An automatic water circulation system for a thermal power plant

A technology of water cycle and thermal power plant, applied in the field of water cycle, can solve the problems of cumbersome treatment methods and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

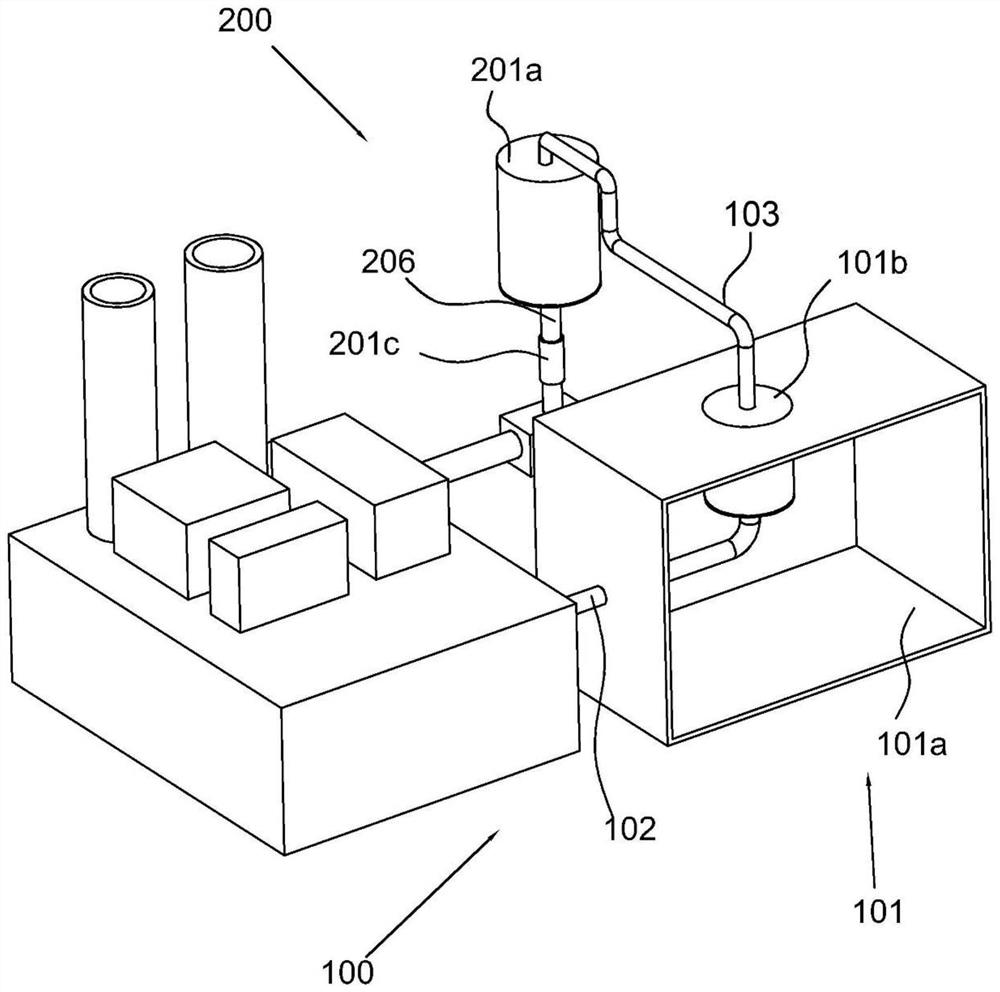

[0030] refer to Figure 1-5 , an automatic water circulation system for a thermal power plant, comprising, a circulation pipeline 100, including a distillation part 101, a water inlet pipe 102 directly connected to the distillation part 101, and a water outlet pipe 103 arranged at the other end of the distillation part 101, the water outlet pipe 103 and the water inlet pipe 102 There is a control valve on it; the condensation pipe 201b road 200 includes a condensation part 201 arranged at the end of the water outlet pipe 103 and a water circulation part arranged in the condensation part 201, and the other end of the water circulation part is provided with a water delivery part 202; and a cleaning assembly 400, The cleaning assembly 400 is connected to the water delivery unit 202 and the distillation unit 101 .

[0031] Specifically, the main structure of the present invention includes a circulation pipeline 100. In this embodiment, the circulation pipeline 100 includes a disti...

