Machine vision-based fabric defect detection system

A defect detection and machine vision technology, applied in the field of fabric inspection equipment, can solve the problems of low data transmission efficiency, high configuration requirements, and high transmission delay, and achieve the effect of improving transmission efficiency, improving overall speed, and reducing configuration requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

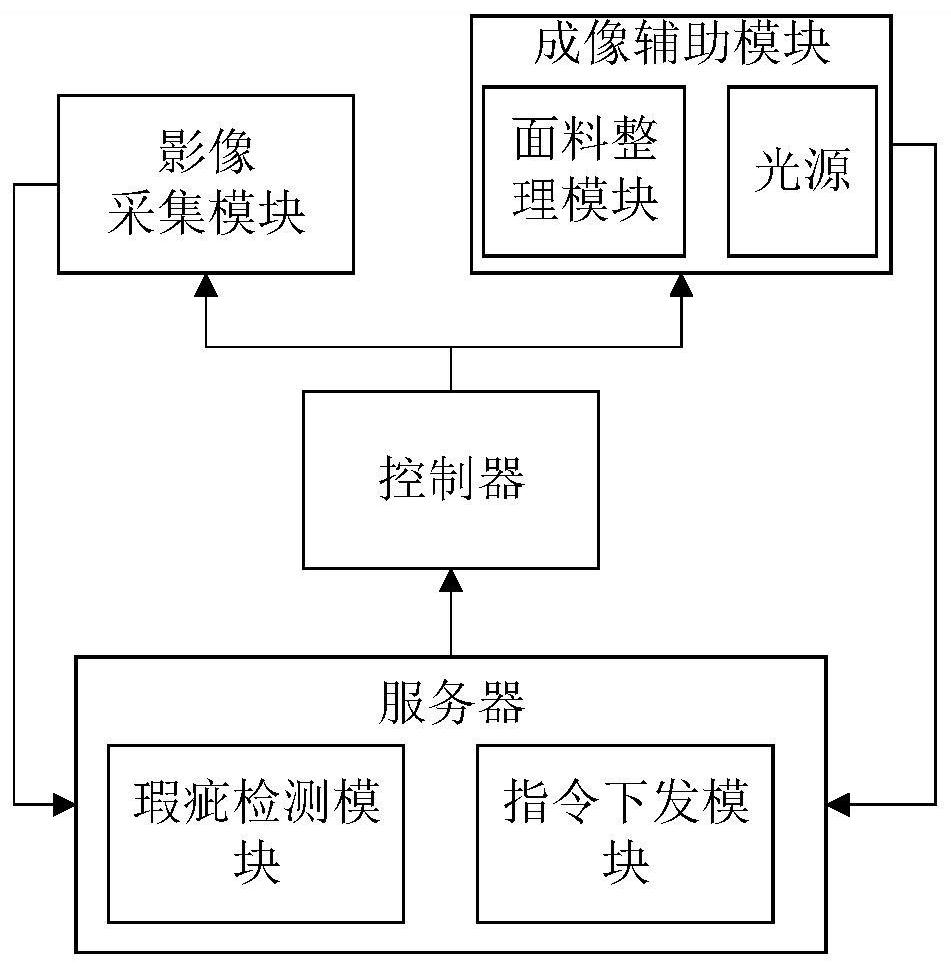

[0043] Embodiment 1 is basically as attached figure 1 Shown:

[0044] A fabric defect detection system based on machine vision includes an image acquisition module, an imaging auxiliary module, a controller and a server. In this embodiment, the controller is a single-chip microcomputer. The image acquisition module is connected to the controller and the server, and includes a data link and a control link between the image acquisition module and the server; the image acquisition module is directly connected to the server in the data link; in the control link, the server , the controller and the image acquisition module are connected in sequence.

[0045] In this embodiment, the image of the fabric is collected by the image acquisition module and sent to the server through the data link. In this embodiment, the image acquisition module is a camera array composed of multiple area array cameras horizontally. The imaging auxiliary module includes a fabric finishing module and a l...

