A device assembly formed by arranging a heat exchanger of a heat pump of a laundry dryer

A heat exchanger, dryer technology, used in washing devices, household clothes dryers, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

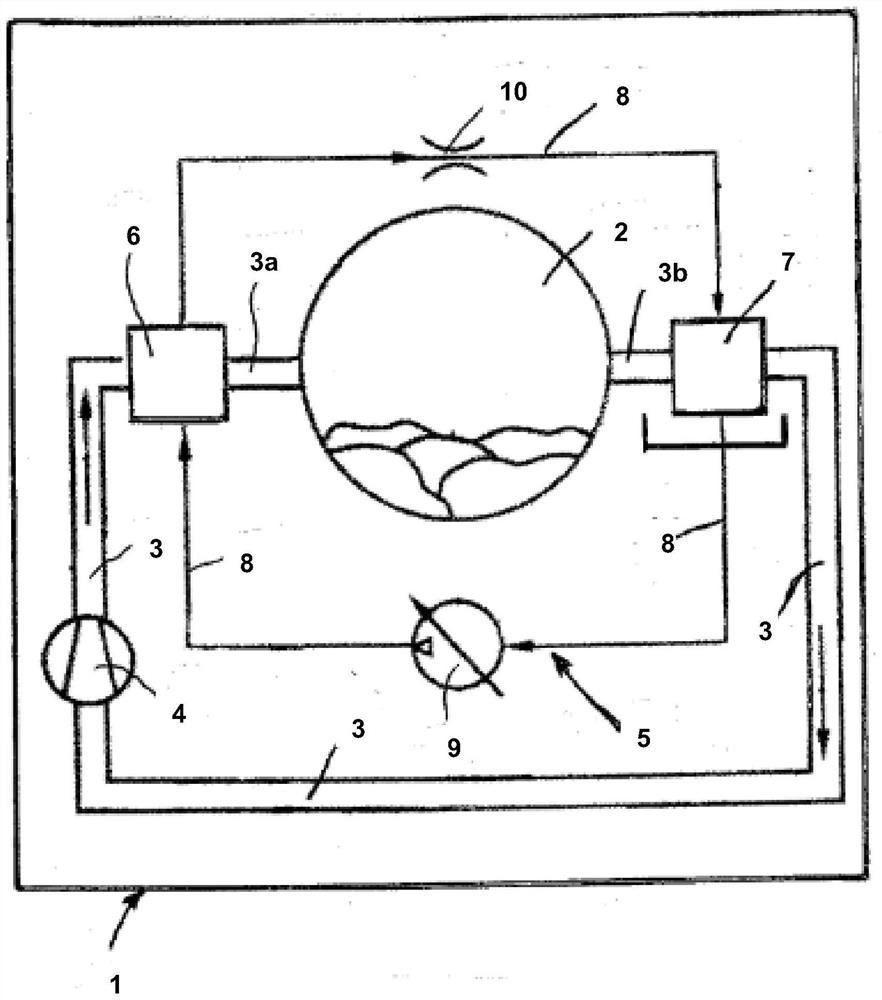

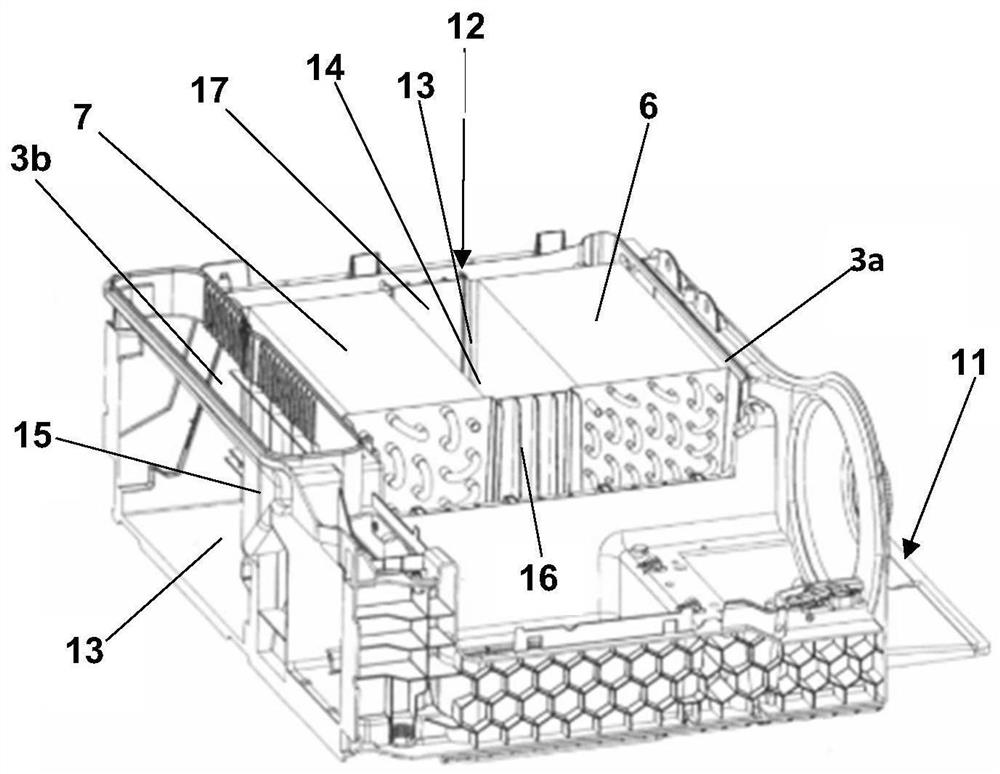

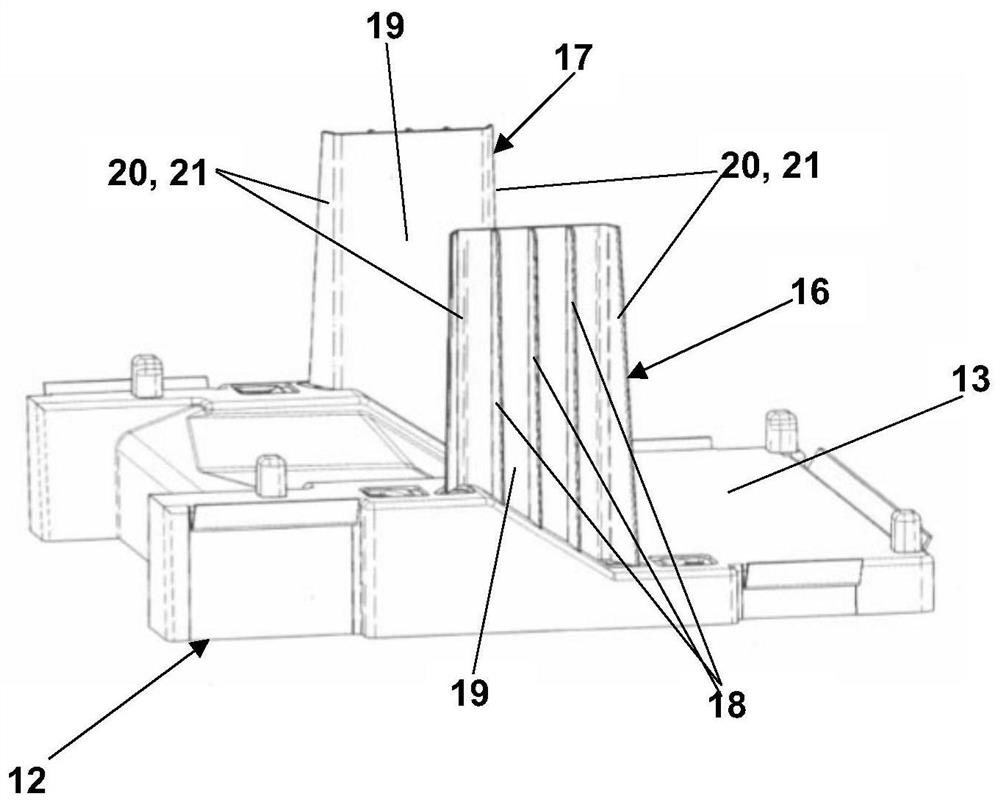

[0035] exist figure 1 In FIG. 1 , a laundry dryer is indicated by reference number 1 , which has a laundry drum 2 for receiving laundry to be dried. The laundry drum 2 is connected to the process air channel 3 of the process air system forming a circuit as a whole, wherein relatively hot, dry process air flows into the laundry drum 2 via the supply air section 3a of the process air channel 3 and The discharge air section 3b which passes through the process air channel 3 then flows out of the laundry drum 2 again as moist, water vapor-enriched process air (after it has absorbed the moisture from the laundry). A corresponding air flow inside the process air channel 3 is generated by a process air fan 4 .

[0036] A heat pump 5 interacting with the process air system of the laundry dryer 1 has a first heat exchanger 6 configured as a condenser and a second heat exchanger 7 configured as an evaporator. Here, the process air in the cooled and dry state, which is conveyed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com