Dielectric barrier temperature field furnace and its working method based on intermediate frequency heat concentration

A medium barrier and temperature field technology, applied in coking ovens, petroleum industry, biofuels, etc., can solve the problems of long time, short time, large processing capacity, etc., to save manufacturing costs, save production costs, and large processing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

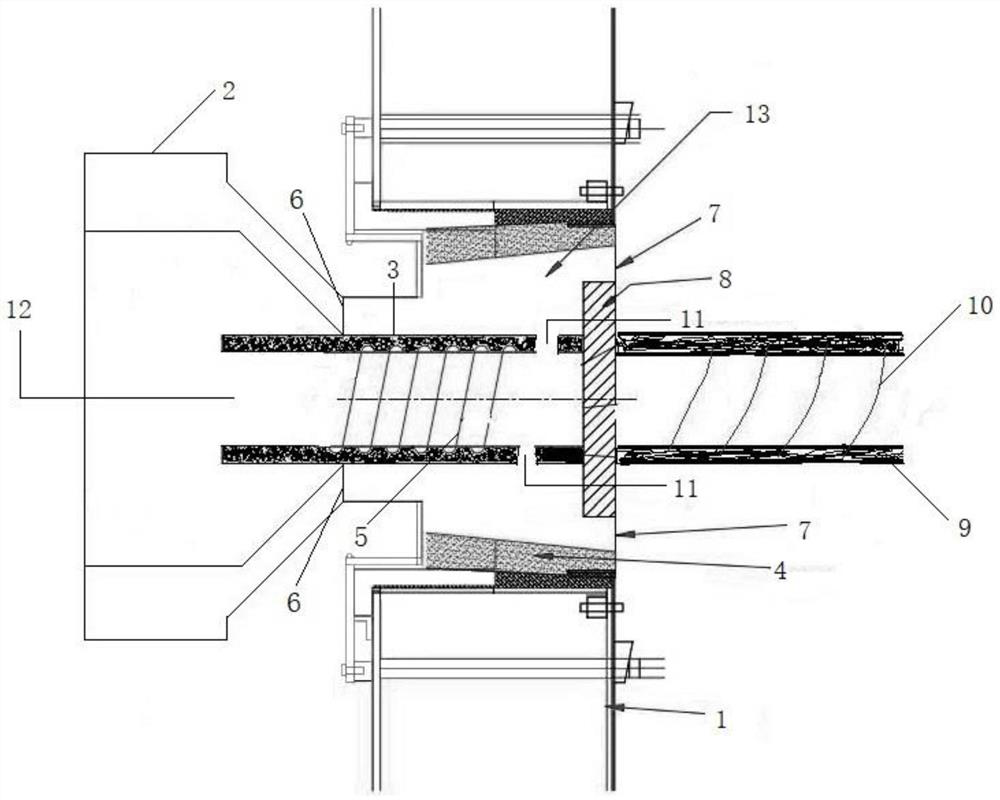

[0026] like figure 1 The shown medium-frequency heat-accumulating-based medium barrier temperature field furnace includes a furnace rack 1, a cyclone feeding device 2 located in the middle of the furnace rack, a first high-temperature resistant heating pipe 3 located on the cyclone feeding device, and a cyclone The furnace wall 4 in front of the feeding device and close to the inner wall of the furnace frame and the medium barrier plate arranged between the furnace walls; the first high temperature resistant heating pipe is fixed in the center of the cyclone feeding device; the first high temperature resistant heating pipe It is a hollow tube, and a first intermediate frequency heating coil 5 is fixed on the inner wall of the first high temperature resistant heating tube.

[0027] Wherein, the distance between the medium barrier plate and the cyclone feeding device is 5cm-1000cm, and the overall inner diameter of the medium barrier temperature field furnace is 80cm-5000cm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com