Embodiment 2

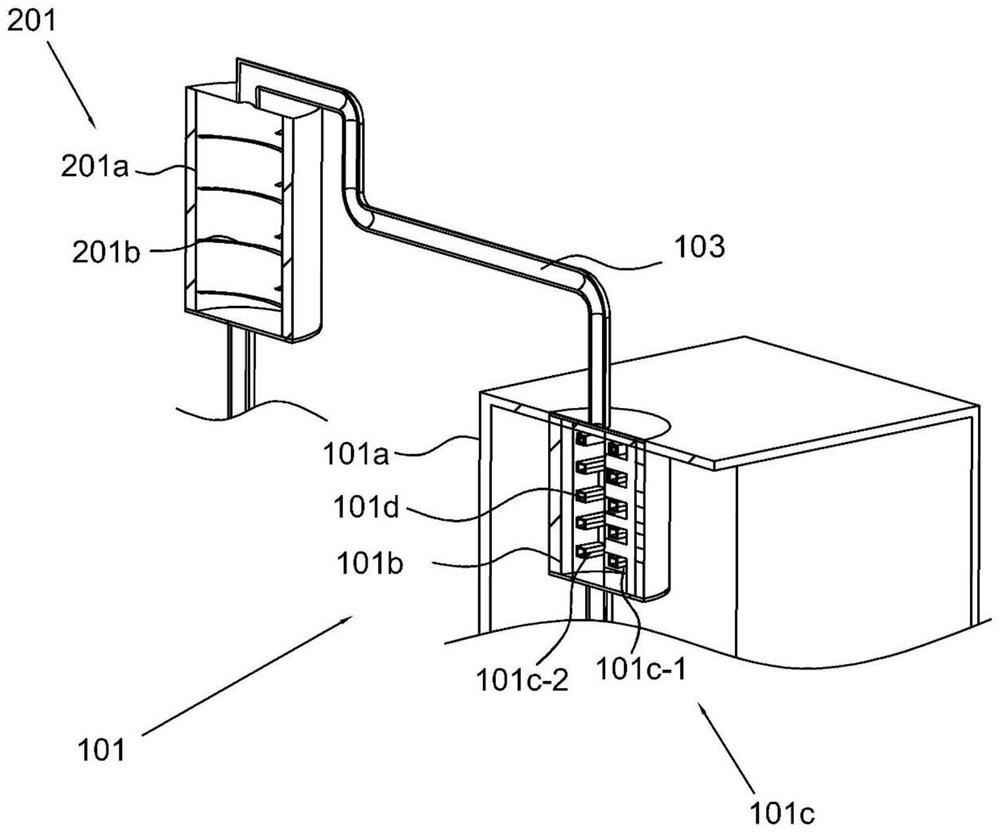

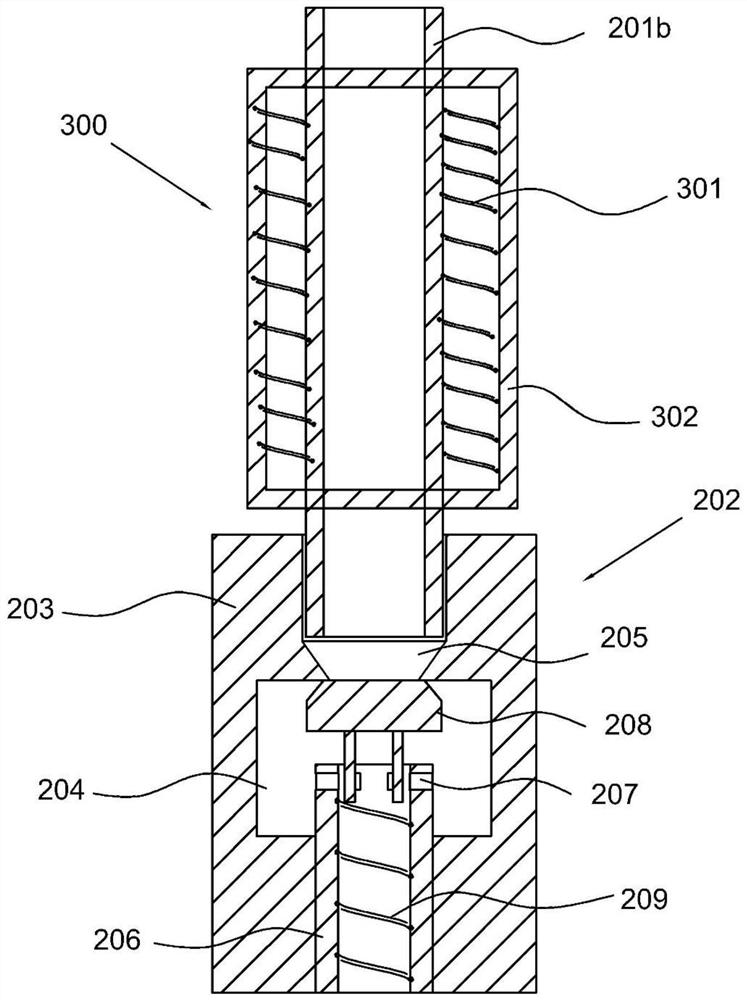

[0036] refer to Figure 1-5, this embodiment is different from the first embodiment in that the distillation part 101 includes a box body 101a, a distillation box arranged in the box body 101a and a heating element 101c arranged in the distillation box, and a heating tower 101b is arranged in the distillation box , the heating tower 101b is provided with a heating pipe 101d connected to the water inlet pipe 102, the heating pipe 101d is extended upward and is connected to the water outlet pipe 103, and the heating element 101c includes a heating hole 101c- 1. The heating wire 101c-2 arranged in the heating hole 101c-1 and the coating layer arranged outside the heating wire 101c-2, the coating layer is arranged in contact with the heating tube 101d, and the condensing element 201 includes a casing 101a provided The condensation chamber 201a at the upper position, the condensation pipe 201b spirally arranged in the condensation chamber 201a, and the outlet valve 201c arranged at...

Embodiment 3

[0045] refer to Figure 1-5 , this embodiment is different from the above embodiments in that the cleaning assembly 400 includes a water filter pipe 401 disposed at the end of the water pipe directly connected from the water delivery member 202, a filter screen 402 disposed in the water filter pipe 401, and a filter 402 that is rotatably connected to the The adsorption roller 403 at the rear end of the filter screen 402, wherein the adsorption roller 403 is provided with a clean water tank 404, and a switch plate 405 is rotatably connected to the notch of the clean water tank 404. The switch plate 405 is provided with a number of water filtering holes 405a. The inside of 405 is provided with a water filter bag 406, the water filter bag 406 is provided with volcanic stone debris, the upper end of the switch plate 405 is provided with a waste outlet 407, the water filter pipe 401 is rotatably connected with an opening plate 408, and the opening plate 408 and the water filter pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com