Construction method for temporarily replacing foundation pit crossing concrete pipe with steel pipe in deep foundation pit construction

A technology of concrete pipes and construction methods, which is applied in the direction of sewer pipe systems, water supply devices, waterway systems, etc., can solve the problems of difficulty in relocation, long relocation period, and limited paths, and achieve high construction efficiency and short construction period , The effect of saving communication costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

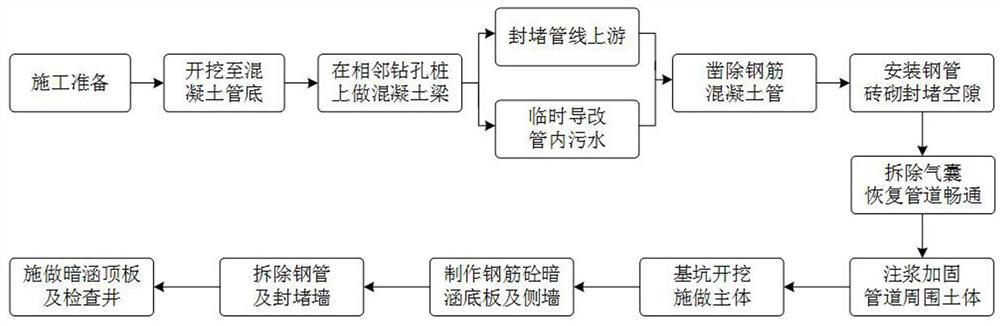

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] During the construction of Jinyang Street Station (YDK15+4486.999~YDK15+718.299) of Taiyuan Rail Transit Line 2 at the No. 1 entrance and No. 2 entrance and exit of Line 2, the DN1500 sewage pipe across the foundation pit needs to be treated. Due to the pressure of the construction period Large, the cost of relocation is huge, and the construction period is long, so this method is selected to ensure the schedule and cost. Temporarily replacing concrete pipes with steel pipes saves 20 days of construction period and 1,169,600 yuan in costs compared with pipeline relocation, which also proves the safety and operability of the method of the present invention, and has achieved obvious economic and social benefits.

[0044] details as follows:

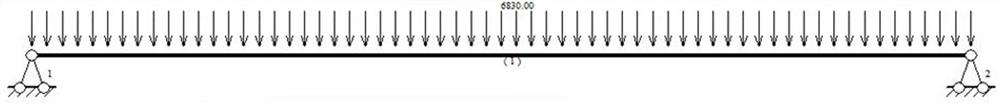

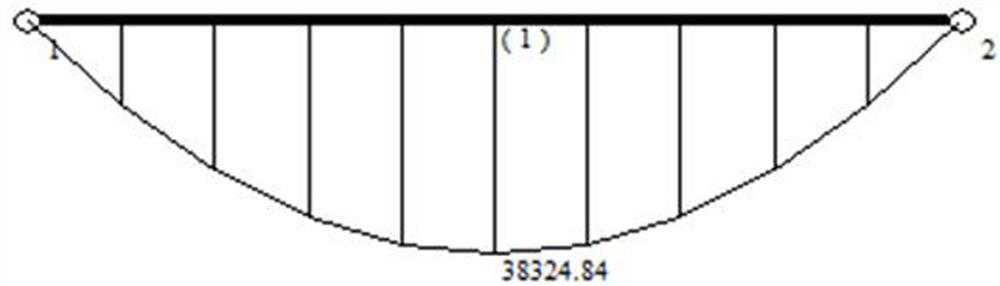

[0045] One, a kind of steel pipe temporarily replaces large-diameter, large-flow cross-foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com