Embodiment 2

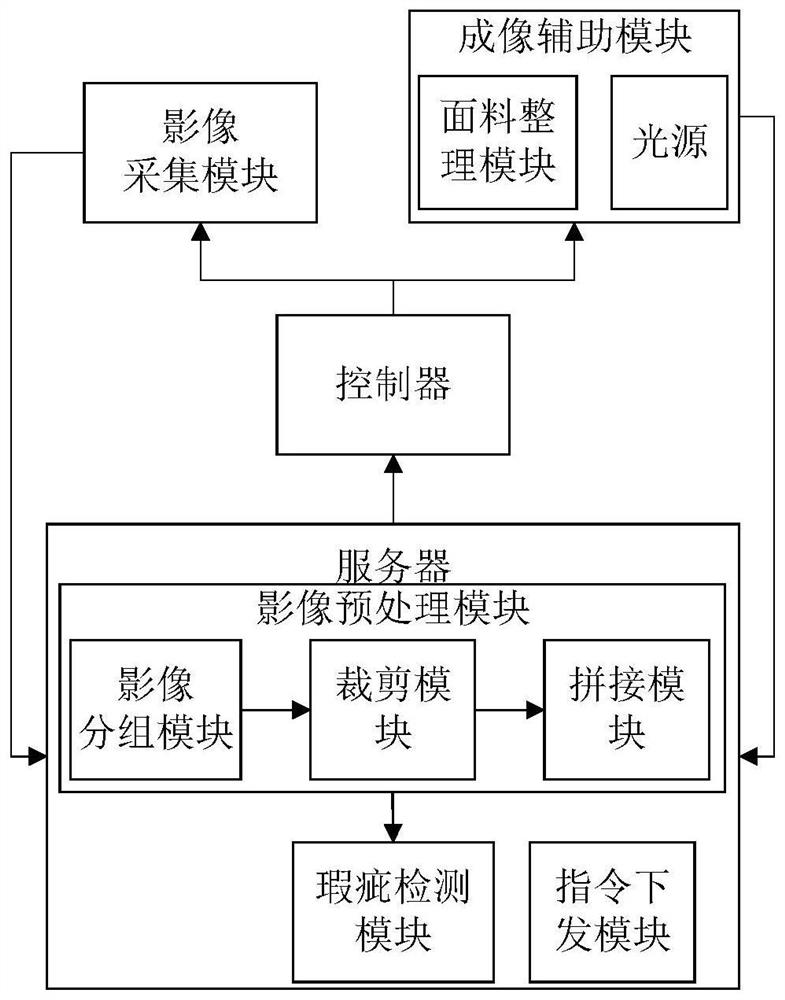

[0050] Embodiment 2 is basically as attached figure 2 Shown:

[0051] The difference between Embodiment 2 and Embodiment 1 is that the server also includes an image preprocessing module, which is used to receive the images sent by the image acquisition module and group the received images; images are stitched together.

[0052] The image preprocessing module includes an image grouping module, a cropping module and a splicing module; the image acquisition module is used to simultaneously send the images collected by the camera array at the same time point to the server. The image grouping module receives the images sent by the image acquisition module, and groups the images according to the time points when the images are sent by the camera array; the cropping module compares the features of the images of the same group, and generates stitching lines for splicing the images of the same group, Cut the images of the same group along the stitching line; the splicing module stit...

Embodiment 3

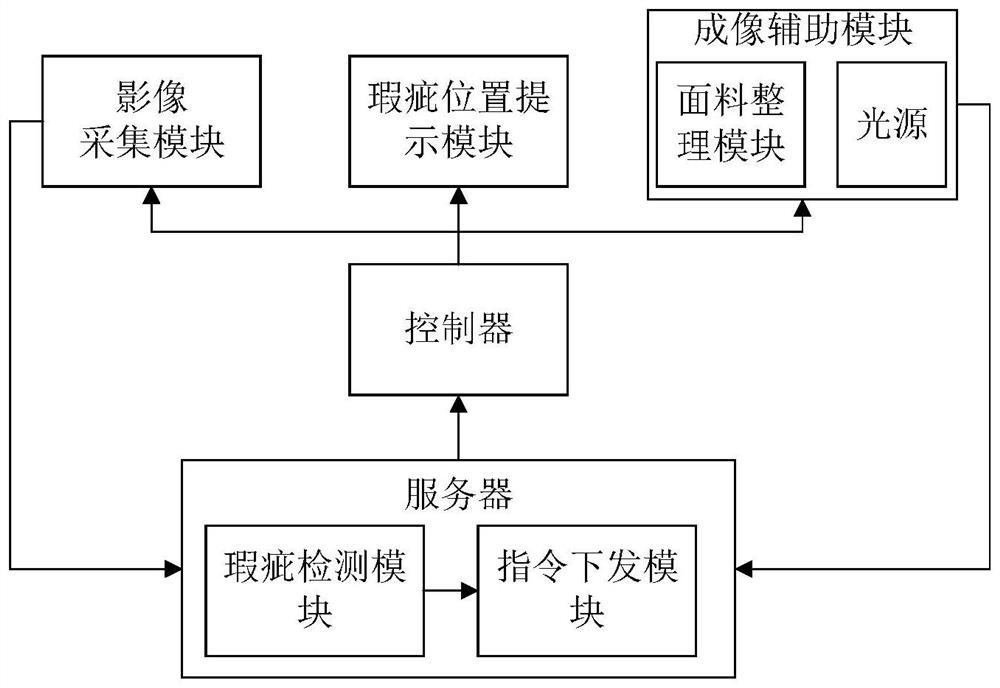

[0055] Embodiment 3 is basically as attached image 3 Shown:

[0056] The difference between embodiment 3 and embodiment 1 is that it also includes a defect position prompting module, the defect position prompting module includes a lighting device, and the instruction issuing module is also used to send to the control unit according to the defect detection result generated by the defect detection module The controller issues instructions to control the operating parameters of the defect location prompt module, and the defect location prompt module is used to control the operating parameters of the lighting device according to the instructions issued by the controller, and to indicate the specific area where the defect is located through the light, thus realizing Quick localization of the actual location of the defect on the fabric surface.

[0057] The defect location prompt module includes a parameter generation module and a light control module. The defect detection result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com