Multi-jet composite fluidized bed gasification device for coal and biomass

A fluidized bed gasification and biomass technology, which is applied in the direction of granular/powdered fuel gasification, can solve the problems of investment, operation and maintenance costs, etc., to improve fluidization performance, transfer and reaction enhancement, and guarantee The effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

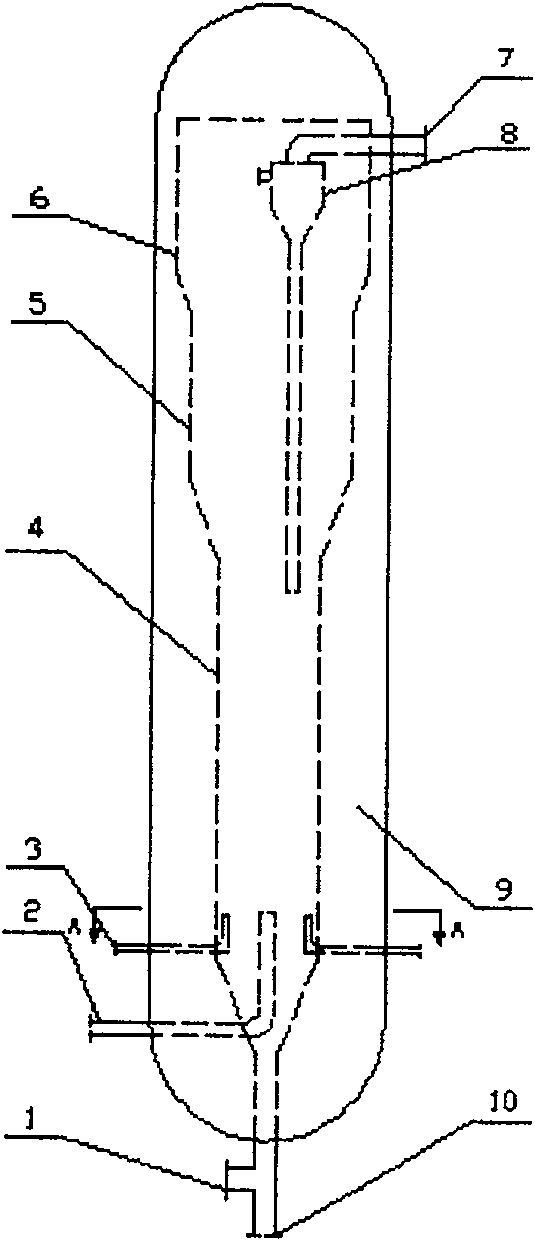

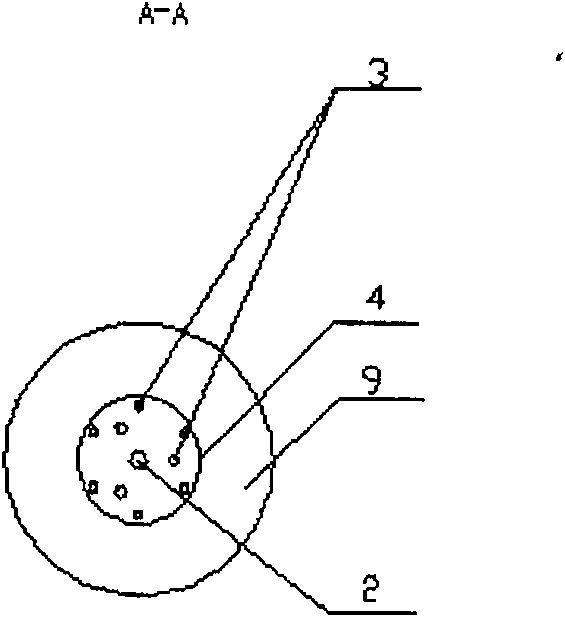

[0019] The fluidized bed consists of three parts: the lower bed body 4, the middle enlarged section 5 and the upper enlarged section 6. The diameter of the middle enlarged section 5 is larger than that of the lower bed body 4, the diameter of the upper enlarged section 6 is larger than that of the middle enlarged section 5, and the upper enlarged section There is a cyclone separator 8 in the section 6, the top of the cyclone separator 8 is the syngas outlet 7, the bottom of the lower bed body 4 has a conical structure, and the jet tube is divided into the main jet feed tube 2 and the auxiliary jet tube 3, and the bottom of the lower bed body 4 is in a conical structure. The tapered structure at the bottom of the body 4 is equipped with an auxiliary jet tube 3 in two layers along the radial direction, and a main jet feed tube 2 is installed at the center of the bottom of the lower bed body 4 and on the same level as the auxiliary jet tube 3, and the lower bed body 4. The bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com