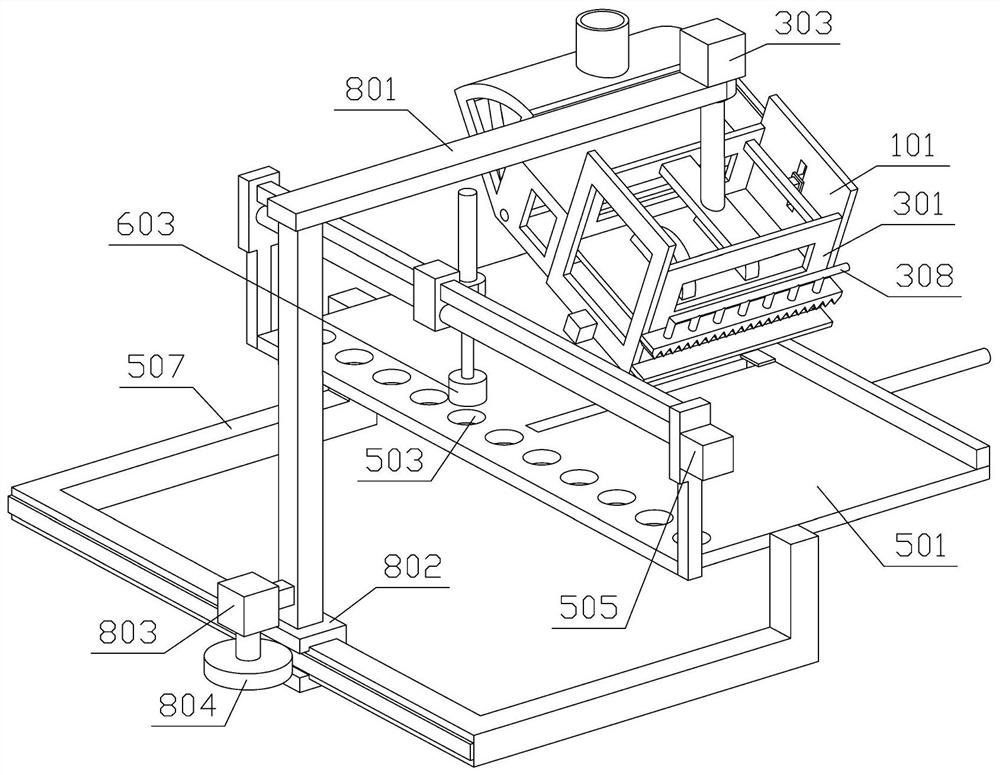

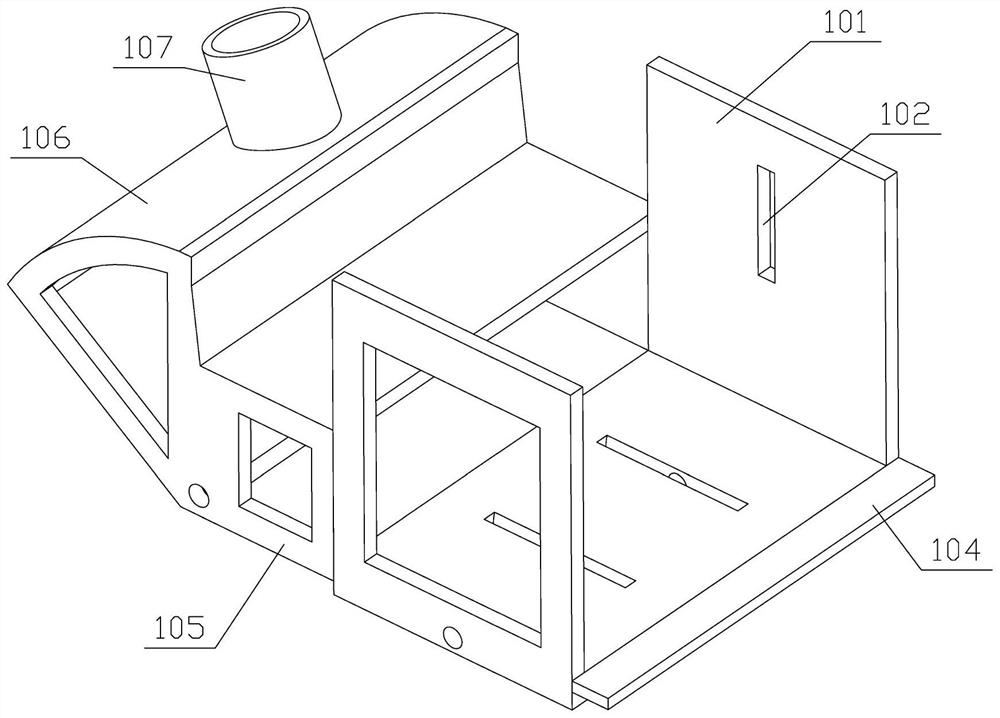

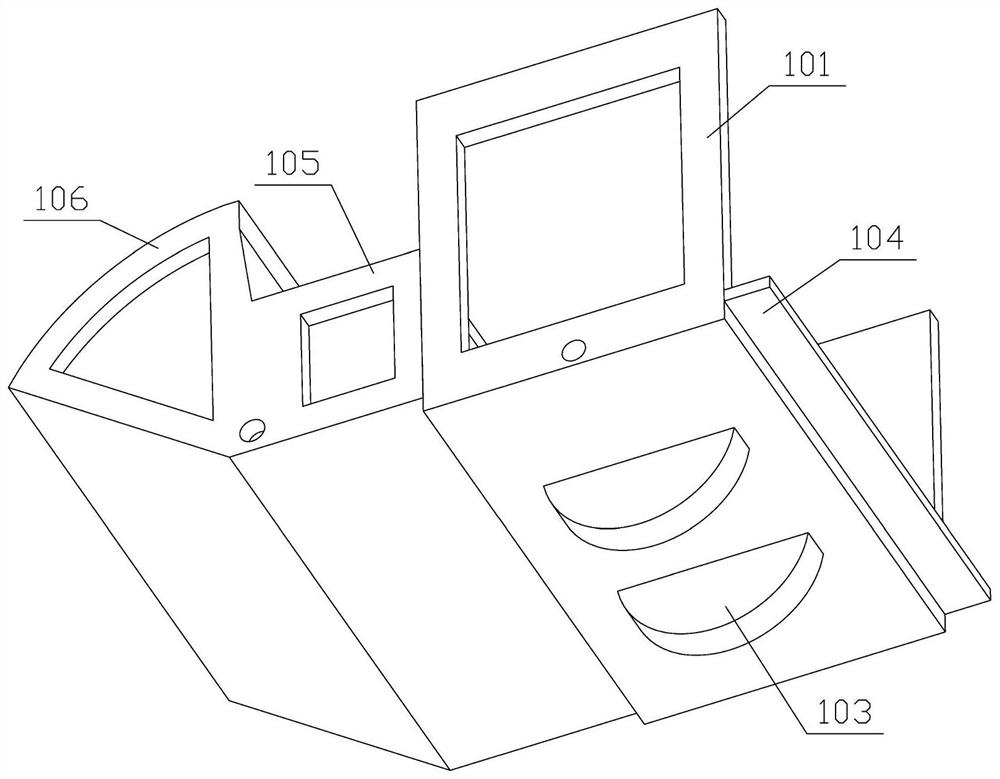

[0036] Combine below Figure 1-9 Describe this embodiment, the present invention relates to the technical field of paper towel recycling equipment, more specifically a paper towel recycling system, including a U-shaped plate 101, a lower transfer box 103, a cutting motor 201, a rotating shaft 202, a cutter 203, a pressing frame 301 and an upper Turning box 304, the present invention can make waste paper into long paper strips, and further, the present invention can improve the color consistency of recycled paper.

[0037]The bottom of the U-shaped plate 101 is fixedly connected and communicated with two lower transfer boxes 103, the output shaft of the cutting motor 201 is fixedly connected with a rotating shaft 202, and two cutting knives 203 are installed on the rotating shaft 202, the cutting motor 201 and the U-shaped The plate 101 is fixedly connected, the rotating shaft 202 is hingedly connected with the U-shaped plate 101, the upper part of the press frame 301 is fixedl...

specific Embodiment approach 2

[0039] Combine below Figure 1-9 To illustrate this embodiment, the paper towel recycling system also includes a chute I102, a carriage I401, an electric push rod I402 and a rack post 403, and the U-shaped plate 101 is provided with a chute I102, a carriage I401 and a pressing frame 301 Fixed connection, the sliding frame I401 is slidingly connected in the chute I102, the fixed end of the electric push rod