Method for Separating Boron

A boron complex and solution technology, applied in the field of boron separation, can solve the problems of complex process, high production cost, large consumption of resin, etc., and achieve the effects of simple process steps, wide application range and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

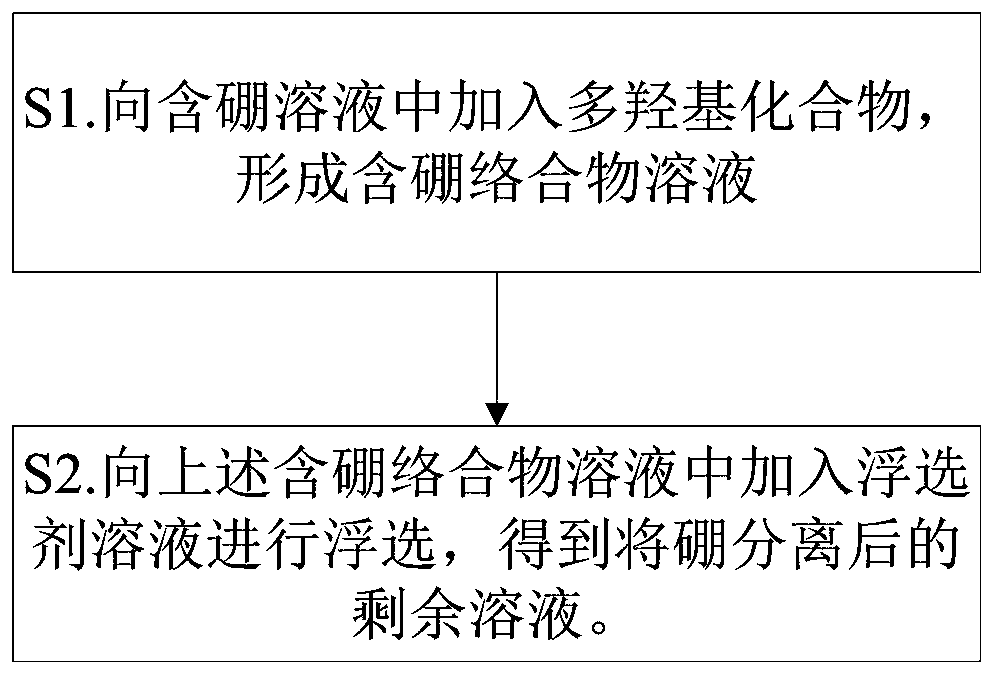

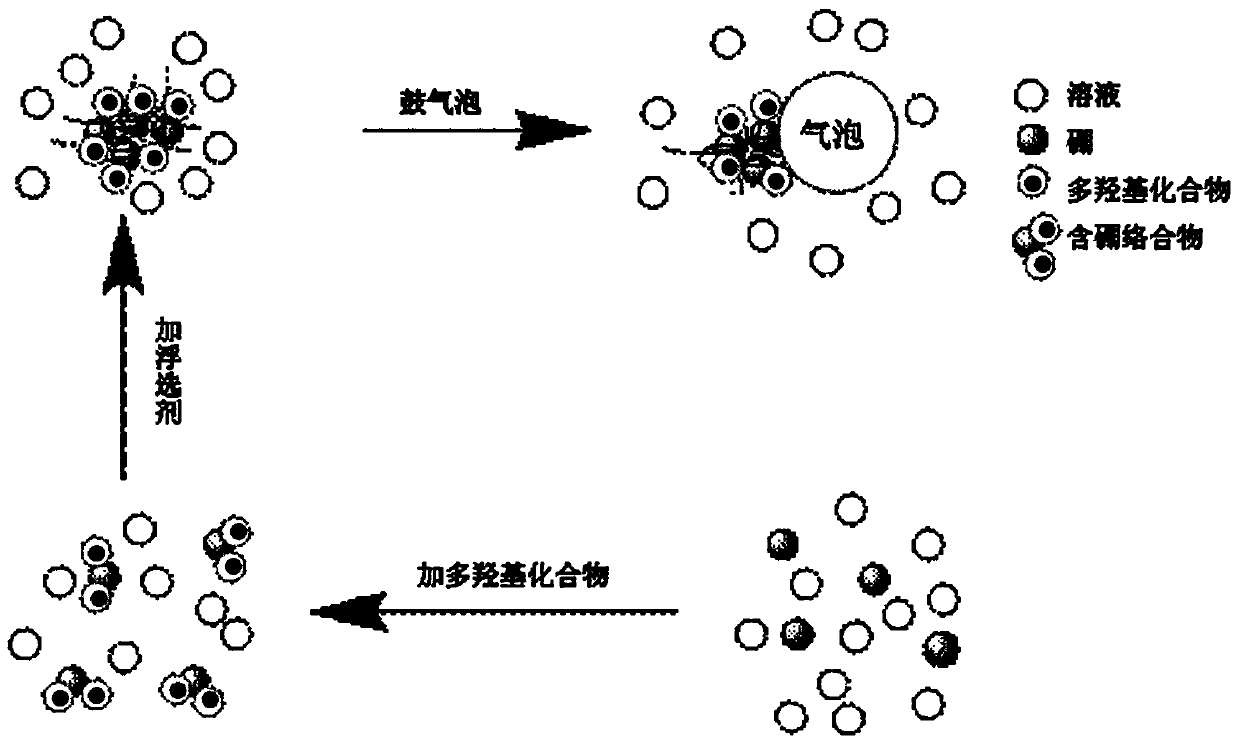

[0036] The present embodiment provides a method for separating boron, comprising the following steps:

[0037] S1. Prepare 520mL solution containing 0.03mol / L boron, add 71.04g mannitol, adjust the pH of the solution to 2.164, and form a boron-containing complex solution.

[0038] S2. Weigh 2g of sodium dodecylbenzenesulfonate and dissolve it in 10mL of secondary water to form a flotation agent solution. Pour the above-mentioned boron-containing complex solution and flotation agent solution into the flotation cell, close the air valve, stir, adjust the stirring speed to 1800r / min, and stir for 10min; The bubbling speed is 1500r / min; the boron-containing complex solution is combined with the flotation agent solution, and floats to the top layer of the reaction system with the bubbles to form a foam layer, and the top foam layer is scraped off to obtain the remaining solution after boron is separated.

[0039] The remaining solution after boron separation is measured by acid-ba...

Embodiment 2

[0041] The present embodiment provides a method for separating boron, comprising the following steps:

[0042] S1. Prepare a 520mL solution containing 0.03mol / L boron, add 28.42g mannitol, adjust the pH value of the solution to 4.067, and form a boron-containing complex solution.

