Method for selecting measuring head of three-coordinate measuring machine

A three-coordinate measuring machine and measuring head technology, which is applied to measuring devices, instruments, etc., can solve problems such as the failure of the measuring head to be used normally, shorten the service life of the measuring head, and the falling off of the force measuring module, so as to ensure effective acquisition and shorten the measurement time. time, avoiding the effect of measuring angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

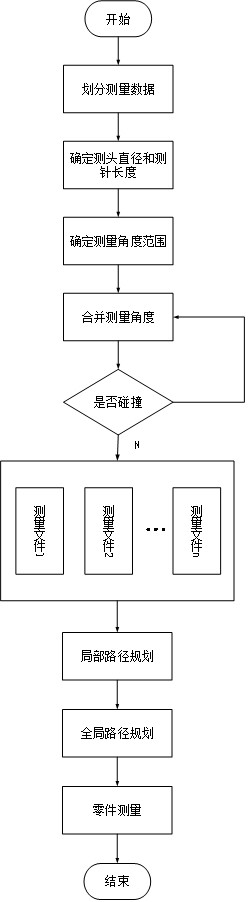

[0024] A method for CMM probe selection such as Figure 1-Figure 3 shown, including the following steps:

[0025] Step 1: Divide the measurement data: put the measurement data of the same feature of the part to be tested in the same data file;

[0026] Step 2: Determine the probe diameter and stylus length: In the data file, within the optional standard range of the CMM, determine the probe diameter and stylus length based on the principle of the length of the ball and rod;

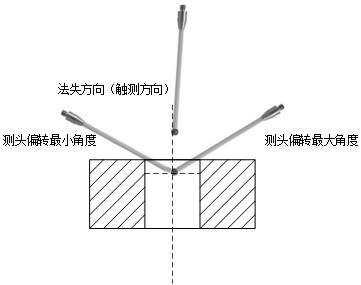

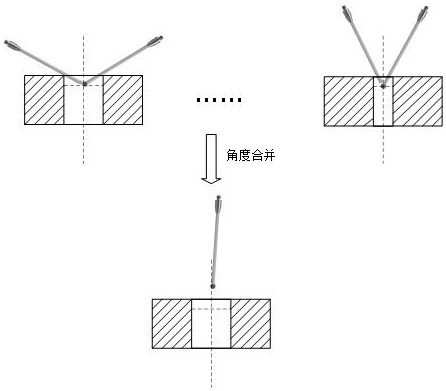

[0027] Step 3: Initially determine the measurement angle and combine the measurement angles: eg figure 2 As shown in , the touch direction of the probe is preliminarily determined by the direction of the measuring point, and the deflection angle range of the probe is preliminarily determined based on the principle of not touching the part to be tested; image 3 As shown, and then further based on the principle of non-collision parts and tooling, the initially determined deflection angle ranges of multi...

Embodiment 2

[0031] This embodiment is optimized on the basis of Embodiment 1. In the step 2, select the probe with the largest probe diameter to determine the diameter of the side probe, so as to improve the early triggering of the probe; select the longest probe to determine the diameter of the probe. length to increase the measurable characteristics of the stylus on the part being tested.

[0032] Further, the deflection angle of the probe is determined from the measurement angle determined in step 3, so as to ensure that the geometric features of the part to be measured are detected at the same probe angle. This embodiment overcomes unforeseen technical problems such as unreasonable selection of the measuring head, which will cause the force measuring module to fall off, the measuring head cannot be used normally to obtain effective signals, affect the measurement accuracy, and shorten the service life of the measuring head.

[0033] Other parts of this embodiment are the same as those...

Embodiment 3

[0035] A method for CMM probe selection such as figure 1 shown, including the following steps:

[0036] Step 1: Divide the measurement data: put the measurement data of the same feature of the part to be tested in the same data file;

[0037] Step 2: Determine the probe diameter and stylus length: In the data file, within the optional standard range of the CMM, determine the probe diameter and stylus length based on the principle of the length of the ball and rod;

[0038] Step 3: Initially determine the measurement angle and combine the measurement angles: eg figure 2 As shown in , the touch direction of the probe is preliminarily determined by the direction of the measuring point, and the deflection angle range of the probe is preliminarily determined based on the principle of not touching the part to be tested; image 3 As shown, and then further based on the principle of non-collision parts and tooling, the initially determined deflection angle ranges of multiple probes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com