Fluidized bed sludge incineration system and treatment method

A sludge incineration and fluidized bed technology, which is applied in the combustion method, incinerator, combustion type, etc., can solve the problems of secondary pollution, reduced sludge moisture content, non-environmental protection, etc., and achieves low cost and good separation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

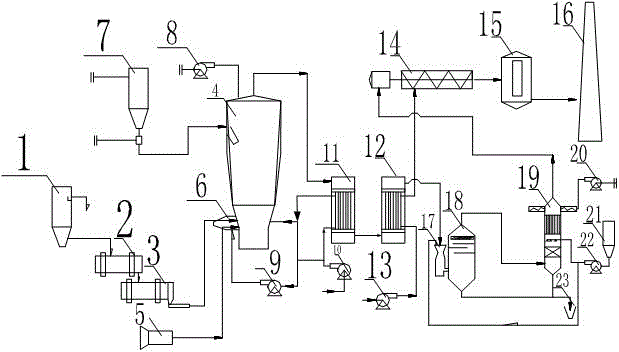

[0028] Such as figure 1 as shown,

[0029]The fluidized bed sludge incineration system includes a sludge incineration device, a two-stage heat exchange device, a washing and dust removal device, and a secondary combustion device. The sludge incineration device includes a fluidized bed incinerator 4, and the two-stage heat exchange device includes a primary exchange Heater 11 and secondary heat exchanger, the heat passage of primary heat exchanger 11 communicates with the top gas outlet of fluidized bed incinerator 4, the heat passage of primary heat exchanger 11 is also connected with the heat of secondary heat exchanger The channels are connected in series, the heat channel of the secondary heat exchanger is connected with the washing and dust removal device, and the washing and dust removal device is also connected with the secondary combustion device, the cold channel of the primary heat exchanger 11 is connected with the fluidized bed incinerator 4, and the secondary The ...

Embodiment 2

[0040] The processing method based on the above-mentioned fluidized bed sludge incineration system comprises the following steps:

[0041] A. Sludge drying step: the sludge in the sludge tank is dried after passing through a sludge dehydrator and a sludge dryer;

[0042] B, sludge incineration step: send the dried sludge in the previous step into the fluidized bed incinerator 4 for combustion;

[0043] C. Heat exchange step: input the waste gas particle mixture output from the top outlet of the fluidized bed incinerator 4 into the heat channel of the primary heat exchanger 11, and pass the heat through the heat channel and the cold channel of the primary heat exchanger 11 Exchange, absorb the heat of the waste gas particle mixture, and the absorbed heat flows back into the fluidized bed incinerator 4, and the cooled waste gas particle mixture flows into the heat channel of the next secondary heat exchanger, and passes through the heat channel of the secondary heat exchanger. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com