[0043] S2. Take 1 portion of 3g sodium dodecylbenzenesulfonate and dissolve it in 10mL of secondary water to form a flotation agent solution. Pour the above-mentioned boron-containing complex solution and flotation agent solution into the flotation cell, close the air valve, stir, adjust the stirring speed to 1400r / min, and stir for 2min; The bubbling speed is 1500r / min; the boron-containing complex solution is combined with the flotation agent solution, and floats to the top layer of the reaction system with the bubbles to form a foam layer, and the top foam layer is scraped off to obtain the remaining solution after boron is separated.

[0044] The remaining solution after boron separation is mea...

Embodiment 3

[0046] The present embodiment provides a method for separating boron, comprising the following steps:

[0047] S1. Prepare a 520mL solution containing 0.03mol / L boron, add 42.63g mannitol, adjust the pH of the solution to 7.165, and form a boron-containing complex solution.

[0048] S2. Take 1 portion of 4g sodium dodecylbenzenesulfonate and dissolve it in 10mL of secondary water to form a flotation agent solution. Pour the above-mentioned boron-containing complex solution and flotation agent solution into the flotation cell, close the air valve, stir, adjust the stirring speed to 1600r / min, and stir for 5min; Select, the bubbling speed is 1800r / min; obtain the remaining solution after boron is separated.

[0049] The remaining solution after boron separation is measured by acid-base titration, after flotation, the concentration of boron in the remaining solution after boron separation is 0.00478mol / L, and the removal rate of boron can reach 91.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com