I402 is fixedly connected with the U-shaped plate 101, the movable end of the electric push rod I402 is fixedly connected with the sliding frame I401, and the sliding frame I401 is fixedly connected with Rack column 403; start the electric push rod I402 to expand and contract, so that the U-shaped plate 101 can move towards the direction close to the pressing frame 301, so as to continuously compact the waste paper, and at this time, the sliding frame I401 slides in the chute I102 .

specific Embodiment approach 3

[0041] Combine below Figure 1-9 To illustrate this embodiment, the paper towel recycling system further includes a transition box 105, a press-in box 106, a feeding pipe 107, a gear I 404, a pressing plate 405, and an overflow tank 406. The transition box 105 is fixedly connected to the U-shaped plate 101, and the transition The box 105 is attached to the side of the press frame 301. The transition box 105 is fixedly connected and communicated with the press-in box 106. The press-in box 106 is fixedly connected and communicated with the feeding pipe 107. The gear I404 is installed on the pressure plate 405, and the gear I404 It is connected to the rack column 403 in transmission, and the pressing plate 405 is hingedly connected with the pressing box 106. Two overflow grooves 406 are arranged on the pressing plate 405; the waste paper is continuously injected into the pressing box 106 through the feeding pipe 107, and the electric push rod I402 is started to carry out Telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com